Analysis method for measuring manganese, silicon and potassium in graphene oxide

An analysis method, the technology of manganese in ene, is applied in the field of quantitative analysis of impurity elements in graphene oxide, and achieves the effects of fast measurement, wide application range and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

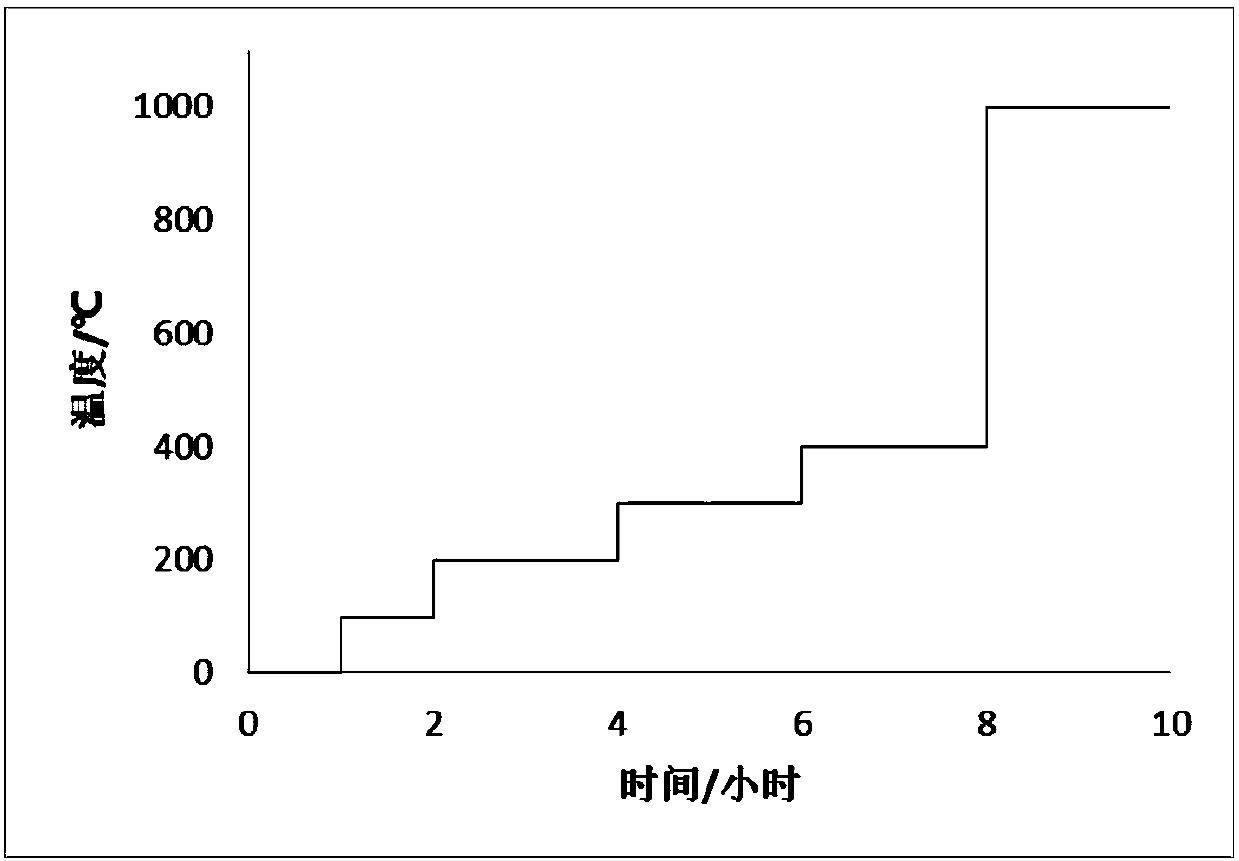

Method used

Image

Examples

Embodiment 1

[0084] Graphene oxide prepared by the Hummers method is used as a sample to measure manganese, silicon and potassium content in graphene oxide, and an inductively coupled plasma spectrometer is used. The working conditions and analysis lines of the instrument are as follows: analysis lines: Mn 257.610nm, Si251.611nm, K 766.468nm;

[0085] 2. Table 1 Instrument working conditions

[0086] project

parameters

project

parameters

High frequency, MHz

40.68

Incident power, kW

0.9

Entrance slit, μm

20

Sheath gas flow, L / min

0.2

Auxiliary air flow L / min

0.3

Sample lifting volume, mL / min

1.2

Integration time, s

2

one point

Reflected power, W

<10

-

-

[0087] (1), the reagents used in the determination process are as follows:

[0088] (1.1), hydrochloric acid: ρ1.19g / mL, prepared by high-purity or sub-boiling distillation;

[0089] (1.2), nitric acid...

