Capped tundish bottom permeable ring and tundish slag tapping control method using capped tundish bottom permeable ring

A technology of tundish and cover, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of increasing the difficulty of manual operation control, large temperature drop of molten steel, and long blowing time of large volume, so as to achieve suppression The effect of slag entering the crystallizer, eliminating confluence vortex, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

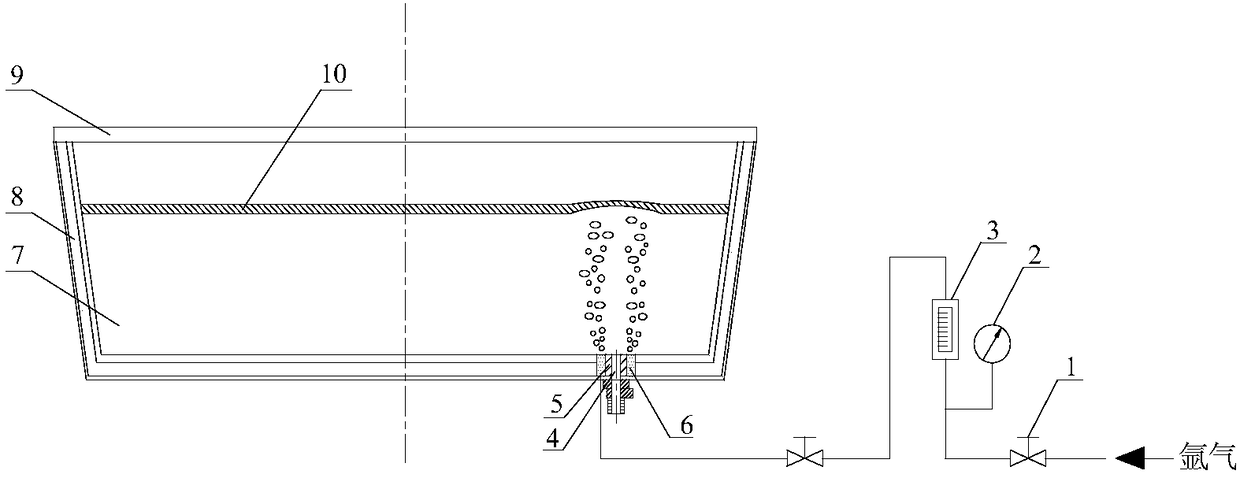

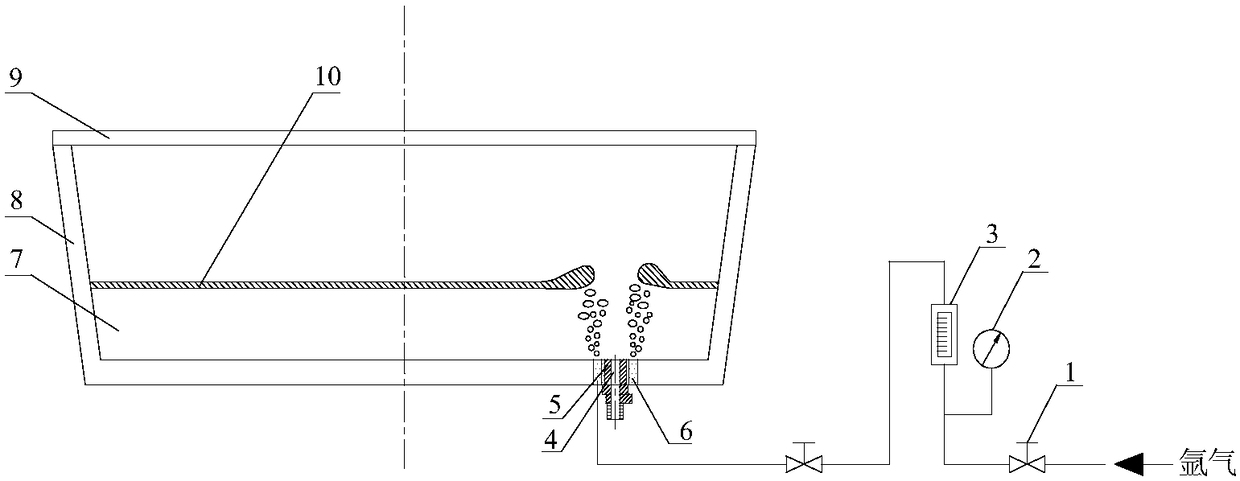

[0031] The tundish used in this embodiment is 25 tons.

