MXene/conductive polymer composite aerogel and preparation method thereof

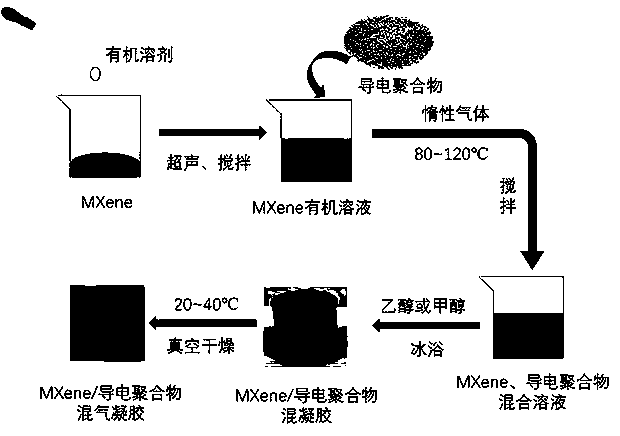

A conductive polymer and composite aerogel technology, which is applied in the field of MXene/conductive polymer composite aerogel and its preparation, can solve the problems of affecting the cycle performance of materials, poor high current discharge performance, slow ion migration speed, etc. The effect of increasing surface utilization, mitigating structural collapse, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Synthesis of MXene

[0039] Measure 2.5ml deionized water and 7.5ml HCl into a 100ml plastic bottle, add 1g LiF, stir for 5min until completely dissolved. 1g Ti 3 AlC 2 While stirring, add it into the above-mentioned plastic bottle, place it in a constant temperature water bath at 35°C and stir for 24 hours. Then the above product was centrifuged with a centrifuge, the upper light green supernatant was poured out, and water was added to stir and mix well. Centrifuge again, take out the upper layer liquid, promptly obtain MXene aqueous solution. The MXene aqueous solution is suction filtered and vacuum-dried to obtain the MXene solid matter ( figure 2 shown as neatly stacked MXene sheets);

[0040] The prepared 50mg MXene solid substance was added to 100ml NMP solvent, and ultrasonically stirred repeatedly to obtain a black uniformly dispersed MXene organic solution of 0.5mg / ml;

[0041] B. Synthesis of MXene / conductive polymer composite airgel

[0042] Take 1...

Embodiment 2

[0048] A. Synthesis of MXene

[0049] Measure 5ml of deionized water and 22.5ml of HCl into a 100ml plastic bottle, add 1.5g of LiF, stir for 3min until completely dissolved. 1.5g Ti 3 AlC 2 While stirring, add it into the above-mentioned plastic bottle, place it in a constant temperature water bath at 15°C and stir for 35 hours. Then the above product was centrifuged with a centrifuge, the upper light green supernatant was poured out, and water was added to stir and mix well. The supernatant was poured out by centrifugation and the operation was repeated 6 times, and the supernatant was taken out to obtain the MXene aqueous solution. The MXene aqueous solution is subjected to freeze-drying treatment to obtain MXene solid matter;

[0050] The prepared 100mg MXene solid substance was added to 20ml NMP solvent, and ultrasonically stirred repeatedly to obtain a 5mg / ml black uniformly dispersed MXene organic solution;

[0051] B. Synthesis of MXene / conductive polymer composit...

Embodiment 3

[0057] A. Synthesis of MXene

[0058] Measure 3ml of deionized water and 11ml of HCl into a 100ml plastic bottle, add 1.2g of LiF, stir for 3min until completely dissolved. 1.2g Ti 3 AlC 2 While stirring, add it into the above-mentioned plastic bottle, place it in a constant temperature water bath at 25°C and stir for 30 hours. Then the above product was centrifuged with a centrifuge, the upper light green supernatant was poured out, and water was added to stir and mix well. The supernatant was poured out by centrifugation and the operation was repeated 3 times, and the supernatant was taken out to obtain the MXene aqueous solution. The MXene aqueous solution is subjected to suction filtration and vacuum drying to obtain MXene solid matter;

[0059] The prepared 50mg MXene solid substance was added to 20ml NMP solvent, and ultrasonically stirred repeatedly to obtain a black uniformly dispersed MXene organic solution of 2.5mg / ml;

[0060] B. Synthesis of MXene / conductive p...

PUM

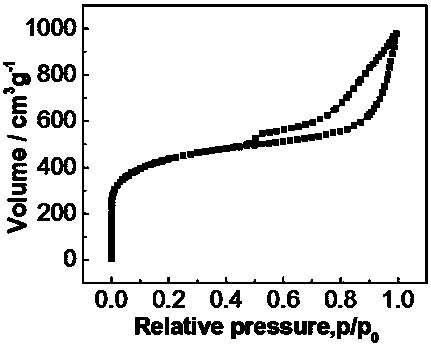

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com