Lead paste for negative electrode of lead-carbon battery, preparation method of lead paste, polar plate for negative electrode of lead-carbon battery, and lead-carbon battery

A technology of lead-carbon battery and negative electrode paste, applied in the field of lead-carbon battery negative plate and lead-carbon battery, lead-carbon battery negative electrode paste, can solve problems such as excessive hydrogen evolution, achieve low production cost, improve utilization rate, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

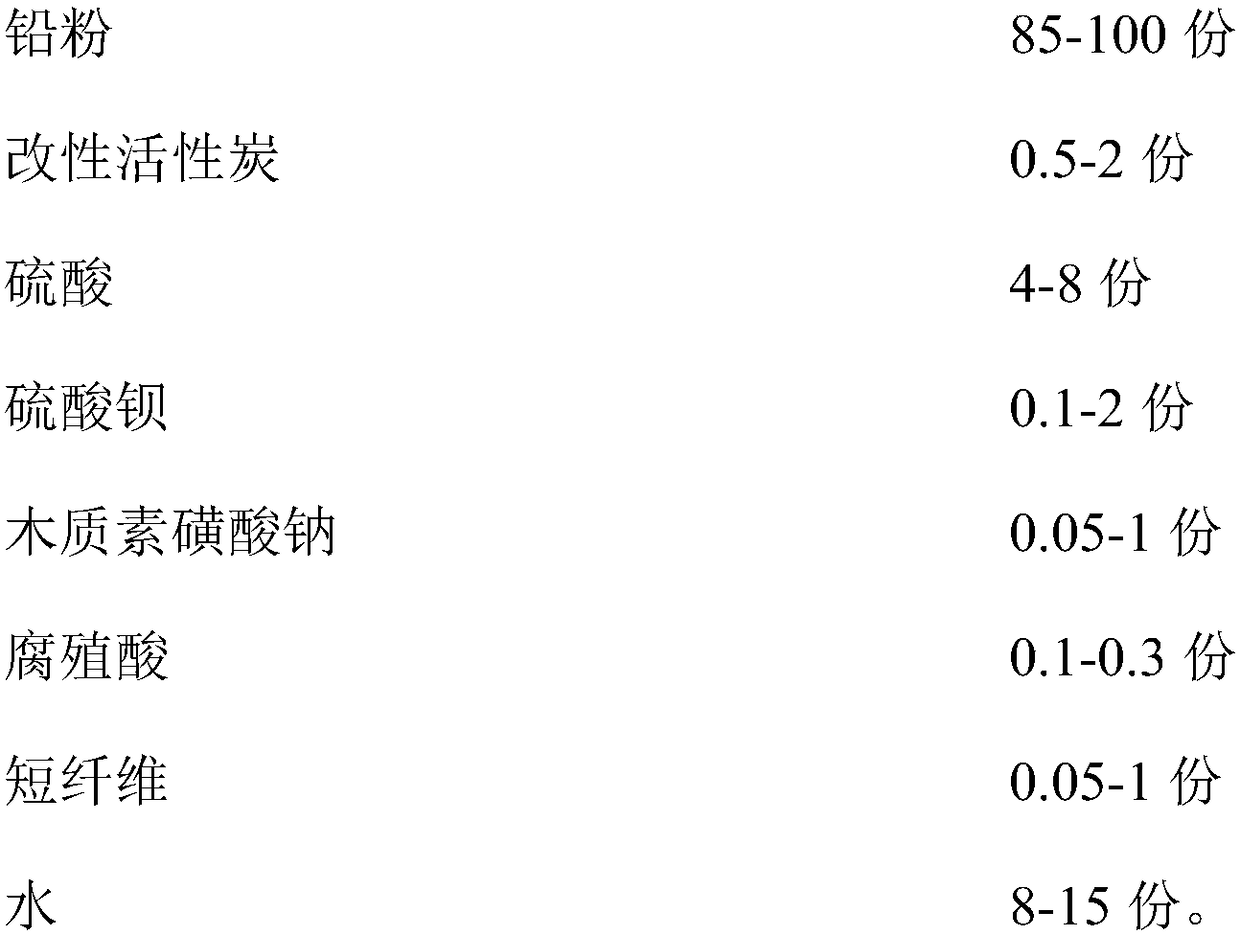

Method used

Image

Examples

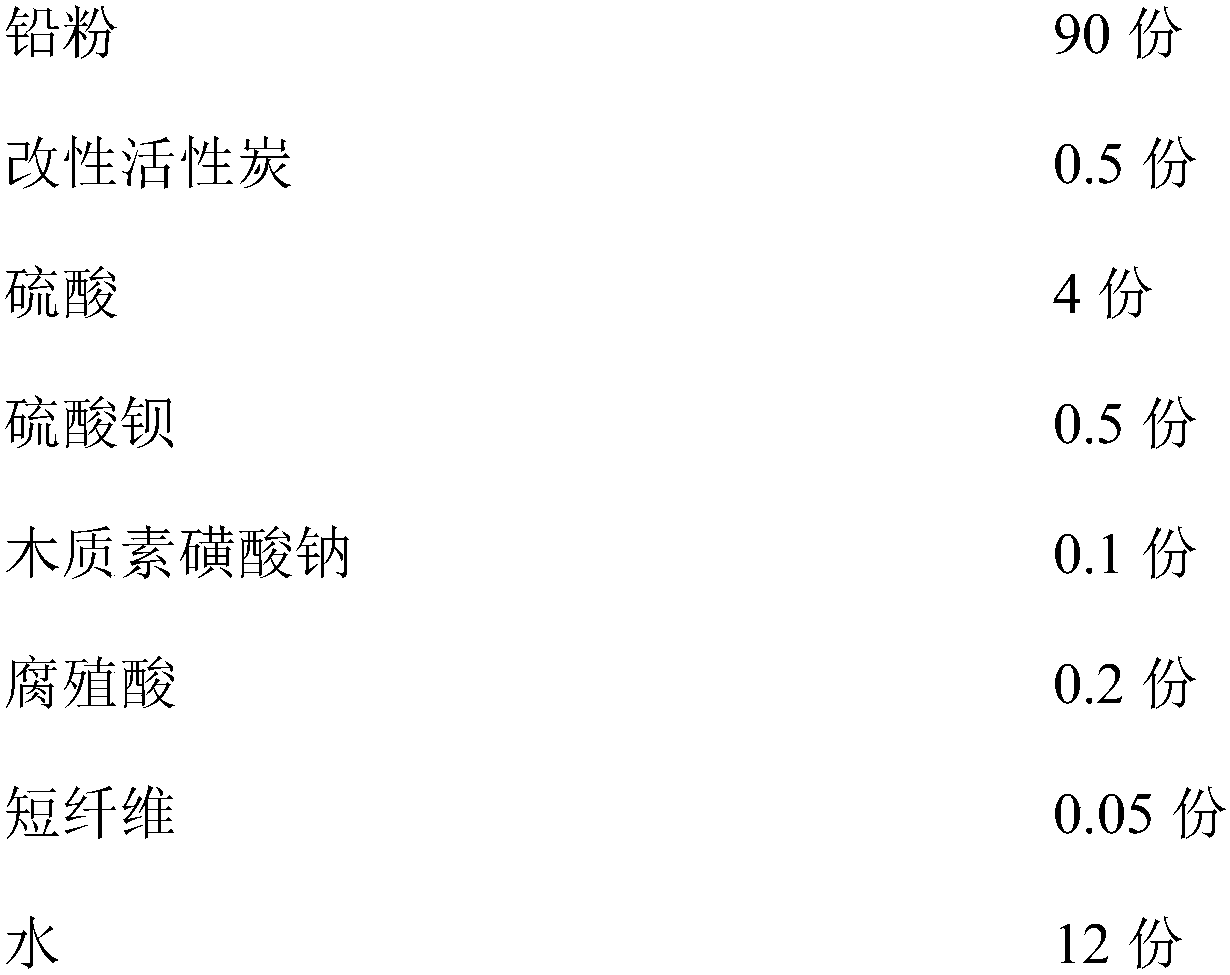

Embodiment 1

[0072] A preparation method of lead-carbon battery negative electrode paste, comprising the following steps:

[0073] (1) Mix 0.5 parts of biomass activated carbon with 1.5 parts of 2% dilute nitric acid and stir magnetically for 10 hours, filter with suction, wash with deionized water 6 times until the filtrate is neutral, then put it in a blast oven and dry it at 80°C for 10 hours. .

[0074] (2) Wet mix all the modified activated carbon samples dried in step (1) with 6 parts of deionized water, and stir in vacuum for 2 hours to obtain the first mixed slurry; add 90 parts of lead powder to the first mixed slurry and continue mixing 2h to obtain the second mixed slurry; 0.5 parts of barium sulfate, 0.1 parts of sodium lignosulfonate, 0.2 parts of humic acid, and 0.05 parts of short fibers (the short fibers are polyester short fibers with a diameter of 10 μm and a length of 10 mm) Stir and mix with the second mixture for 4 hours to obtain the third mixed slurry. Add the rema...

Embodiment 2

[0082] A preparation method of lead-carbon battery negative electrode paste, comprising the following steps:

