Preparation method of lithium ion capacitor

A technology of capacitors and lithium ions, which is applied in the field of preparation of lithium ion capacitors, can solve the problems of large internal resistance and low high-rate cycle life, achieve reasonable process installation, improve high-rate cycle life, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

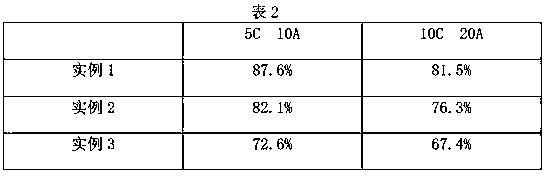

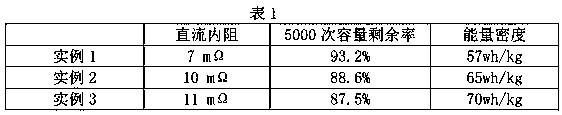

Embodiment 1)

[0019] The preparation method of the lithium ion capacitor of the present embodiment is implemented by the following steps:

[0020] ①Preparation of positive current collector: mix 60 parts by weight of conductive carbon black, 30 parts by weight of carbon nanotubes and graphene (wherein 25 parts by weight of carbon nanotubes, 5 parts by weight of graphene) and 10 parts by weight of butane After the styrene rubber is mixed, the slurry is prepared after stirring and high-speed ball milling. The prepared slurry is coated on an aluminum substrate with a purity of 99.7% and a thickness of 20 microns. The coating thickness is 1 micron. After coating, 90 °C and air-dried for 1 hour to obtain the desired positive electrode current collector.

[0021] ②Preparation of positive pole piece: Li(Ni0.5Co0.2Mn0.3)O2 and activated carbon are made into a mixture with a mass ratio of 1:1.5, and the mixture is pre-mixed at room temperature for 5 hours; take 80 parts by weight of the mixture Mix...

Embodiment 2)

[0030] The preparation method of the lithium ion capacitor of the present embodiment is implemented by the following steps:

[0031] ①Preparation of the positive current collector: a mixture of 55 parts by weight of conductive carbon black, 25 parts by weight of carbon nanotubes and graphene (wherein 20 parts by weight of carbon nanotubes, 5 parts by weight of graphene) and 20 parts by weight of butane After the styrene rubber is mixed, the slurry is prepared after stirring and high-speed ball milling. The prepared slurry is coated on an aluminum substrate with a purity of 99.7% and a thickness of 25 microns. The coating thickness is 2 microns. After coating, 100 °C and air-dried for 1 hour to obtain the desired positive electrode current collector.

[0032] ②Preparation of positive pole piece: Li(Ni0.5Co0.2Mn0.3)O2 and activated carbon are made into a mixture with a mass ratio of 1:1.3. The mixture is pre-mixed at room temperature for 3 hours, and 85 parts by weight of the mi...

Embodiment 3)

[0041] The preparation method of the lithium ion capacitor of the present embodiment is implemented by the following steps:

[0042] ①Preparation of the positive current collector: a mixture of 50 parts by weight of conductive carbon black, 20 parts by weight of carbon nanotubes and graphene (wherein 15 parts by weight of carbon nanotubes, 5 parts by weight of graphene) and 15 parts by weight of butane After the styrene rubber is mixed, the slurry is prepared after stirring and high-speed ball milling. The prepared slurry is coated on an aluminum substrate with a purity of 99.7% and a thickness of 30 microns. The coating thickness is 3 microns. After coating, 130 °C and dried for 1 hour in air blast to obtain the desired positive electrode current collector.

[0043] ②Preparation of positive pole piece: Li(Ni0.5Co0.2Mn0.3)O2 and activated carbon are made into a mixture with a mass ratio of 1:1. The mixture is pre-mixed at room temperature for 2 hours, and 90 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com