Evaporator steam conveying pipe heat preservation device for biological pharmacy

A technology for biopharmaceuticals and pipelines, which is applied in pipeline protection, heat preservation, and pipeline protection through heat insulation. It can solve problems such as performance degradation, poor hydrophobicity, and poor heat preservation conditions, and achieve the goal of improving heat preservation effects and pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

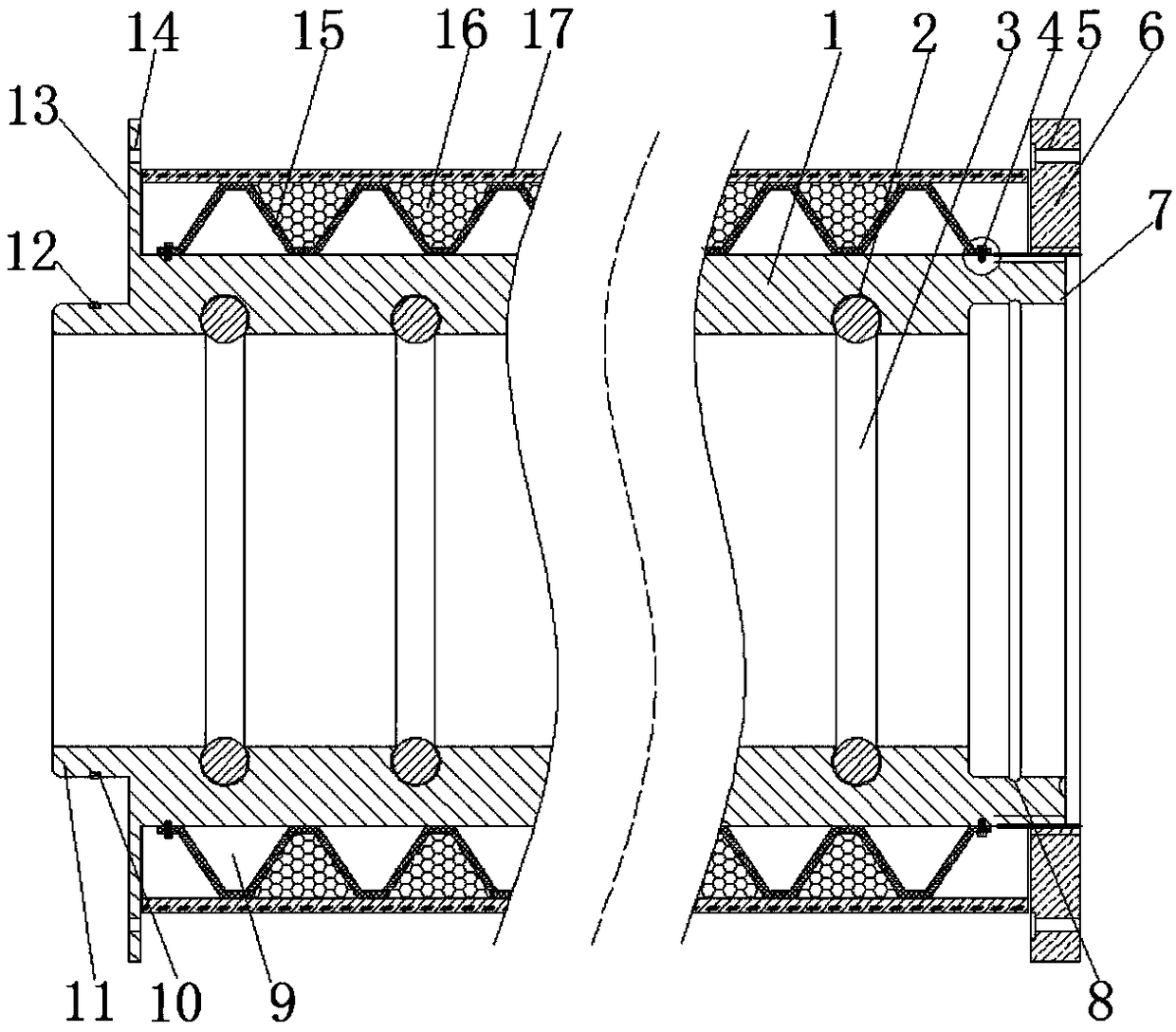

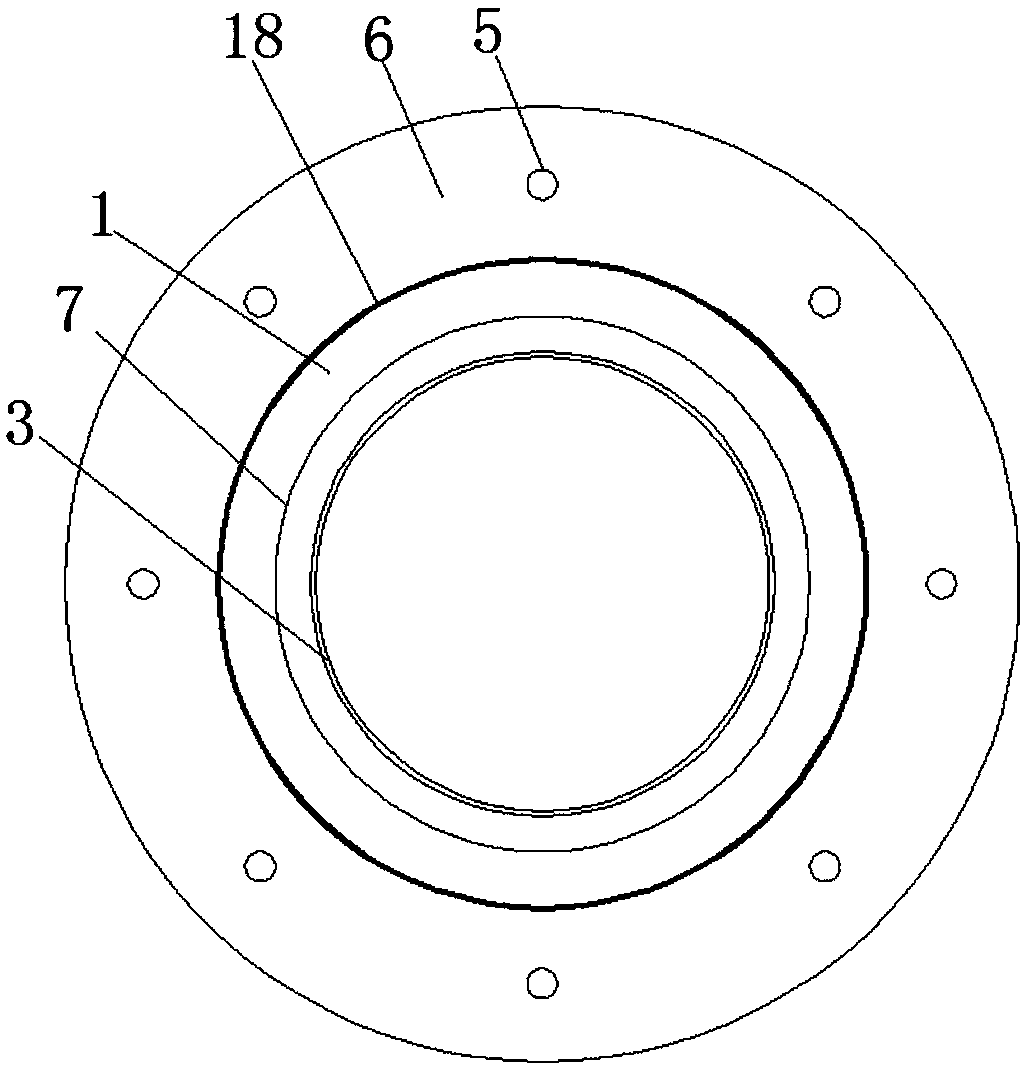

[0022] refer to Figure 1-3 , a thermal insulation device for steam delivery pipelines for evaporators used in biopharmaceuticals, comprising a sleeve body 1 made of rubber material with good ductility, and the transverse depth of the annular shoulder 7 is greater than that of the annular convex tube 11, which is convenient for two sleeves The main body 1 is butted, and the longitudinal depth of the annular shoulder 7 is equal to the wall thickness of the annular convex tube 11, the cross section of the rubber ring 3 is circular, and the cross section of the rubber ring groove is a semicircle including the center of the circle, and the bellows Between the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com