Contact system structure of vacuum arc extinguishing chamber

A vacuum interrupter and contact system technology, applied in the field of power components, can solve the problems of large loop resistance, lengthened coil structure, long bounce time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

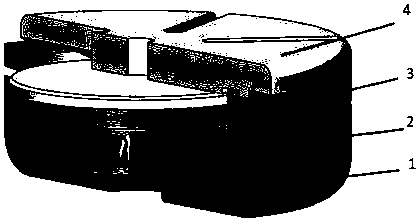

[0016] Example. A vacuum interrupter contact system structure, such as Figure 1 to Figure 3 As shown, it includes a contact system 1, the contact system 1 is provided with an inner contact 2, and the upper part of the contact system 1 is provided with a main contact 4; the lower part of the main contact 4 is connected with a hook ring 3, and the inner contact 2 It is connected with the main contact 4 through the hook ring 3 .

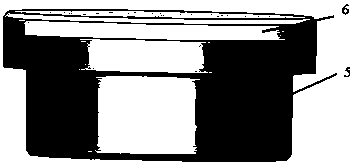

[0017] The inner contact 2 includes an oxygen-free copper part 5 and a diffused copper part 6, and the diffused copper part 6 is arranged above the oxygen-free copper part 5; the diffused copper part 6 in the inner contact 2 is made of alumina or zirconia Made of dispersed copper material; the section of the inner contact 2 is a "T"-shaped structure, the section of the hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com