Laser welding automatic following protective gas jetting blowing system

A protective gas and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting welding quality, inability to melt effectively, and poor adjustment accuracy, so as to improve the effectiveness of blowing and improve the accuracy The effect of sex and maintenance effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

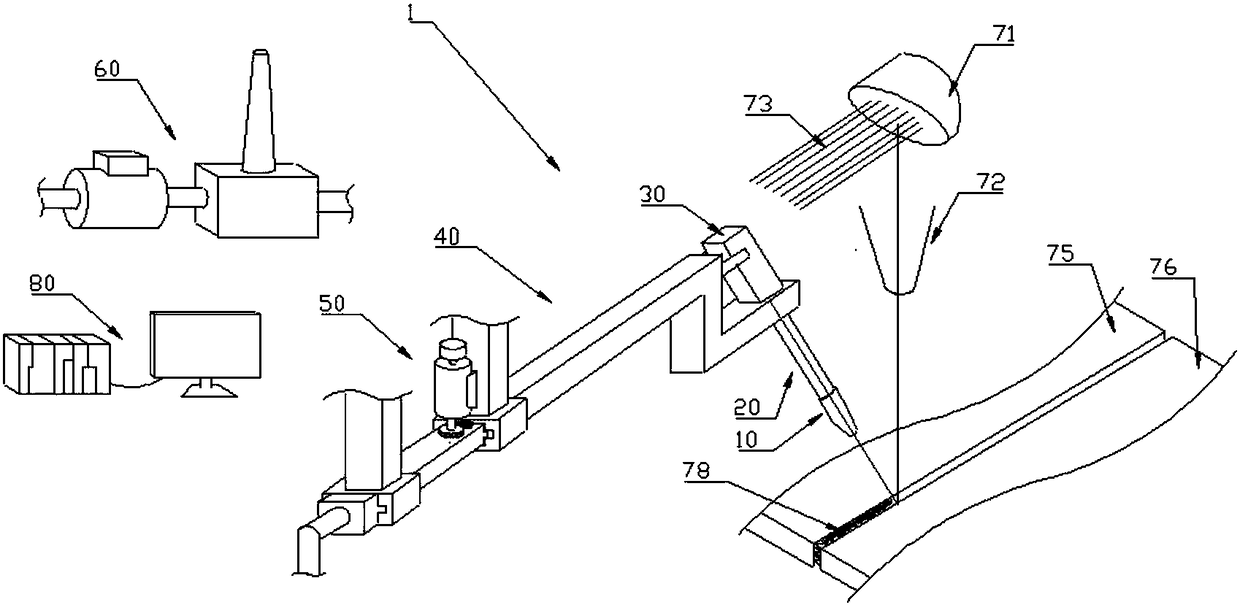

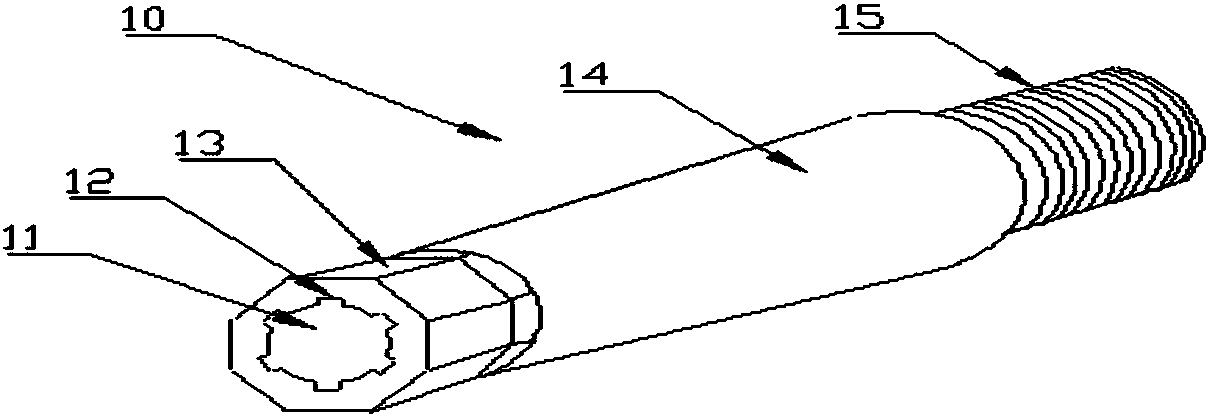

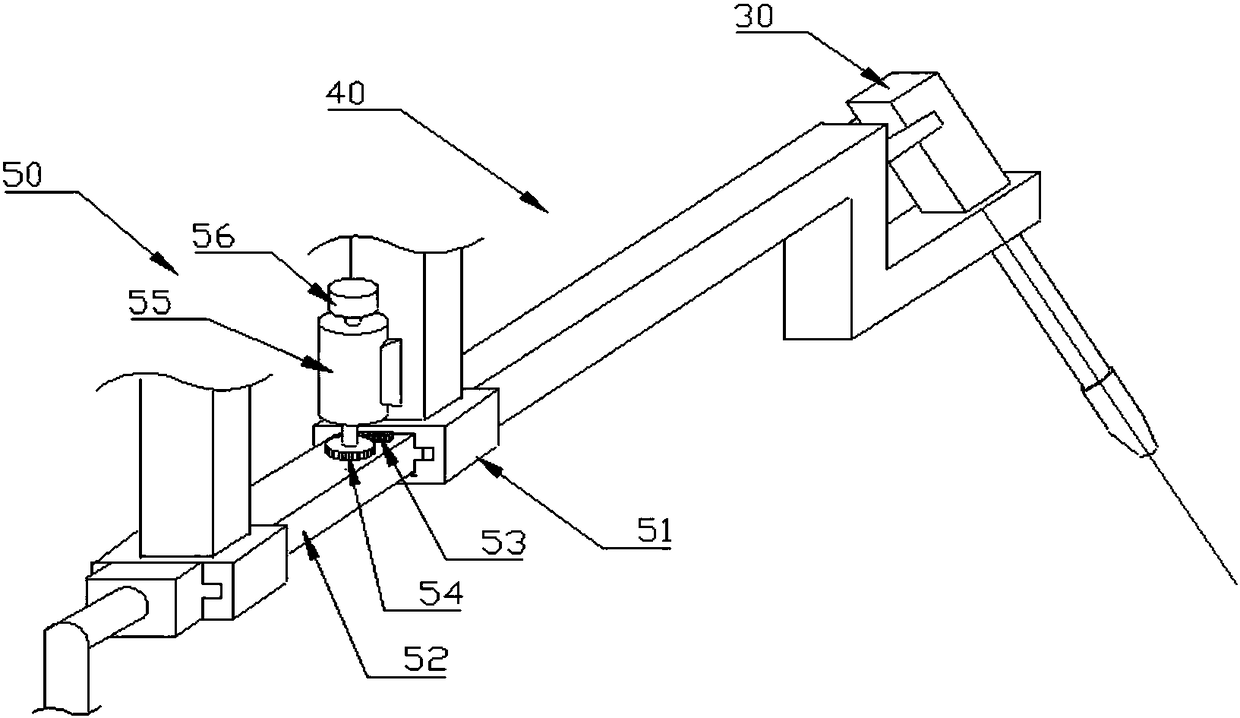

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and specific examples.

[0023] The invention provides a system device for laser welding self-following protective gas injection, which is improved in terms of equipment component structure and control mode. The gas is injected from the spray rod and the nozzle, and the actual position of the welding seam sprayed by the protective gas is accurately indicated. It is displayed on the CRT screen through the position detection system and the coordinated control components. The image analysis software calculates and judges whether the position of the protective gas injection is The middle position of the welding seam is the laser focus position. If the measured deviation exceeds the range, it can automatically follow the focus position for adjustment and correction; the flow and pressure detection control part detects whether the sprayed protective gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com