Preparation method of photocatalyst formaldehyde-removal blanket

A technology of photocatalyst and cotton felt, applied in the field of felting of cotton felt, can solve problems such as formaldehyde pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

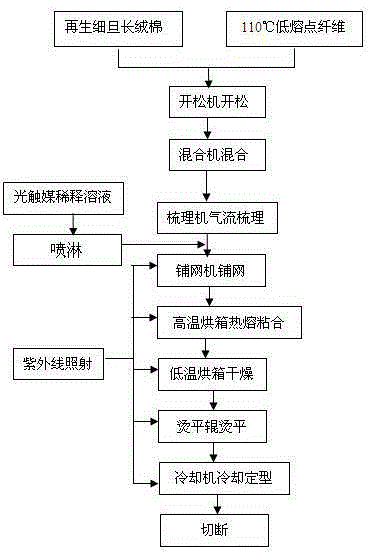

[0020] The present invention first prepares raw materials and configures photocatalytic dilution solution, then refits traditional felting equipment, sprays photocatalytic dilution solution on the cotton net during the felting process, and uses ultraviolet light to illuminate at the same time, so that formaldehyde process is eliminated. The specific process is as follows:

[0021] see figure 1 , Considering the sound absorption and cost of the cotton felt, the present invention selects regenerated fine-denier long-staple cotton and 110°C low-melting fiber as raw materials in the present invention, and the 110°C low-melting fiber selects fiber with a sheath-core structure. The weight ratio of regenerated fine-denier long-staple cotton to 110°C low-melting fiber is 3:1.

[0022] When selecting raw materials, configure photocatalyst dilution solution: first select titanium concentrate with high titanium dioxide content as raw material, add molten ore agent, after firing and aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com