Gear speed reducer capable of achieving flexible impact

A gear reduction and gear technology, applied in the field of transmission mechanism, can solve the problems of not being suitable for small machines or vehicles, increasing structural complexity, and generating large impacts, etc., and achieves the effects of simple structure, low manufacturing cost, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

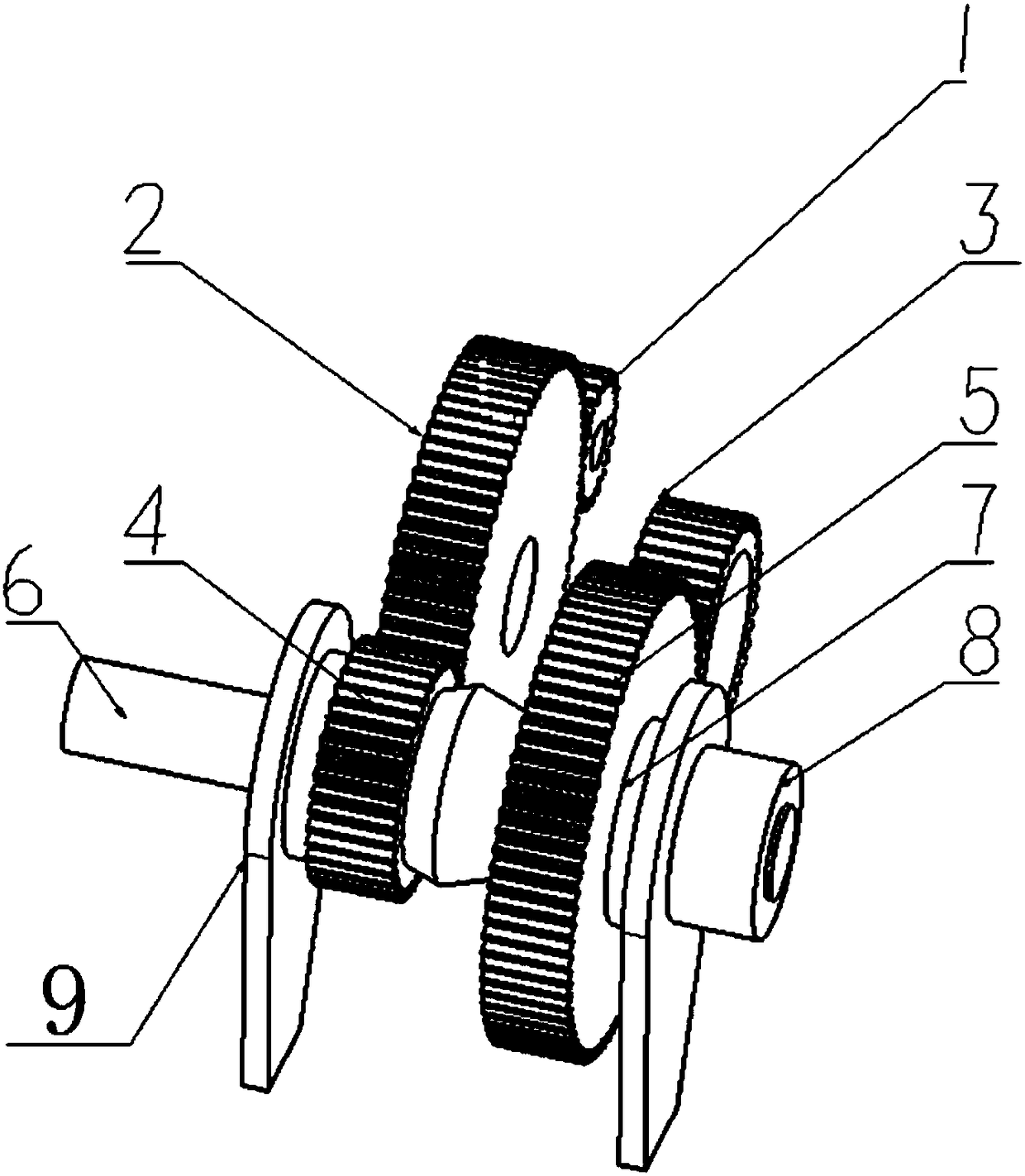

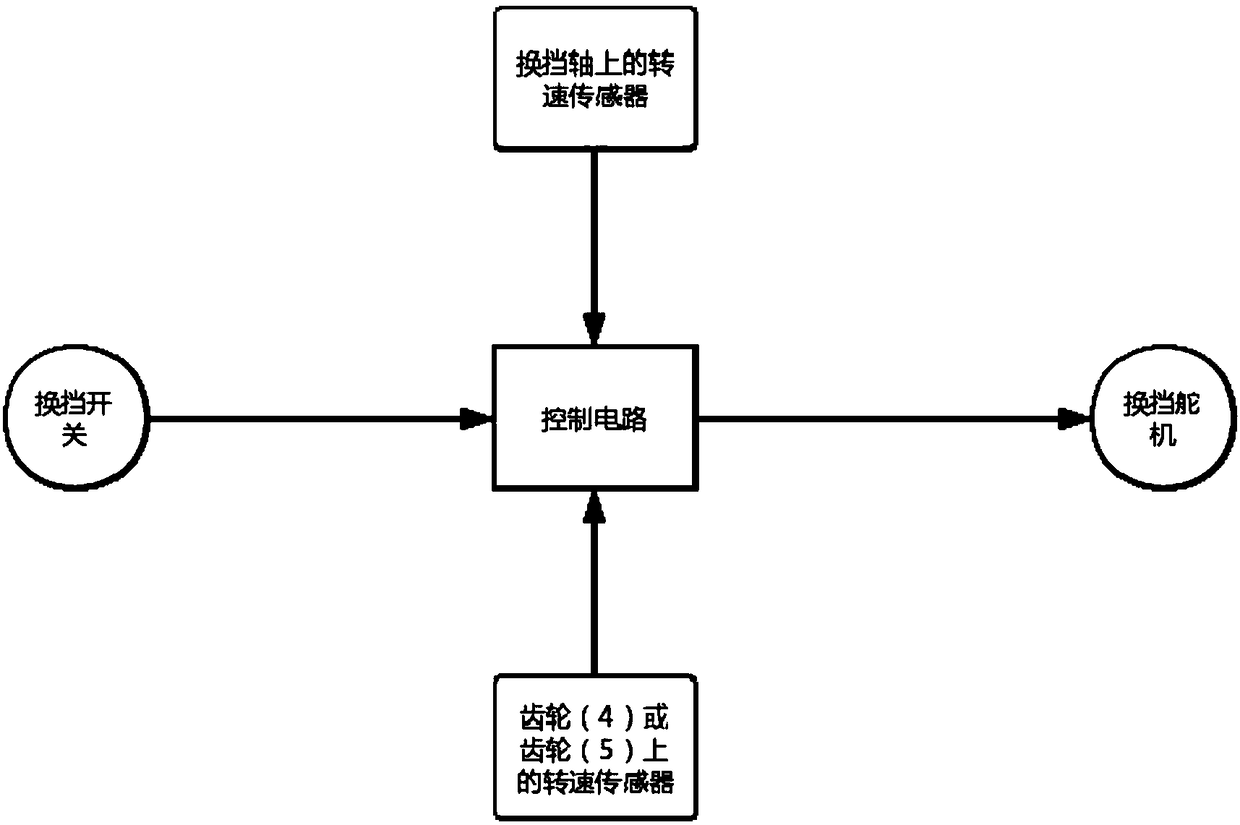

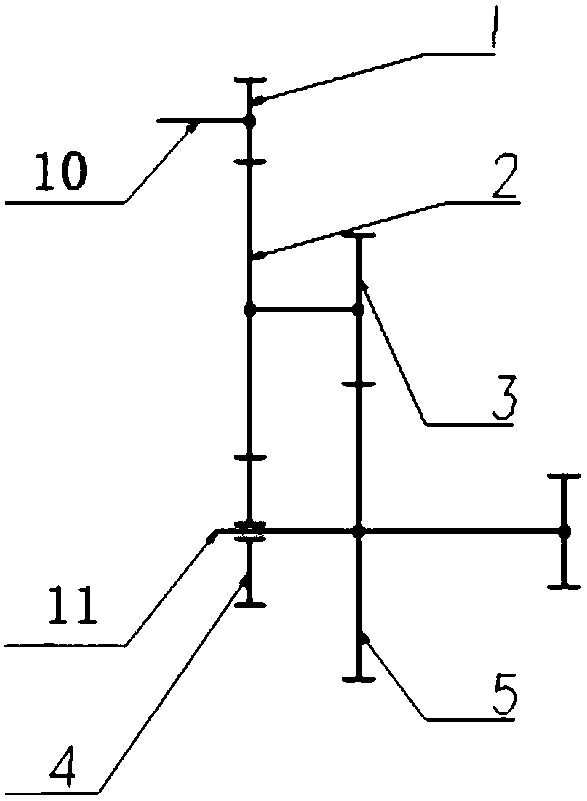

[0024] see figure 1 , Figure 3 to Figure 5 , a gear reduction device for realizing flexible impact, including a shift shaft 6 connected to two frames 9, the shift shaft 6 is located between the two frames 9 and is symmetrically provided with two tapered surfaces, And the side with the larger area of the two conical surfaces is close together, and the third constant meshing gear 4 and the fourth constant meshing gear 5 are respectively arranged on the two conical surfaces, and the outer side of the conical surface and the fourth constant meshing gear The inner sides of the third constant meshing gear 4 and the fourth constant meshing gear 5 are provided with friction material coatings, and the third constant meshing gear 4 and the fourth constant meshing gear 5 are connected to the frame 9 on the corresponding side through the support flange 7 , The third constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com