Embodiment 2

[0140] Graphene oxide prepared by the Hummers method was used as a sample to measure the contents of manganese, silicon and potassium in the graphene oxide. The working conditions of the instrument and the analysis line were as in Example 1.

[0141] (1), the reagent used in the assay process is consistent with Example 1;

[0142] (2), sampling and sample preparation are consistent with embodiment 1;

[0143] (3), sample dissolution test is consistent with embodiment 1;

[0144] (4), coexistence element interference test is consistent with embodiment 1;

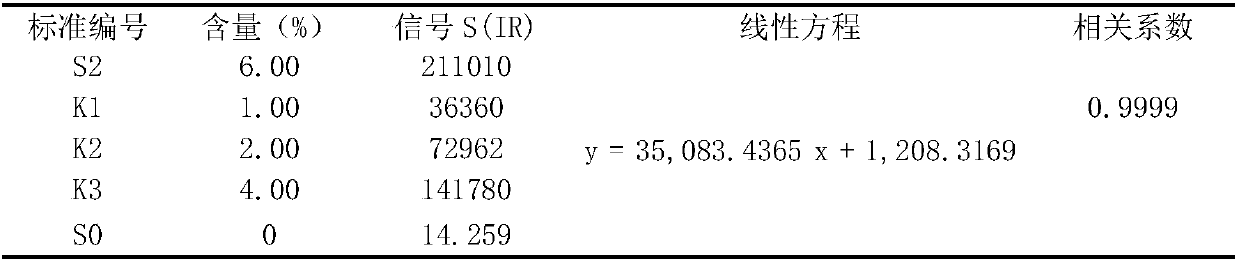

[0145] (5), working curve linearity test

[0146] Pipette 8.00mg of Mn, 0.50mg of Si, and 0.20mg of K into a 100mL volumetric flask, add 10mL of hydrochloric acid and 5 drops of hydrofluoric acid, dilute to the mark with water, and shake well. This mixed standard solution contains 8.00% Mn, 0.50% Si, 0.20% K, which is the highest point in the standard curve.

[0147] Pipette 6.00mg of Mn, 0.30mg of Si, and 0.10mg of K int...

Embodiment 3

[0165] Graphene oxide prepared by the Hummers method was used as a sample to measure the contents of manganese, silicon and potassium in the graphene oxide. The working conditions of the instrument and the analysis line were as in Example 1.

[0166] (1), the reagent used in the assay process is consistent with Example 1;

[0167] (2), sampling and sample preparation are consistent with embodiment 1;

[0168] (3), sample dissolution test is consistent with embodiment 1;

[0169] (4), coexistence element interference test is consistent with embodiment 1;

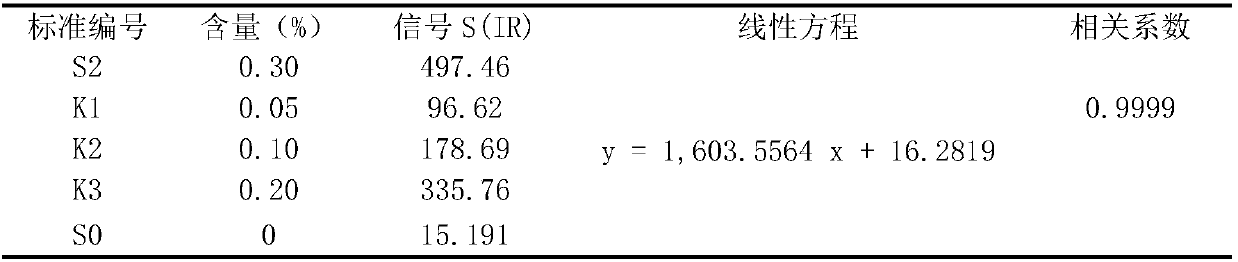

[0170] (5), working curve linearity test

[0171] Pipette 8.00mg of Mn, 0.50mg of Si, and 0.20mg of K into a 100mL volumetric flask, add 10mL of hydrochloric acid and 5 drops of hydrofluoric acid, dilute to the mark with water, and shake well. This mixed standard solution contains 8.00% Mn, 0.50% Si, 0.20% K, which is the highest point in the standard curve.

[0172] Pipette 6.00mg of Mn, 0.30mg of Si, and 0.10mg of K int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com