Method for preparing medicine intermediate for treating osteoarthritis

A technology of hydroxyapatite and zinc salt, which is applied in the field of preparation of drug intermediates for the treatment of osteoarthritis, can solve problems such as harsh reaction conditions, achieve the effects of optimizing the catalytic system, overcoming heavy metal wastewater, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of zinc salt modified hydroxyapatite supported cerium ammonium nitrate catalyst:

[0039] First with Ca(NO 3 ) 2 .4H 2 O and diammonium hydrogen phosphate as raw materials, Zn(NO 3 ) 2 .6H 2 O is a modifier, and the zinc salt-modified hydroxyapatite is prepared by chemical precipitation under alkaline conditions; then the zinc salt is prepared by ion exchange between the zinc salt-modified hydroxyapatite and cerium ammonium nitrate in ethanol aqueous solution Modified hydroxyapatite supported cerium ammonium nitrate catalyst.

[0040] Concrete preparation process is as follows:

[0041] (A) Preparation of zinc salt modified hydroxyapatite:

[0042] A-1) 10mmol Ca(NO 3 ) 2 .4H2 O and 7mmol Zn(NO 3 ) 2 .6H 2 O was dissolved in 50ml of water, then added dropwise to 100ml of ammonia solution with pH=11 and stirred evenly to obtain a calcium-zinc mixed solution;

[0043] A-2) Add 50 ml of diammonium hydrogen phosphate aqueous solution (containing 10 ...

Embodiment 2

[0052] The Zn / Ce / HAP / X prepared by the present invention is used as a catalyst, and its catalytic performance to methyl 6-hydroxyhexanoate is investigated to generate methyl 6-oxohexanoate. The catalytic process is as follows:

[0053] Add 10mmol methyl 6-hydroxyhexanoate and catalyst (0.15g, ~10%wt) to 20ml ethanol in a parallel synthesizer, then add 30%wt hydrogen peroxide solution (containing 20mmol hydrogen peroxide, 2.0eq), 20-30 Stir the reaction at ℃ (i.e. reaction at room temperature), detect the catalytic effect of different catalysts by GC-MS, and count the reaction status of the reaction solution after the reaction, including the time taken for the reaction to reach equilibrium, the conversion rate of methyl 6-hydroxyhexanoate and the target product The selectivity of methyl 6-carbonylhexanoate, the results are shown in table 1:

[0054] Table 1 Catalytic effects of different catalysts

[0055] catalyst

[0056] The above results show that the catalytic a...

Embodiment 3

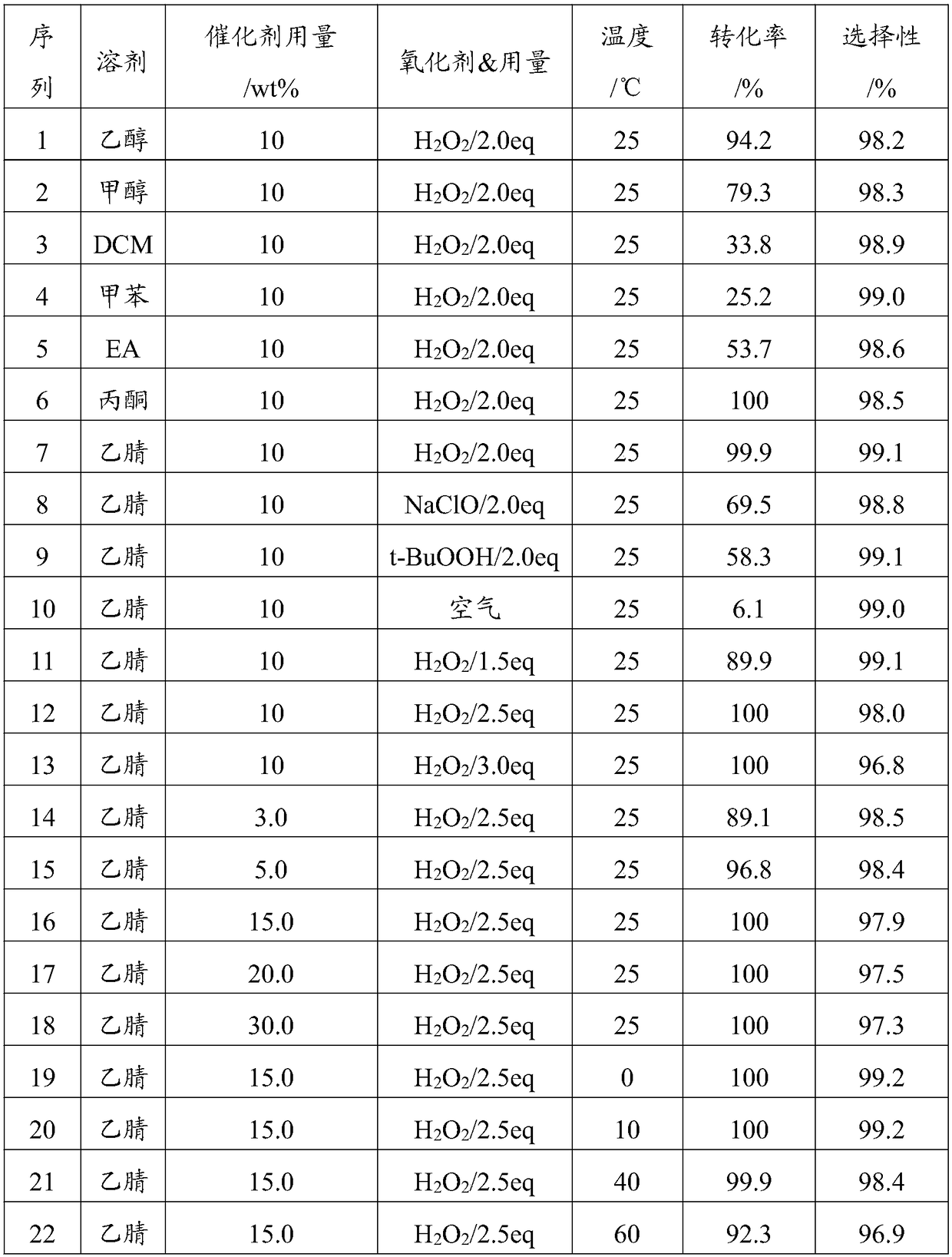

[0058] When determining Zn / Ce / HAP / 400 as the catalyst, the reaction solvent, temperature, catalyst dosage, oxidant and its oxidant dosage were further optimized:

[0059] In the parallel synthesizer, 10mmol 6-hydroxyhexanoic acid methyl ester, catalyst Zn / Ce / HAP / 400 (44mg-440mg, 3.0~30%wt) are added in the 20ml solvent, then add oxidizing agent (molar dosage is substrate 6- 1.5-3.0eq of methyl hydroxyhexanoate), stirring reaction at 0-60°C, GC-MS detection of the catalytic effect of different catalysts, statistics of the reaction of the reaction solution after the end of the reaction, including the time used for the reaction to reach equilibrium, 6- The selectivity of methyl hydroxycaproate conversion and target product 6-oxomethylhexanoate, the results are shown in table 2:

[0060] Table 2 List of catalytic system optimization results

[0061]

[0062] Note: DCM refers to dichloromethane; EA refers to ethyl acetate; H 2 o 2 30%wt hydrogen peroxide solution; NaClO is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com