Transparent wood with optical regulation and control function and preparation method thereof

A technology for optical control and transparent wood, which is used in wood treatment, impregnating wood, manufacturing tools, etc., to achieve the effect of low equipment requirements, good transparency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation of delignified wood substrates. The invention removes the lignin in the wood matrix through chemical treatment, and then obtains the delignified wood matrix after drying. Alternatively, the lignin in the wood matrix is firstly removed by chemical treatment, and then undergoes hydrophobic and lipophilic modification treatment and drying treatment to obtain the delignified wood matrix. The preparation method of the delignified wood substrate in the present invention includes but not limited to the above two methods.

[0035] The lignin in the wood matrix is removed by chemical treatment to obtain a delignified wood matrix. Specifically, the lignin in the wood is removed by soaking in a chemical reagent, that is, the wood substrate is placed in a chemical reagent and reacted at 25-100° C. for 1-10 hours. The chemical reagent used can be selected from at least one of hydrogen peroxide, a mixed solution of sodium hypochlorite and sodium hydroxide, or perchl...

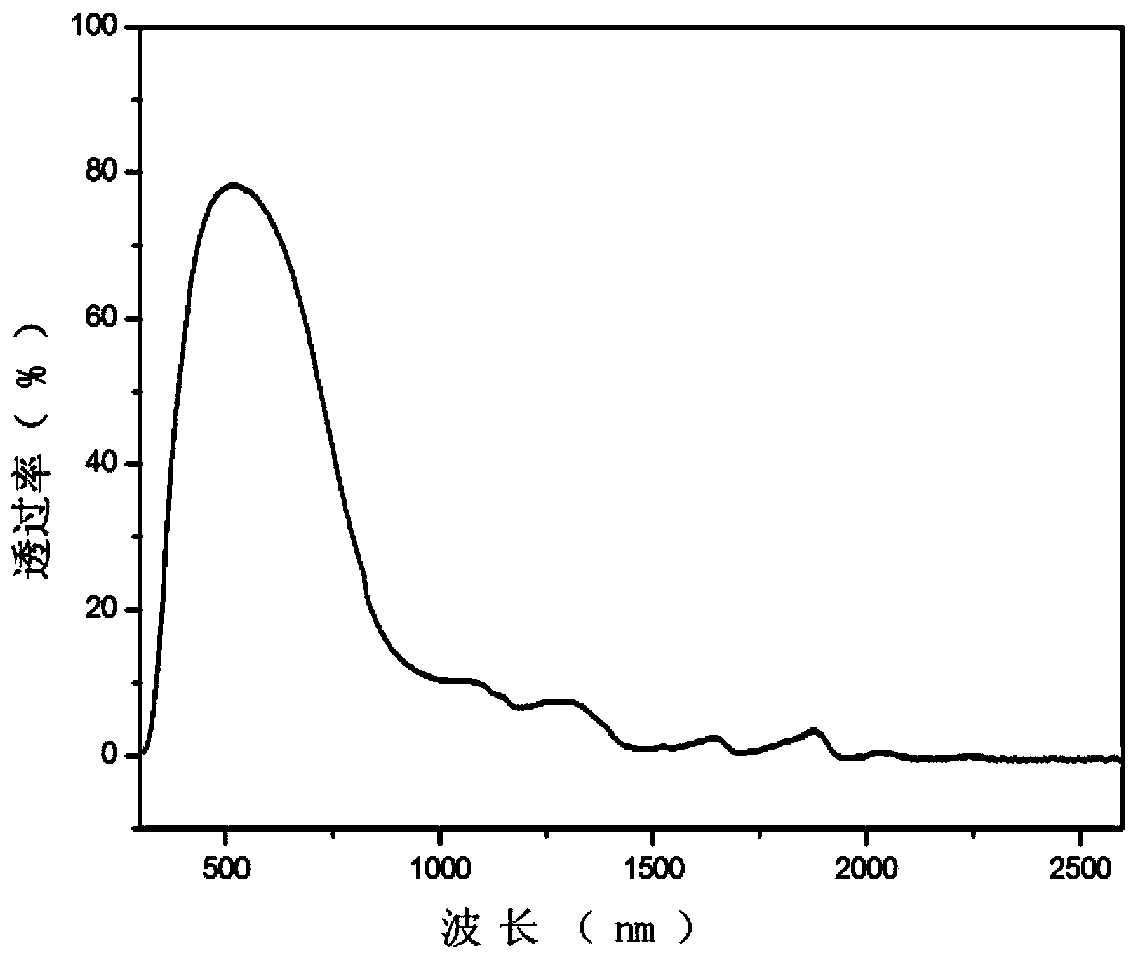

Embodiment 1

[0044] Soak 3 cm long, 3 cm wide, and 0.5 cm thick beech wood in 80° C. and 30 wt % hydrogen peroxide solution for 4 hours. The obtained delignified wood is cleaned with ethanol, and soaked in n-octadecyl mercaptan ethanol solution (concentration of n-octadecyl mercaptan 0.05mol / L) to react for 12h, and dried in a vacuum desiccator (vacuum drying The vacuum degree of the box is 200Pa, the drying temperature is 80°C, and the drying time is 20h). Immerse the delignified wood after hydrophobic, lipophilic and drying treatment in methyl methacrylate solution dispersed with 0.03wt% cesium tungstate nanoparticles (particle size: 10-50nm) and pressurize to 3MPa for 15min, then pump Vacuum to 80kPa and maintain for 2h and return to normal pressure. The obtained composite was heated and cured at 60° C. for 12 hours to finally obtain a transparent wood material with near-infrared shielding function, the content of inorganic particles with optical regulation function in the transparent ...

Embodiment 2

[0046] Willow with a length of 3 cm, a width of 3 cm and a thickness of 0.5 cm was soaked in a mixed solution of 5 wt % sodium hypochlorite and 20 wt % sodium hydroxide at 100 ° C for 5 h. The obtained delignified wood is cleaned with ethanol, and soaked in n-octadecyl mercaptan ethanol solution (concentration of n-octadecyl mercaptan 0.05mol / L) to react for 12h, and dried in a vacuum desiccator (vacuum drying The vacuum degree of the box is 200Pa, the drying temperature is 80°C, and the drying time is 20h). The delignified wood (delignified wood substrate) after hydrophobic, lipophilic and dry treatment is immersed in an epoxy resin solution (the monomer of which is bisphenol A glycidyl ether) was pressurized to 3MPa and kept for 15min, then vacuumed to 80kPa and kept for 2h and returned to normal pressure. The obtained composite was heated and cured at 60° C. for 12 hours to finally obtain a transparent wood material with an intelligent temperature regulation function. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com