A kind of preparation method of hexafluoro-2-butyne

A technology of butyne and hexachlorobutadiene is applied in the field of preparation of hexafluoro-2-butyne, and can solve the problems of difficulty in obtaining 2-butyne diacid, high raw material price of sulfur tetrafluoride, unsuitability for industrialization and the like , to achieve the effect of low cost, less three waste emissions, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

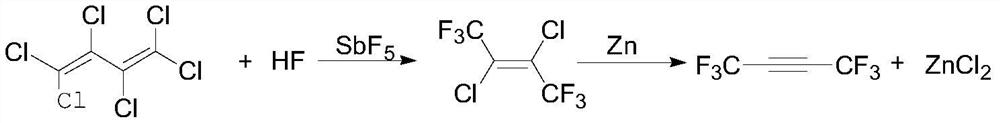

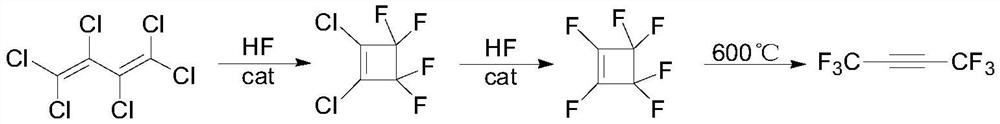

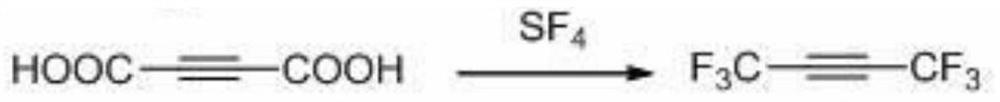

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In a 2L stainless steel reaction kettle with a condenser, add 260g of hexachlorobutadiene, 780g of sulfolane, and 348g of potassium fluoride, raise the temperature to 100°C for reaction, collect the gas phase reaction products, wash with water, wash with alkali, and rectify to obtain hexafluoro- 2-butyne product, the product is sampled and analyzed by gas chromatography, the conversion rate of raw material hexachlorobutadiene is 99%, and the product selectivity is 96%.

Embodiment 2

[0036] Add 260g of hexachlorobutadiene, 1,300g of diethylene glycol dimethyl ether, and 710g of chromium fluoride into a 2L stainless steel reaction kettle with a condenser, heat up to 250°C for reaction, and collect the gaseous reaction products and wash them with water and alkali 1. The hexafluoro-2-butyne product was obtained by rectification, and the product was sampled for gas chromatography analysis. The conversion rate of raw material hexachlorobutadiene was 99%, and the product selectivity was 95%.

Embodiment 3

[0038] Add 260g of hexachlorobutadiene, 800g of N-methylpyrrolidone, and 610g of zinc fluoride into a 2L stainless steel reaction kettle with a condenser, heat up to 150°C for reaction, collect the gas phase reaction products and wash with water, alkali, and rectify The hexafluoro-2-butyne product was obtained, and the product was sampled for gas chromatography analysis. The conversion rate of raw material hexachlorobutadiene was 99%, and the product selectivity was 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com