Special anti-scaling agent for petroleum refinery enterprise boiler and steam pocket and application of special anti-scaling agent

A scale inhibitor and refining technology, applied in the field of scale inhibitors, can solve the problems of unqualified steam and steam turbine condensate return water, scale layer can not be stripped and dispersed, long-term system operation risks, etc., to reduce free alkali and scale Effects of deposits, improved steam quality, and elimination of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

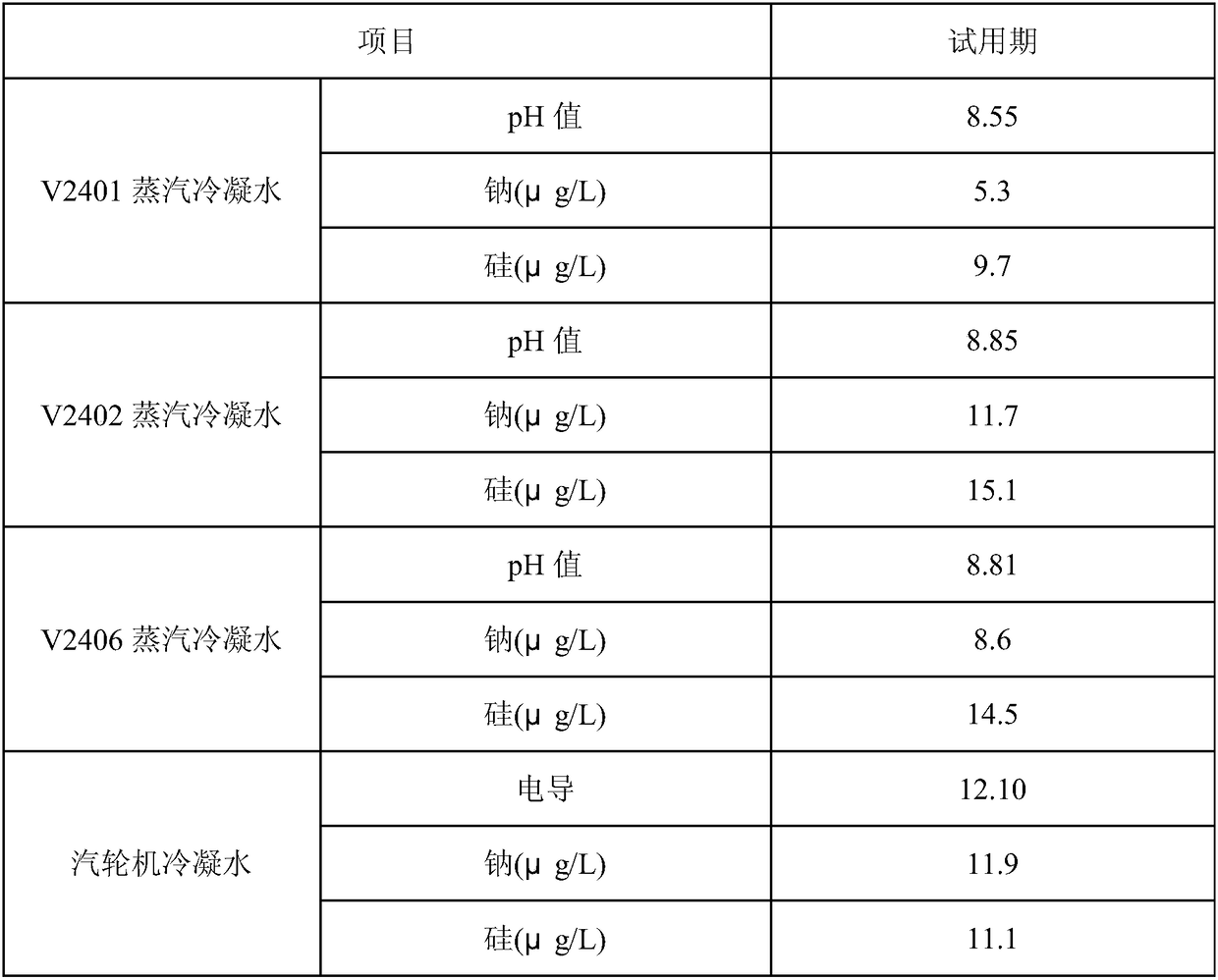

Examples

Embodiment 1

[0040] In the embodiment of the present invention, a special scale inhibitor for boilers and steam drums in petroleum refining and chemical enterprises, the raw materials in terms of weight percentage are:

[0041] Diethylenetriaminepentamethylenephosphonic acid 5%,

[0042] Amino Trimethylene Phosphonic Acid 5%,

[0043] Sodium EDTA 12%,

[0044] Polyacrylic acid 10%,

[0045] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 5%,

[0047] water balance.

Embodiment 2

[0049] In the embodiment of the present invention, a special scale inhibitor for boilers and steam drums in petroleum refining and chemical enterprises, the raw materials in terms of weight percentage are:

[0050] Diethylenetriaminepentamethylenephosphonic acid 5%,

[0051] Amino Trimethylene Phosphonic Acid 10%,

[0052] Sodium ethylenediamine tetramethylene phosphonate 10%,

[0053] Polyacrylic acid 10%,

[0054] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 5%,

[0055] Sodium Hydroxide 8%

[0056] water balance.

Embodiment 3

[0058] In the embodiment of the present invention, a special scale inhibitor for boilers and steam drums in petroleum refining and chemical enterprises, the raw materials in terms of weight percentage are:

[0059] Diethylenetriaminepentamethylenephosphonic acid 8%,

[0060] Amino Trimethylene Phosphonic Acid 8%,

[0061] Sodium EDTA 15%,

[0062] Polyacrylic acid 10%,

[0063] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 10%,

[0064] Sodium Hydroxide 10%

[0065] water balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com