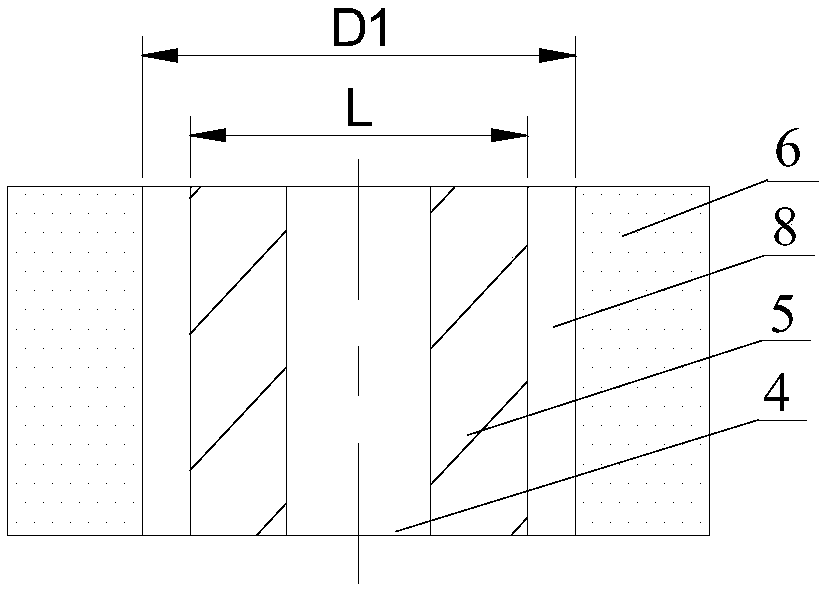

[0032] A ventilating ring at the bottom of a tundish with a cover, which is arranged around a tundish nozzle block (5); the ventilating ring (6) is a cylindrical structure; ) maximum cross-sectional span≤the internal diameter of the upper end face ring≤2 times the maximum cross-sectional span of the tundish nozzle block (5), the height of the breathable ring (6)=tundish bottom height.

[0033] The tundish nozzle block (5) is cylindrical, with a maximum cross-sectional span of 300mm, and the inner diameter D1 of the upper end surface of the breathable ring (6) is 450mm.

[0034] The air-permeable ring (6) on the upper end surface of the air-permeable ring at the bottom of the tundish with a cover has a width of 20 mm.

[0035] The above-mentioned method of controlling slag by using the breathable ring at the bottom of the tundish with a cover specifically includes the following steps:

[0036] Step 1: Connect the breath...

Embodiment 2

[0041] The tundish used in this embodiment is 35 tons.

[0042]A ventilating ring at the bottom of a tundish with a cover, which is arranged around a tundish nozzle block (5); the ventilating ring (6) is a cylindrical structure; ) of the maximum section span≤the inner diameter of the upper end ring≤2 times the maximum section span of the tundish nozzle seat brick (5), the height of the breathable ring (6)=the height of the bottom of the tundish.

[0043] The tundish nozzle seat brick (5) is cube-shaped with a maximum cross-sectional span of 300 mm, and the inner diameter D1 of the upper end surface of the breathable ring (6) is 480 mm.

[0044] The air-permeable ring (6) on the upper end surface of the air-permeable ring at the bottom of the tundish with a cover has a width of 50 mm.

[0045] The above-mentioned method of controlling slag by using the breathable ring at the bottom of the tundish with a cover specifically includes the following steps:

[0046] Step 1: Connect...

Embodiment 3

[0051] The tundish used in this embodiment is 45 tons.

[0052] A ventilating ring at the bottom of a tundish with a cover, which is arranged around a tundish nozzle block (5); the ventilating ring (6) is a cylindrical structure; ) of the maximum section span≤the inner diameter of the upper end ring≤2 times the maximum section span of the tundish nozzle seat brick (5), the height of the breathable ring (6)=the height of the bottom of the tundish.

[0053] The tundish nozzle seat brick (5) is cube-shaped, with a maximum cross-sectional span of 350mm, and the inner diameter D1 of the upper end surface of the breathable ring (6) is 550mm.

[0054] The air-permeable ring (6) on the upper end surface of the air-permeable ring at the bottom of the tundish with a cover has a width of 150 mm.

[0055] The above-mentioned method of controlling slag by using the breathable ring at the bottom of the tundish with a cover specifically includes the following steps:

[0056] Step 1: Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com