Waste gas desulfurization system

A waste gas desulfurization and waste gas technology, applied in the direction of electrostatic effect separation, combined device, solid separation, etc., can solve the problems of troublesome pipe replacement, environmental protection, low efficiency, etc., and achieve the effects of convenient replacement and installation, improved efficiency, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

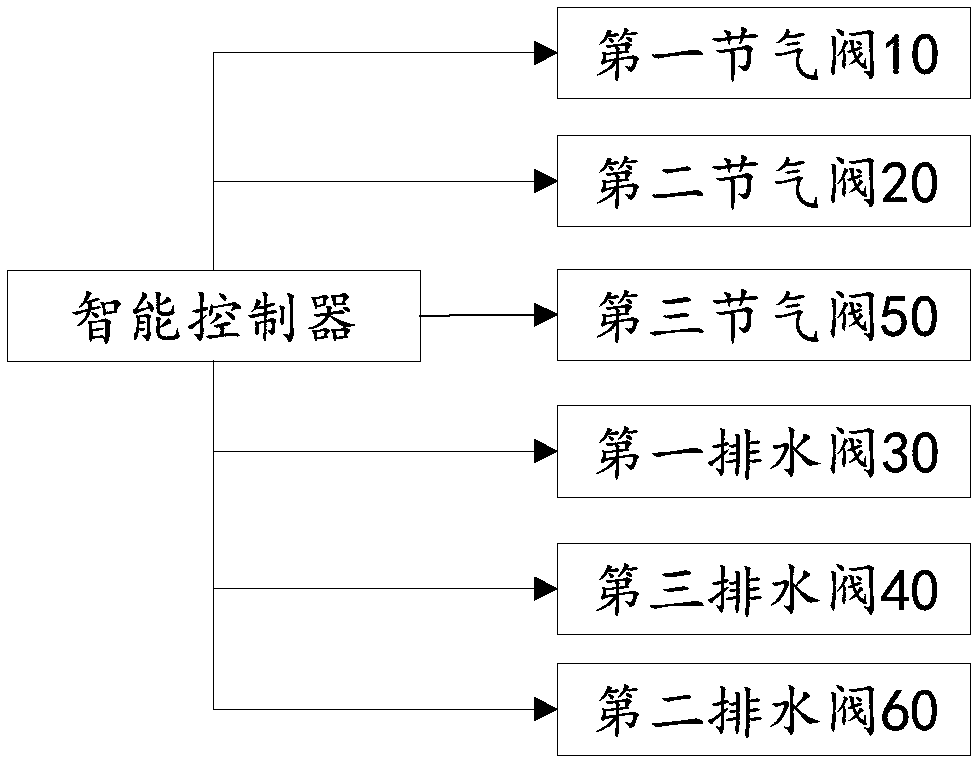

[0039] A desulfurization device, such as figure 1 As shown, the device includes a chimney 1 for discharging waste gas containing sulfide, and the chimney is communicated with an integral series heat exchanger 2 through a first damper 10, and the heat exchanger 2 is communicated with a desulfurization tower In order to pass the cooled waste gas into the dust removal chamber 3 in the desulfurization tower, the heat exchanger 2 and the dust removal chamber 3 can be communicated through a second damper 20;

[0040] The desulfurization tower is respectively provided with a dust removal chamber 3, an atomization spray chamber 4, a sulfide absorption chamber 5, and a waste water collection chamber 6 from top to bottom, and the dust removal chamber 3, atomization spray chamber 4, and sulfide absorption chamber 5 and the waste water collection chamber 6 are connected successively, and the waste water collection chamber 6 is communicated with the circulating water device; the waste wate...

Embodiment 2

[0055] A desulfurization device, such as figure 1 As shown, the device includes a chimney 1 for discharging waste gas containing sulfide, and the chimney is communicated with an integral series heat exchanger 2 through a first damper 10, and the heat exchanger 2 is communicated with a desulfurization tower In order to pass the cooled waste gas into the dust removal chamber 3 in the desulfurization tower, the heat exchanger 2 and the dust removal chamber 3 can be communicated through a second damper 20;

[0056] The desulfurization tower is respectively provided with a dust removal chamber 3, an atomization spray chamber 4, a sulfide absorption chamber 5, and a waste water collection chamber 6 from top to bottom, and the dust removal chamber 3, atomization spray chamber 4, and sulfide absorption chamber 5 and the waste water collection chamber 6 are connected successively, and the waste water collection chamber 6 is communicated with the circulating water device; the waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com