Preparation method of humic acid suspended liquid fertilizer

A liquid fertilizer, humic acid technology, applied in the preparation of organic fertilizers, liquid fertilizers, nitrate fertilizers, etc., can solve the problems of poor stability of suspended fertilizers, poor adhesion of crop leaves, and low content, and achieve fluidity. The effect of improving and reducing affinity and improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

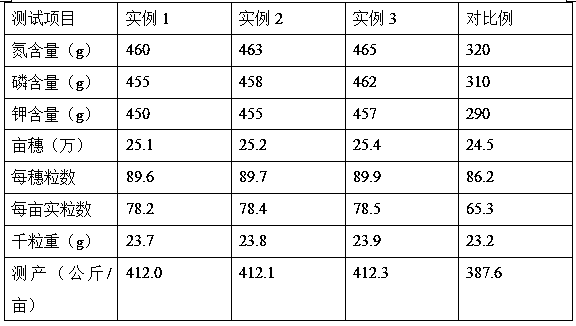

Examples

Embodiment Construction

[0024]Take the sweet potato starch wastewater from the starch factory and the secondary sedimentation activated sludge and mix them according to the mass ratio of 5:1 to obtain the suspended sludge. After adjusting the pH of the suspended sludge to 9.8-10.2 with a sodium hydroxide solution with a mass fraction of 15%, Place it in a high-pressure steam pot for 50-60 minutes, control the temperature of the high-pressure steam pot to 120-150 ° C, and the pressure to 4-5 MPa, and naturally cool to room temperature to obtain a lysed suspension; place the lysed suspension in a high-speed refrigerated centrifuge , centrifuge at -20~-15°C for 5~8min at 6000~7000r / min, remove the lower precipitate to obtain the upper layer, adjust the pH of the upper layer to 4~5 with a sulfuric acid solution with a mass fraction of 40%, and let it stand Precipitate for 12-18 hours, collect the supernatant to obtain the lysate; adjust the pH of the lysate to 2-3 with hydrochloric acid with a mass fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com