Iron-copper oxide/copper base electrode material and preparation method thereof

A technology of electrode materials and oxides, applied in the field of iron-copper oxide/copper-based electrode materials and their preparation, can solve the problem of low specific capacity of carbon materials and conductive polymers, restricting the matching of positive and negative electrodes of supercapacitors, and affecting the energy of supercapacitors Density and other issues, to achieve good structural and mechanical properties, easy to scale up production and preparation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

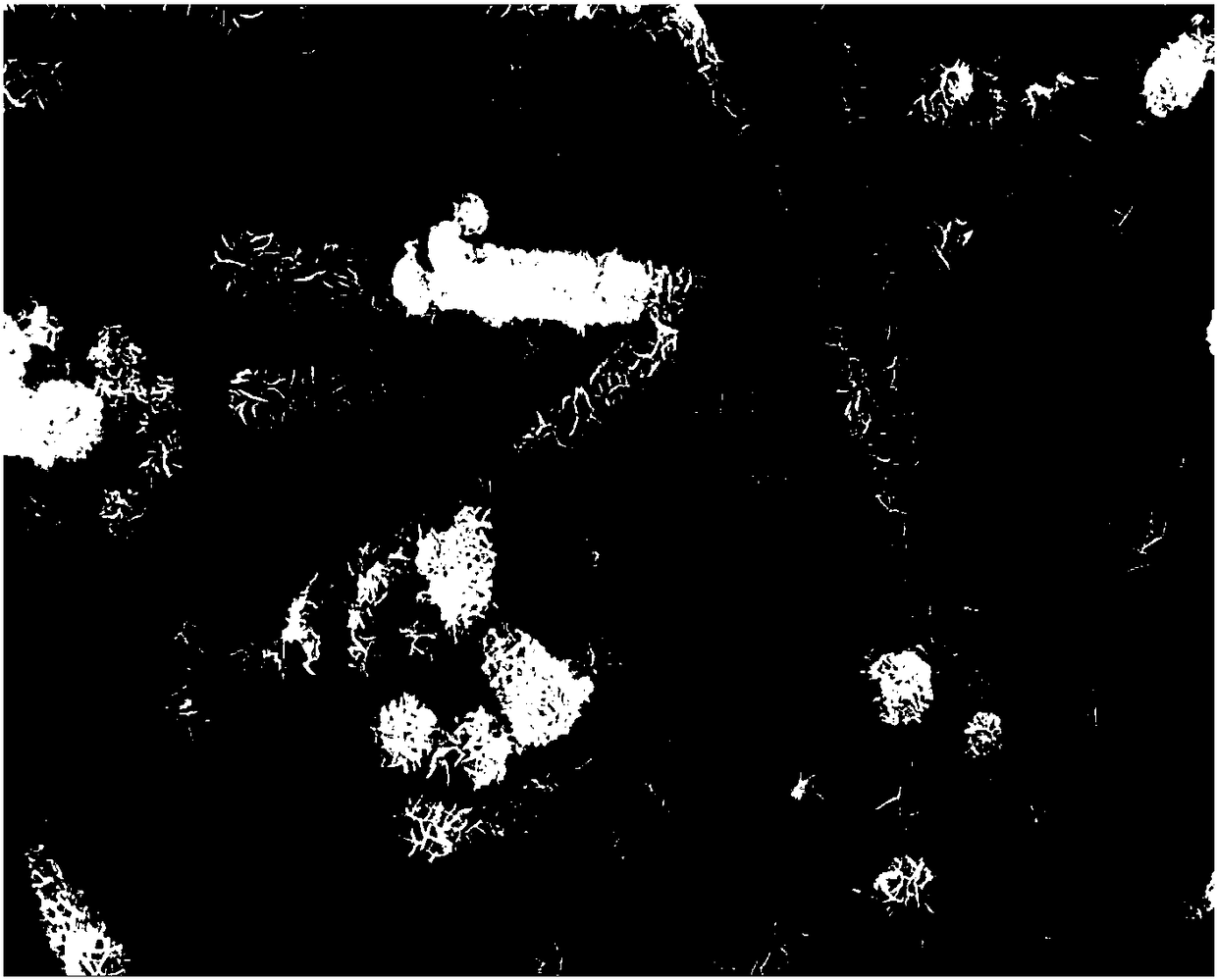

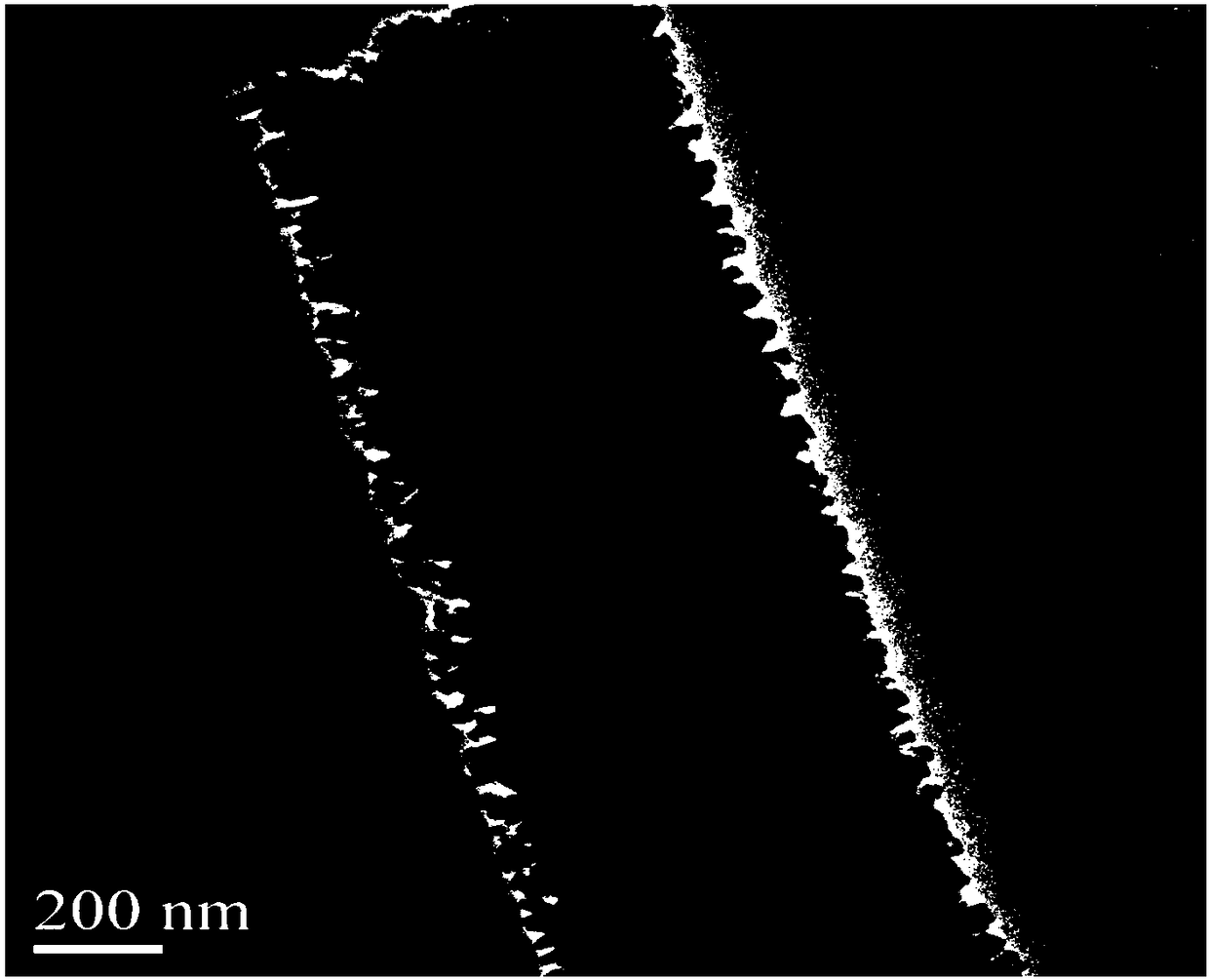

[0039] A. Preparation of copper hydroxide / copper-containing metal substrate

[0040] Cut the foamed copper with a purity greater than 99% into 4.0*3.0cm 2 The size of the slice is ultrasonically cleaned with 10% hydrochloric acid for 5 minutes, then rinsed with deionized water and absolute ethanol, and dried in an oven at 60°C for use. Weigh 10.0g of sodium hydroxide and 2.28g of ammonium persulfate and dissolve them in 100mL of deionized water to make the concentration 2.5mol L respectively. -1 And 0.1mol L -1 After immersing the pretreated foamed copper substrate in the mixed solution for 20 minutes, take it out, rinse with deionized water, and dry it in an oven at 60°C to obtain copper hydroxide nanorods grown on the foamed copper substrate. Material, namely Cu(OH) 2 / Foam copper.

