Preparation method and application of nut oil micro-emulsion spray

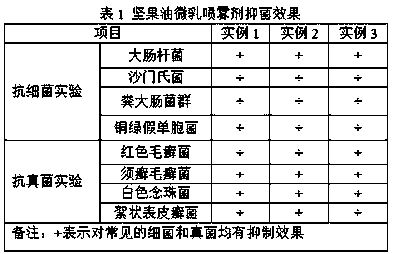

A technology of microemulsion spray and argan oil, which is applied in aerosol delivery, anti-inflammatory agents, pharmaceutical formulations, etc., can solve the problem that macadamia nut oil and green bark extract cannot be miscible and used together, the by-products of green bark cannot be effectively utilized, Argan oil is easy to oxidize and other problems, to achieve the effect of increasing economic added value, simple preparation method, and overcoming easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 adopts the following steps to realize the present invention:

[0024] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (1:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (8 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenize through a high-pressure micro-fluidic homogenizer (homogenization pressure 50MPa) for 3 times until a transparent and clear nano-emulsion is formed;

[0025] (2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 100 mesh and 8 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, a...

Embodiment 2

[0027] Embodiment 2 adopts the following steps to realize the present invention:

[0028] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (1:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (10 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenized by a high-pressure micro-fluidic homogenizer (homogenization pressure 60MPa) 4 times until a transparent and clear nano-emulsion is formed;

[0029] (2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 100 mesh and 6 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, and extr...

Embodiment 3

[0031] Embodiment 3 Adopt the following steps to realize the present invention:

[0032] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (2:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (12 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenized by a high-pressure micro-jet homogenizer (homogeneous pressure 80MPa) for 3 to 5 times until a transparent and clear nano-emulsion is formed;

[0033](2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 200 mesh and 10 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, and ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com