A mask transfer pre-alignment device and method

A pre-alignment and mask technology, applied in the field of mask transmission, can solve the problem of low pre-alignment accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

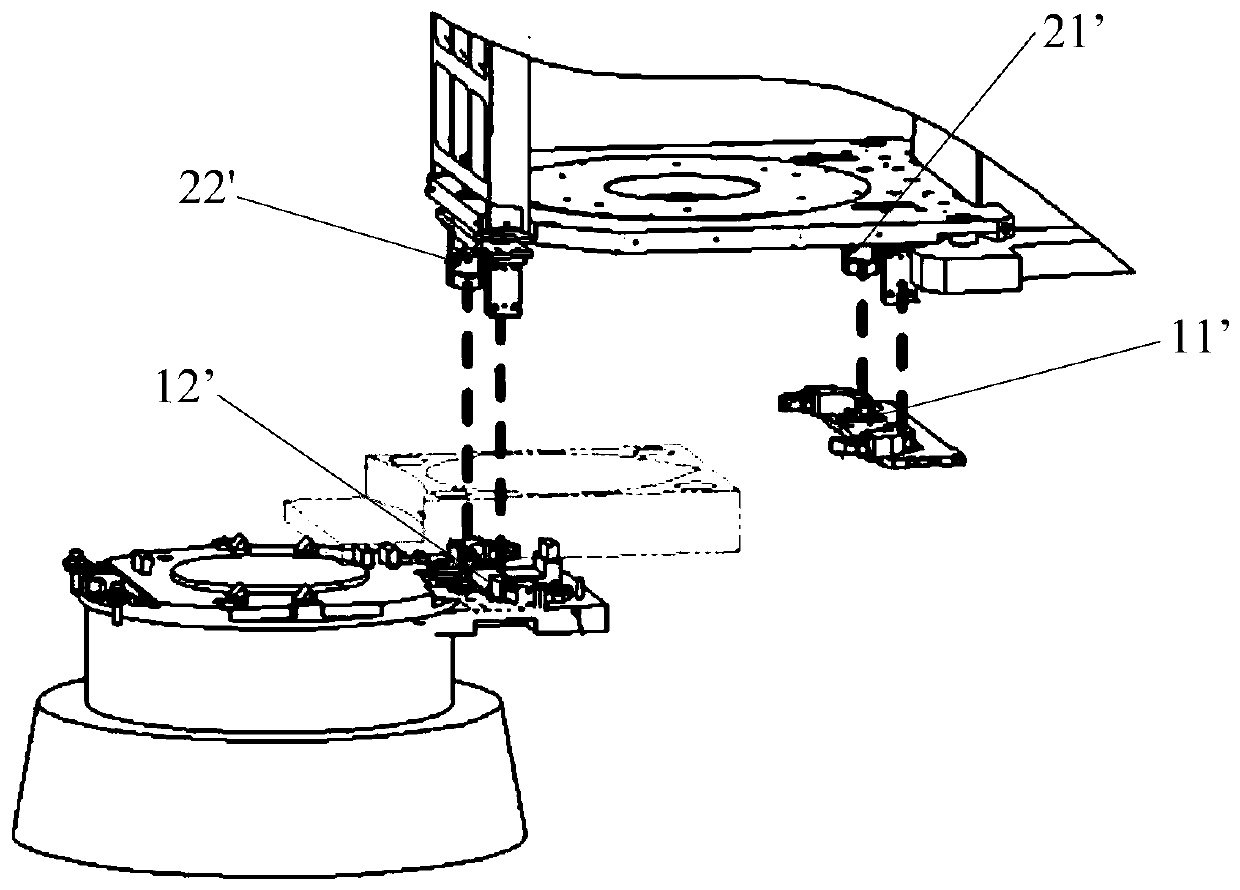

[0057] Such as Figure 4 and Figure 5 As shown, the present invention provides a mask transmission pre-alignment device, which sequentially includes a light source module 100, a pre-alignment test component 200 and an imaging module 300;

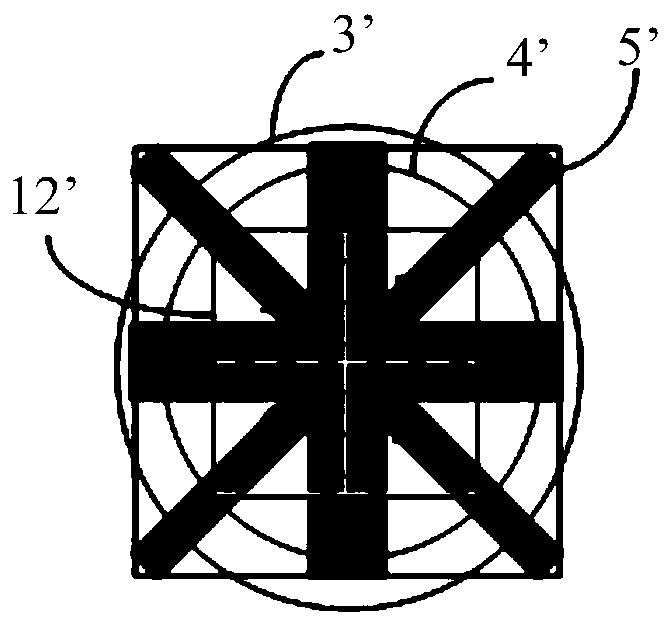

[0058] The light source module 100 sequentially includes a light source 1, a collimation unit 2, and a reticle 3 with a cross mark 31; the light source 1, the collimation unit 2, and the reticle 3 with a cross mark 31 are coaxially arranged, and the positions of the three are opposite to each other. fixed, and installed on the reference plate of the pre-alignment device, the preferred light source 1 is an LED light source that emits LED light, and the collimation unit 2 is an illumination lens that collimates the LED light emitted by the light source 1, with a cross mark The reticle 3 is used to provide components for self-adjusting compensation patterns, and the cross mark 31 therein is opaque. The pre-alignment test part 200 is a reticle ...

Embodiment 2

[0075] Such as Figure 8 As shown, different from Embodiment 1, a second turning prism 8 is also provided between the semi-transparent and semi-reflecting prism 5 and the four-quadrant detector 7 in the present embodiment. At this time, the light source 1, the illumination lens, The reticle 3 with the cross mark 31, the pre-alignment test component 200, the first turning prism 4, the semi-transparent and half-reflecting prism 5, the CCD detector 6, the four-quadrant detector 7 and the second turning prism 8 form a second double far In the imaging system, the light emitted by the light source 1 sequentially passes through the illumination lens, the reticle 3 with the cross mark 31, the pre-alignment test part 200, the first turning prism 4, the semi-transparent and half-reflecting prism 5 and the second turning prism 8, and then enters the The four-quadrant detector 7 performs imaging.

[0076] In summary, the mask transmission pre-alignment device provided by the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com