Superlow-temperature lithium ion battery electrolyte and lithium ion battery using same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as inability to work effectively, and achieve the effect of high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

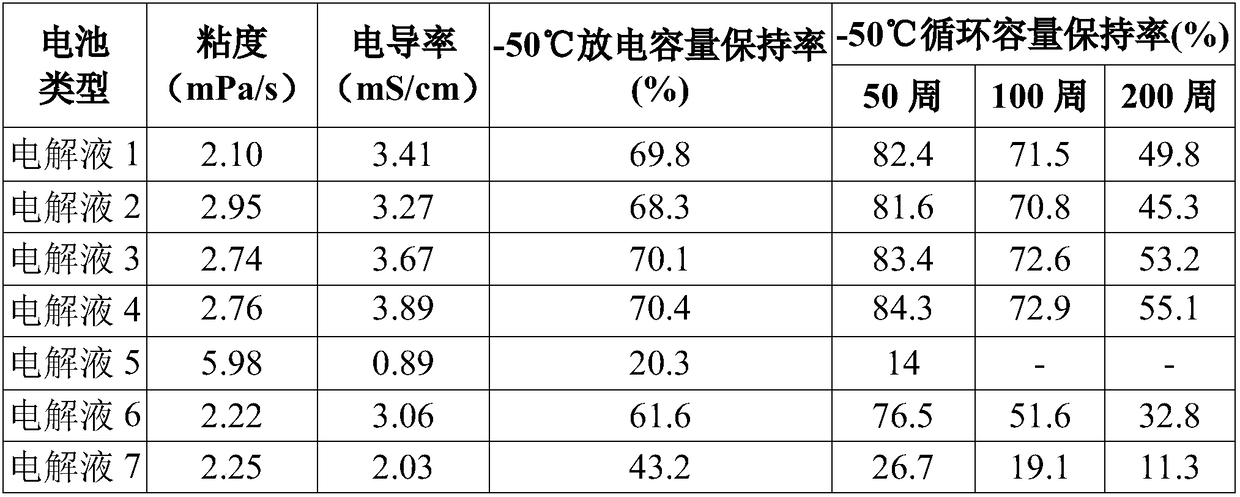

Examples

Embodiment 1

[0021] Preparation of Electrolyte 1 and Experimental Battery 1

[0022] (1) Preparation of positive electrode sheet

[0023] Mix the positive electrode active material NMC111 positive electrode material, the conductive agent acetylene black, and the binder polytetrafluoroethylene according to the mass ratio of lithium iron phosphate: acetylene black: polytetrafluoroethylene = 8:2:2, add N-methylpyrrolidone, Thoroughly stir and mix to form a uniform positive electrode slurry, which is uniformly coated on a 15-micron thick aluminum foil, and dried to obtain a positive electrode sheet.

[0024] (2) Negative sheet preparation

[0025] Negative electrode active material artificial graphite negative electrode material, conductive agent acetylene black, binder styrene-butadiene rubber, thickener sodium carboxymethyl cellulose according to mass ratio artificial graphite: acetylene black: styrene-butadiene rubber: thickener = 90:4 :4:2 for mixing, adding deionized water, fully stirri...

Embodiment 2

[0031] Preparation of Electrolyte 2 and Experimental Cell 2.

[0032] The difference from Example 1 is: carbon disulfide (CS 2 ), ethyl butyrate (EB), diglyme (DGM), N, N-dimethylformamide (DMFA) according to the mass ratio CS 2 : EB: DGM: DMFA = 20:40:20:20 to mix evenly.

Embodiment 3

[0034] Preparation of Electrolyte 3 and Experimental Cell 3.

[0035] The difference from Example 1 is that in the preparation process of the electrolyte, 1% of lithium difluorophosphate and 1% of vinylene carbonate are added after the lithium salt is completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com