Multifunctional hydraulic cleaning filter car

A multi-functional, hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem of data analysis of hydraulic oil pollutants, no solution to replenish oil, and filter accuracy is not higher. High-level problems, to achieve the effect of being conducive to maintenance, fault diagnosis, and strong on-site adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

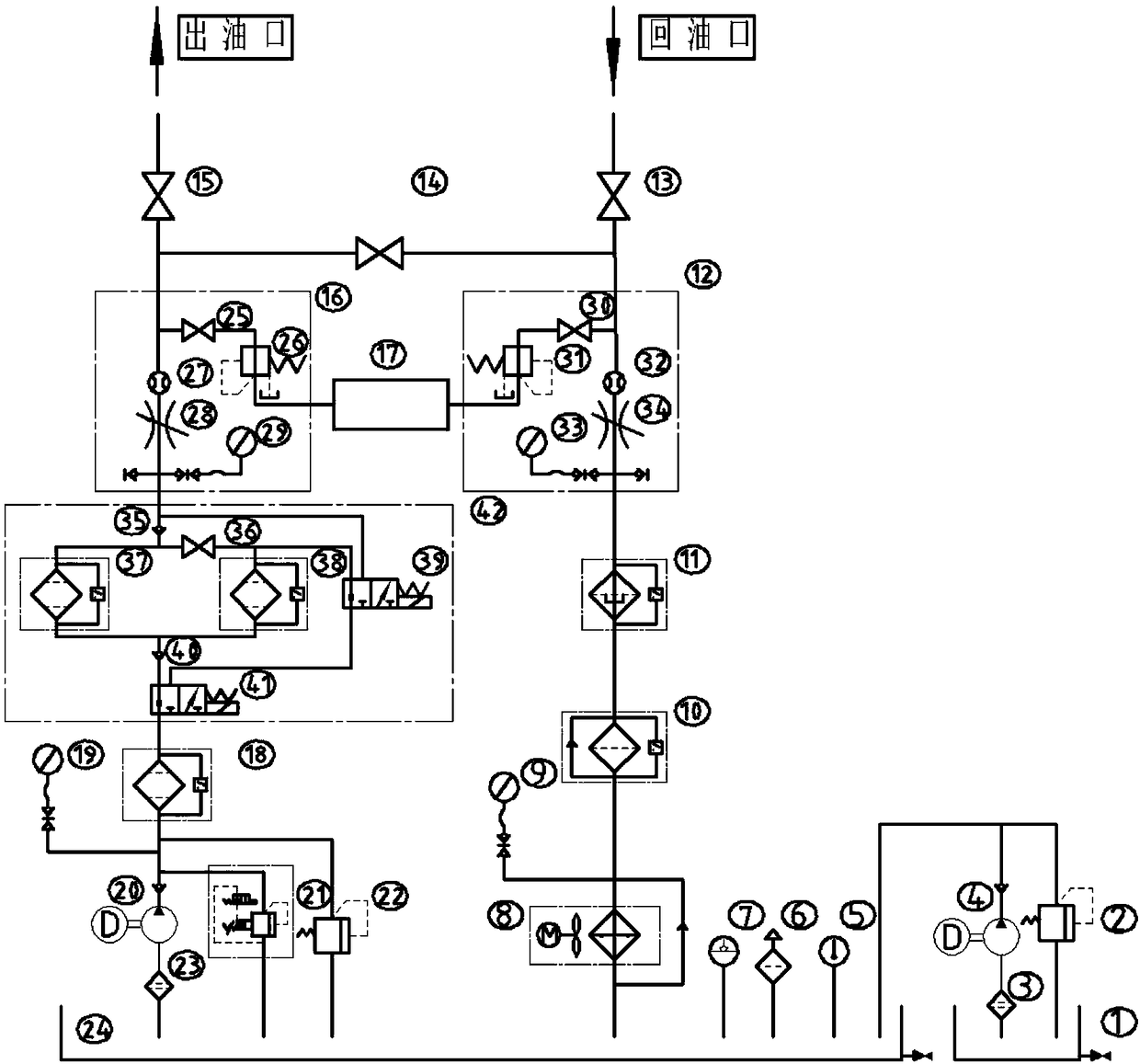

[0020] Such as figure 1 Shown, a kind of multifunctional hydraulic cleaning filter car, car body is prior art, so do not describe in detail, also do not show among the figure. The system structure and working principle of the multifunctional hydraulic cleaning filter car are as follows:

[0021] (1) Oil return filter cleaning process

[0022] Connect the oil return port of the oil return joint with the hydraulic system that needs to be filtered. The oil passes through the oil return stop valve 13, and then successively passes through the oil return flow meter 32, the oil return throttle valve 34, the oil return pressure gauge 1 33, and the magnetic return valve. Filter 11, coarse filter 10, return oil pressure gauge two 9, radiator 8 enter main oil tank 24. The flow adjustment of the return flow process is realized by adjusting the oil return throttle valve 34 , and is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com