[0083] (1) Mix 0.5 parts of biomass activated carbon with 1.5 parts of 2% dilute hydrogen peroxide solution, stir magnetically for 10 hours, filter with suction, wash with deionized water for 6 times until the filtrate is neutral, and then put it in a blast oven to dry at 80°C 10h, standby.

[0084] (2) Wet mix all the modified activated carbon samples dried in step (1) with 6 parts of deionized water, and stir in vacuum for 2 hours to obtain the first mixed slurry; add 90 parts of lead powder to the first mixed slurry and continue mixing 2h to obtain the second mixed slurry; 0.5 part of barium sulfate, 0.1 part of sodium lignosulfonate, 0.2 part of humic acid, short fiber (short fiber is polyacrylonitrile short fiber, diameter is 20 μm, length is 20mm) 0.05 Part and the second mixture were stirred and mixed for 4h to obtain the third mixed slurry. Add the remaining...

Embodiment 3

[0092] A preparation method of lead-carbon battery negative electrode paste, comprising the following steps:

[0093] (1) Mix 0.5 parts of biomass activated carbon with 1.5 parts of 2% dilute ammonium persulfate solution, stir magnetically for 10 hours, filter with suction, wash with deionized water for 6 times until the filtrate is neutral, and then put it in a blast oven to dry at 80°C 10h, standby.

[0094](2) Wet mix all the modified activated carbon samples dried in step (1) with 6 parts of deionized water, and stir in vacuum for 2 hours to obtain the first mixed slurry; add 90 parts of lead powder to the first mixed slurry and continue mixing 2h, obtain the second mixed slurry; 0.5 part of barium sulfate, 0.1 part of sodium lignosulfonate, 0.2 part of humic acid, short fiber (be polyester short fiber, diameter is 30 μ m, length is 10 mm) 0.05 part and The second mixture was stirred and mixed for 4 h to obtain a third mixed slurry. Add the remaining 6 parts of deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com