Prediction method of plastic deformation mode for multi-pass cold drawing of pure aluminum conductor based on ANSYS/LS-DYNA

A prediction method and technology of plastic deformation, applied in geometric CAD, design optimization/simulation, instruments, etc., can solve the problem of lack of accurate understanding of pure aluminum wire, and achieve the effect of improving drawing process and improving fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be specifically introduced and illustrated below in conjunction with the accompanying drawings. The present invention provides an efficient and accurate prediction method for the multi-pass cold drawing plastic deformation mode of industrial pure aluminum conductors based on ANSYS / LS-dyna, specifically The content is as follows:

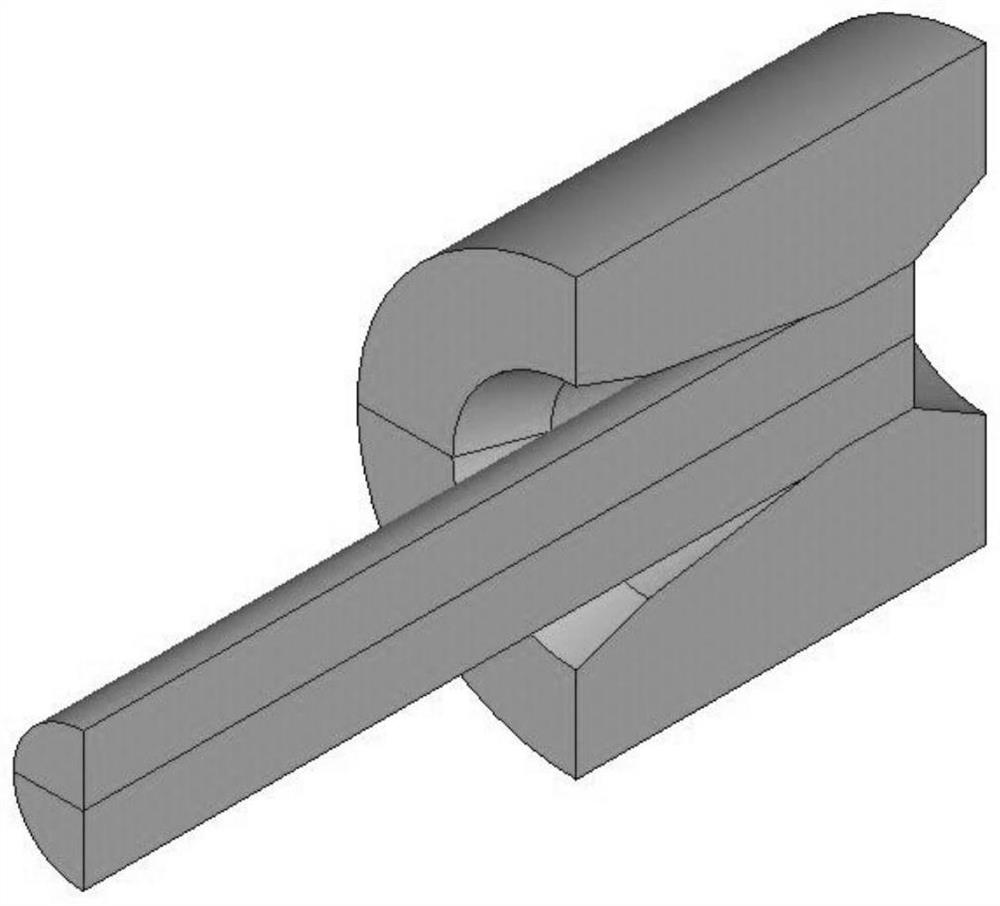

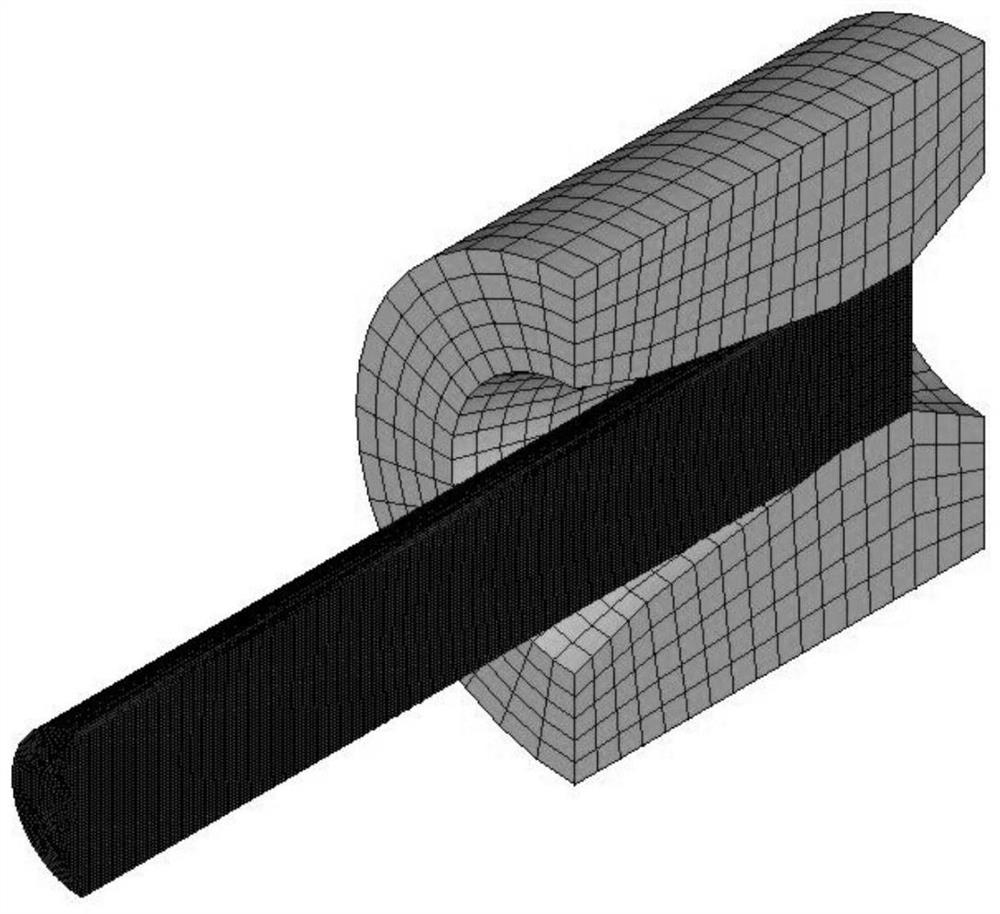

[0031] 1. According to the process parameters of pure aluminum wire and mold, the finite element model of wire and mold is established based on ANSYS parametric modeling technology

[0032] Before modeling, first select the unit type, use the ANSYS parametric language command ET to define the unit type, and select the unit type of the mold and wire as SOLID164. Such as figure 1 As shown, after the unit type is selected, the modeling of the three-dimensional simulation analysis model is carried out, and the specific process is as follows: a two-dimensional model of the longitudinal section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com