Method for manufacturing quaternary ammonium salt terminated hydrophilic block silicone oil

A technology of hydrophilic block and manufacturing method, applied in textiles, papermaking, fiber processing, etc., can solve the problems of pipeline corrosion, seriousness, complicated process, etc., and achieve the effects of low cost, smooth hand feeling, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) In a 1000L reaction kettle equipped with a stirrer, a nitrogen gas feeding device, and a thermometer, add 500 kg of octamethylcyclotetrasiloxane (produced by Jiangxi Lanxinghuo Organic Silicon Co., Ltd.) and end epoxy silicone oil to extend the chain Agent (number average molecular weight is 1000, produced by Changzhou Guanghua Chemical New Material Co., Ltd.) 60 kilograms, catalyst tetramethylammonium hydroxide (produced by Yixing Kailida Chemical Co., Ltd.) 0.5 kilograms, at 100 ℃, react 4 Hours, the temperature was raised to 140° C. to remove the catalyst to obtain a linear silicone oil intermediate with epoxy groups at both ends. Cool down to 40°C, add 25 kg of polyethylene glycol diglycidyl ether (molecular weight 400), 15 kg of 3-dimethylamino-1-propylamine, and 50 kg of isopropanol while stirring, and heat up to 80°C to react 7 hour, lower the temperature to 40°C, add 20 kg of glacial acetic acid, stir for 20 minutes, cool down to room temperature and dischar...

Embodiment 2

[0025] (1) in the 1000L reactor that stirrer, nitrogen feed device, thermometer are housed, add 600 kilograms of octamethylcyclotetrasiloxane and 72 kilograms of terminal epoxy silicone oil chain extender (number average molecular weight is 1000), Catalyst 0.6 kg of tetramethylammonium hydroxide, react at 100°C for 4 hours, heat up to 140°C to remove the catalyst to obtain a linear silicone oil intermediate with epoxy groups at both ends. Cool down to 40°C, add 30 kg of polyethylene glycol diglycidyl ether (molecular weight 600), 18 kg of 3-dimethylamino-1-propylamine, and 60 kg of isopropanol while stirring, and heat up to 80°C to react 7 hour, lower the temperature to 40°C, add 24 kg of glacial acetic acid, stir for 20 minutes, lower to room temperature and discharge to obtain a quaternary ammonium salt-terminated hydrophilic block silicone oil.

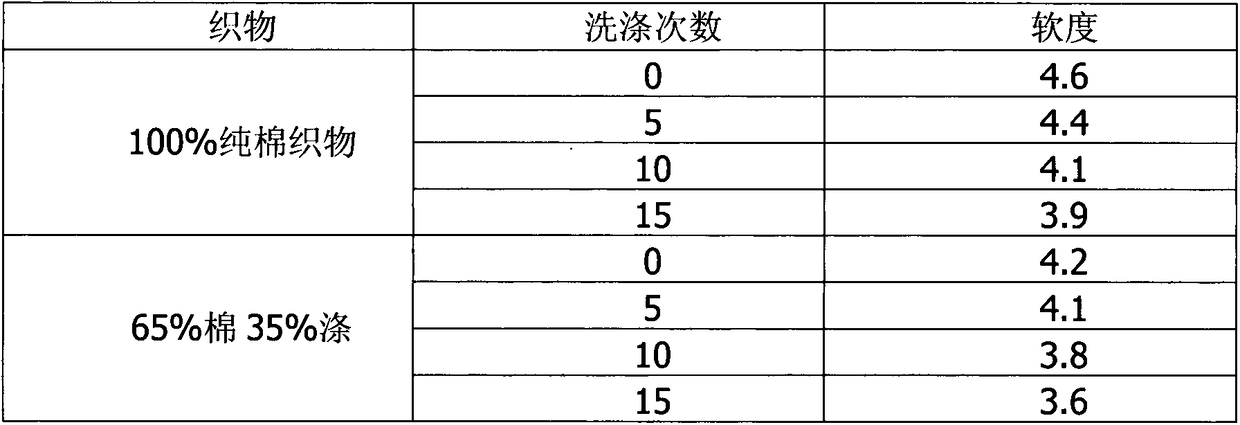

[0026] The quality detection data of the hydrophilic block silicone oil terminated by the quaternary ammonium salt of the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com