Oxidant mixed injection system and an operation method for underground coal gasification

An underground gasification and injection system technology, applied in coal gasification, underground mining, construction, etc., can solve the problem of limited operating temperature range in the selection and design of underground equipment, increased equipment transportation costs and delivery time, and the gasification process is not fully reached. problems such as optimal conditions, to achieve the effect of reducing size and cost, reducing material selection restrictions, and improving stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

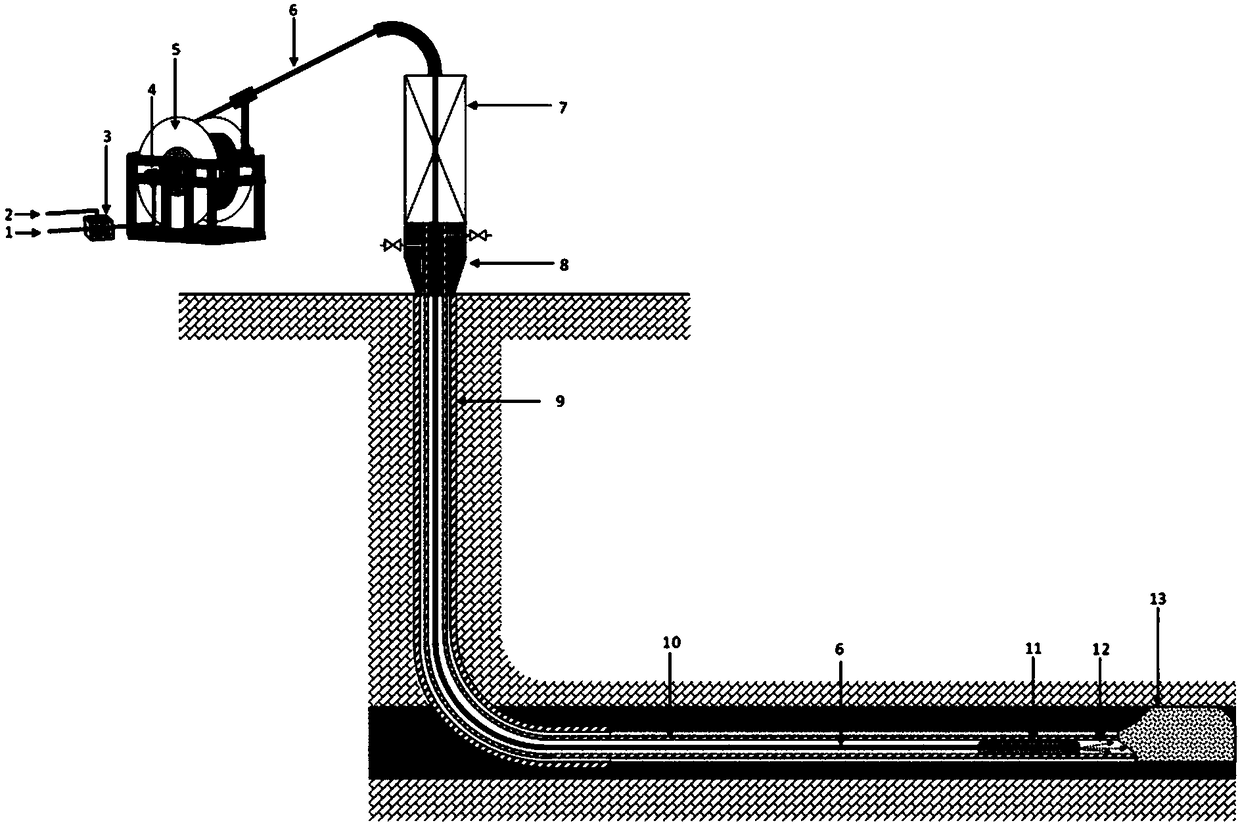

[0028] The invention provides an oxidant mixing injection system and an operation method for an underground coal gasification process. Specifically, the present invention provides an injection system for mixing oxidant and water in a controllable ratio in an underground coal gasification process, and also provides the application of this oxidant mixed injection system in an underground coal gasification process. The operation method, specifically, can be used in the normal operation process of the underground coal gasification process.

