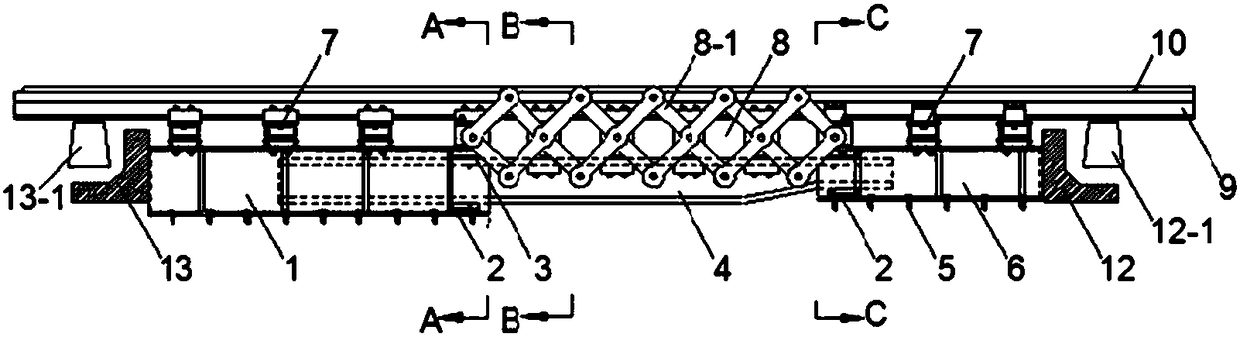

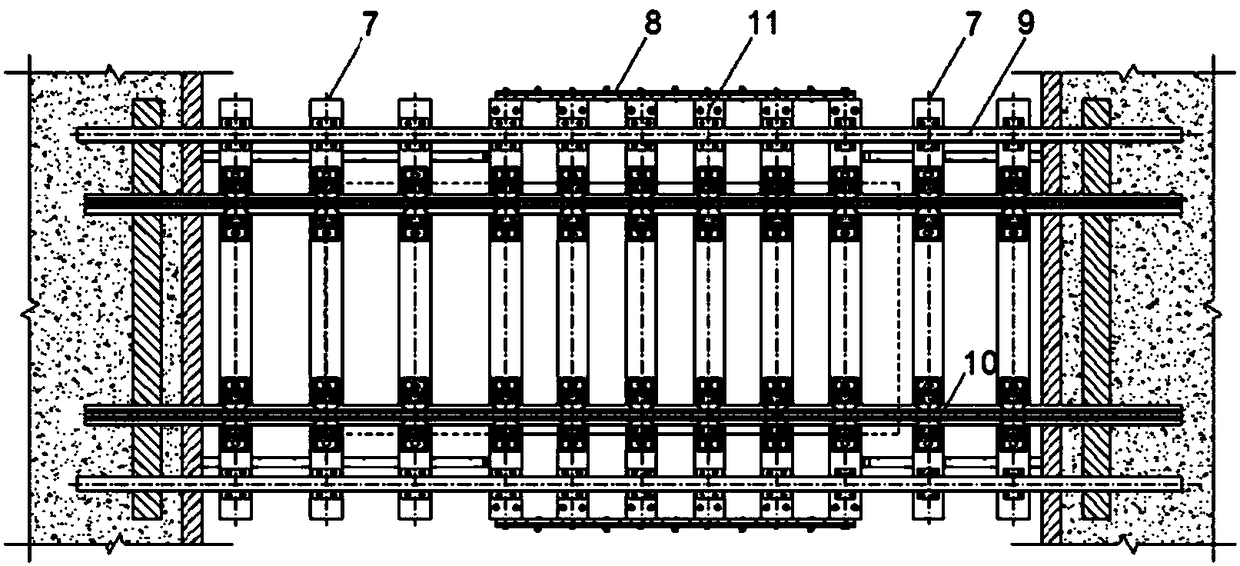

Integral beam-end retractable device suitable for super-long-span railway steel bridge

A telescopic device, integral technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of skewed movable steel sleepers, cracked or broken connecting rods, difficult error control, etc., and achieves high vertical stiffness and good integrity. , the effect of reducing the design workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

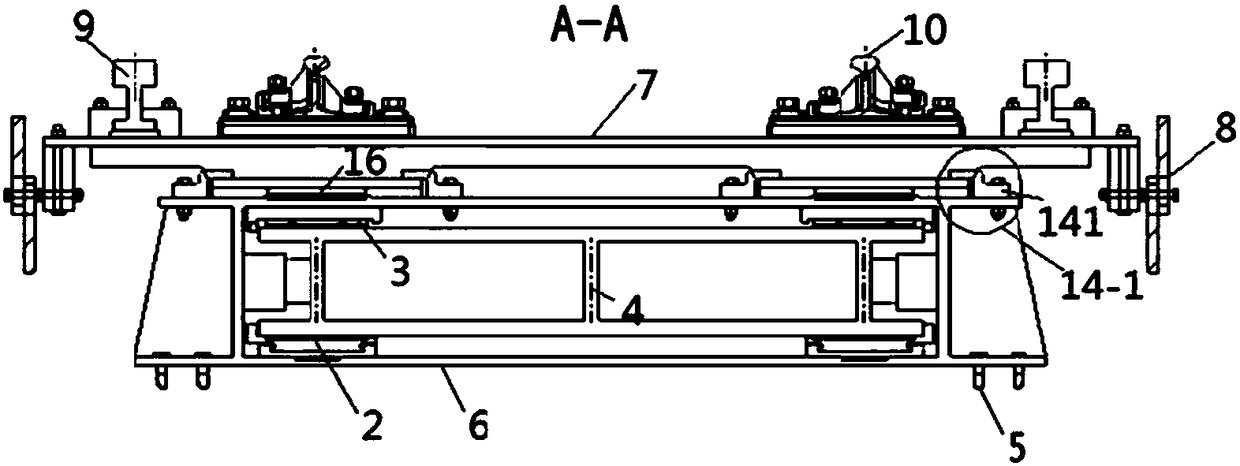

[0044] refer to Figure 3a~3c and Figures 5a-5c , the fixed steel sleeper 7 on the movable end displacement box 1 is fixedly connected with the movable end displacement box 1 through the first fixed steel sleeper connection gusset 141 to realize the synchronization of displacement. Such as Figure 5a As shown, a gap may be provided between the first fixed steel sleeper connecting buckle plate 141 and the vertical contact surface (at F) of the fixed steel sleeper 7, the gap is determined according to the lateral displacement of the main bridge end, and the gap is filled with Materials with high modulus of elasticity. The fixed steel sleeper connects the buckle plate and the movable end displacement box, and the fixed steel sleeper 7 on the fixed end displacement box 6 is connected with the fixed end displacement box 6 through the second fixed steel sleeper connection buckle plate 142, wherein as Figure 5c As shown, there is a gap between the second fixed steel sleeper conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com