[0041] B. Weigh 1.515g of ferric nitrate nonahydrate, and dissolve it in 50mL of deionized water as an electrolyte solution. The Cu(OH) obtained in step A 2 / Foam copper as the working electrode, Pt ...

Embodiment 2

[0046] A. Choose copper mesh with a purity greater than 99% and cut it into 4.0*3.0cm 2 The size of the slice is ultrasonically cleaned with 10% hydrochloric acid for 5 minutes, then rinsed with deionized water and absolute ethanol, and dried in an oven at 60°C for use. Weigh 10.0g of sodium hydroxide and 2.28g of ammonium persulfate and dissolve them in 100mL of deionized water to make the concentration 2.5molL respectively -1 And 0.1mol L -1 The pretreated copper mesh is immersed in the mixed solution for 20 minutes and then taken out, rinsed with deionized water, and dried in an oven at 60°C to grow copper hydroxide nanorod arrays on the surface of the copper mesh substrate. Namely Cu(OH) 2 / Copper mesh

[0047] B. Weigh 1.25 g of ferric chloride and 0.5 g of ferrous sulfate, and dissolve them in 50 mL of deionized water as an electrolyte solution. The Cu(OH) obtained in step A 2 / Copper mesh is used as the working electrode, Pt is the counter electrode, and Ag / AgCl is the ref...