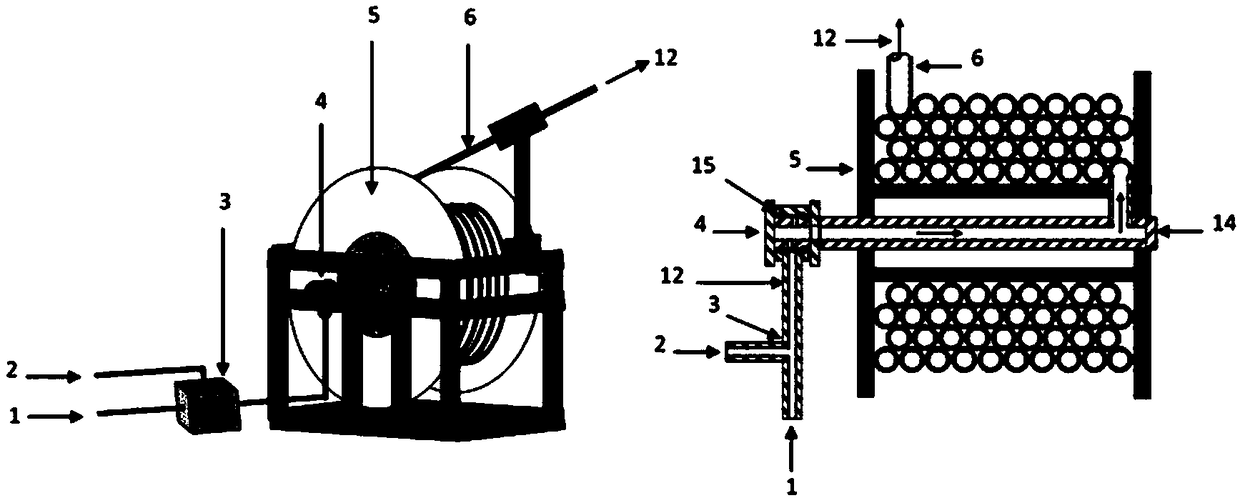

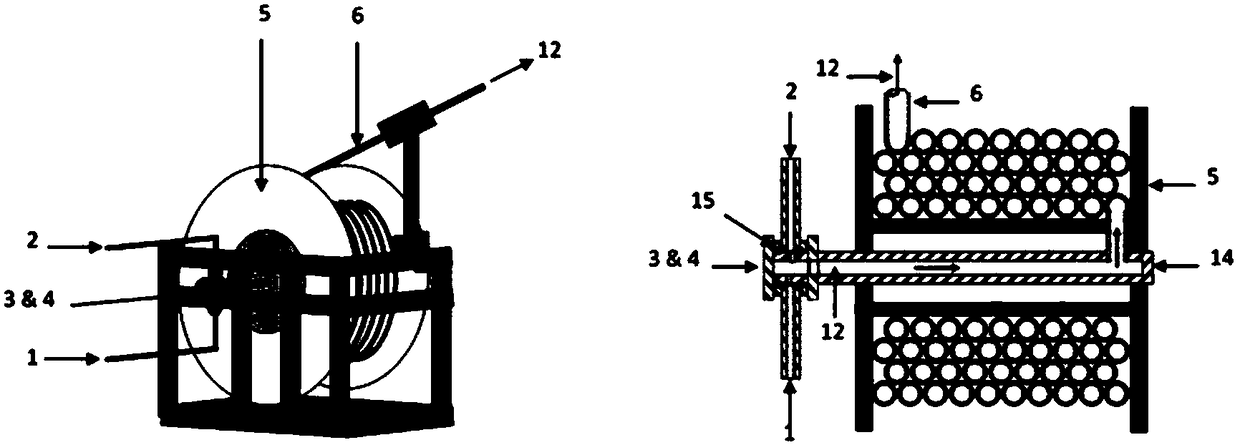

[0029] The invention provides an oxidant mixing injection system for an underground coal gasification process, which includes:

[0030] 1) Two-phase mixing equipment, located upstream of the rotary joint of the coiled tubing reel, is used to uniformly mix the oxidant and water at the surface.

[0031] 2) Rotary joint, located downstream of the two-phase mixing equipment, connects the two-phase flow with the coiled tubing string through the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com