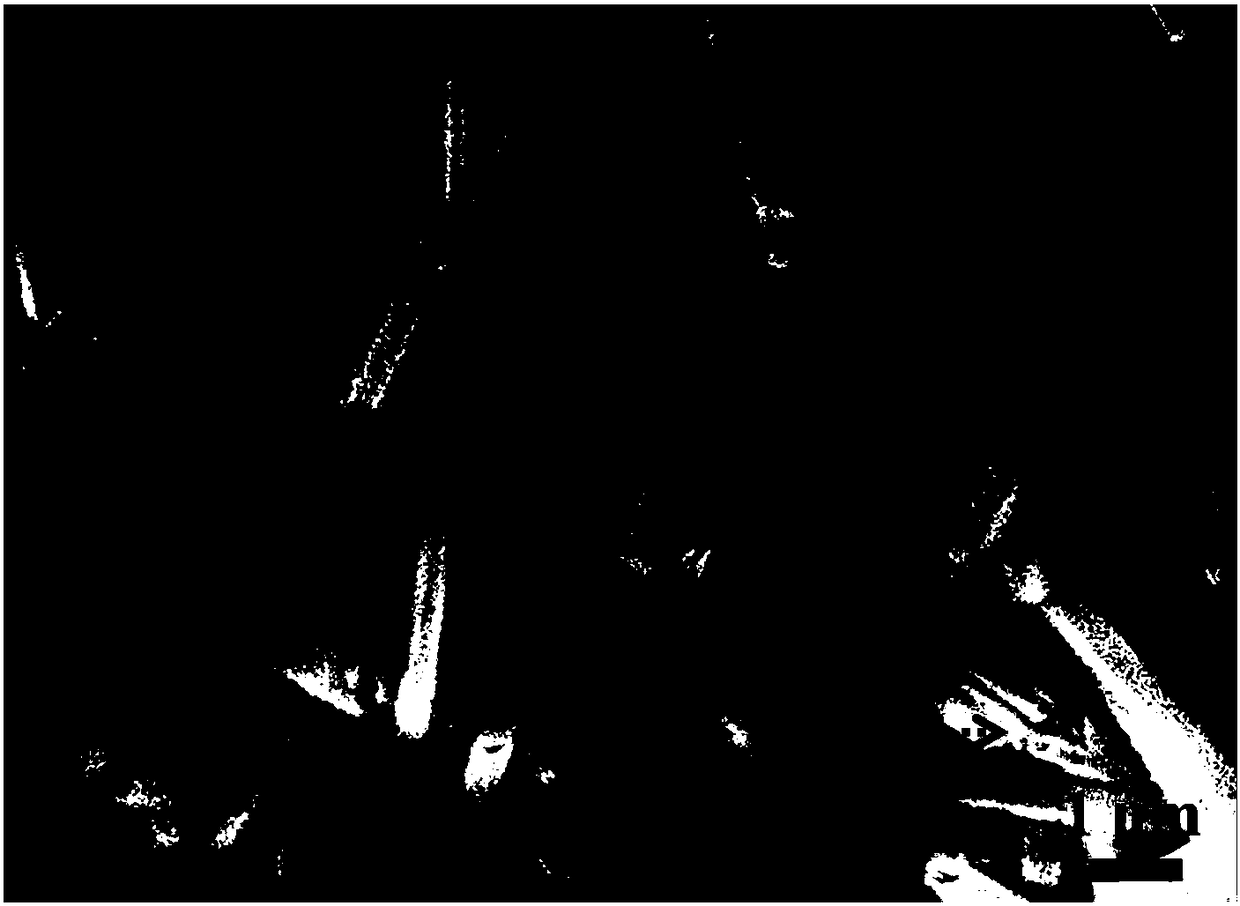

Embodiment 3

[0052] A. Choose copper sheet with a purity greater than 99% and cut it into 4.0*3.0cm 2 The size of the slice is ultrasonically cleaned with 10% hydrochloric acid for 5 minutes, then rinsed with deionized water and absolute ethanol, and dried in an oven at 60°C for use. Weigh 10.0g of sodium hydroxide and 2.28g of ammonium persulfate and dissolve them in 100mL of deionized water to make the concentration 2.5molL respectively -1 And 0.1mol L -1 The pretreated copper mesh is immersed in the mixed solution for 20 minutes and then taken out, rinsed with deionized water, and dried in an oven at 60°C to grow copper hydroxide nanorod arrays on the surface of the copper substrate. Namely Cu(OH) 2 / Copper sheet.

[0053] B. Weigh 2.5 g of ferric chloride and dissolve it in 50 mL of deionized water as an electrolyte solution. The Cu(OH) obtained in step A 2 / Copper as the working electrode, Pt as the counter electrode and Ag / AgCl as the reference electrode. Under the condition of -1.0V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com