High-strength high-ductility low-density steel plate of 1200 MPa grade and manufacturing method thereof

A high-strength, high-plastic technology, applied in the field of advanced high-strength steel production, can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

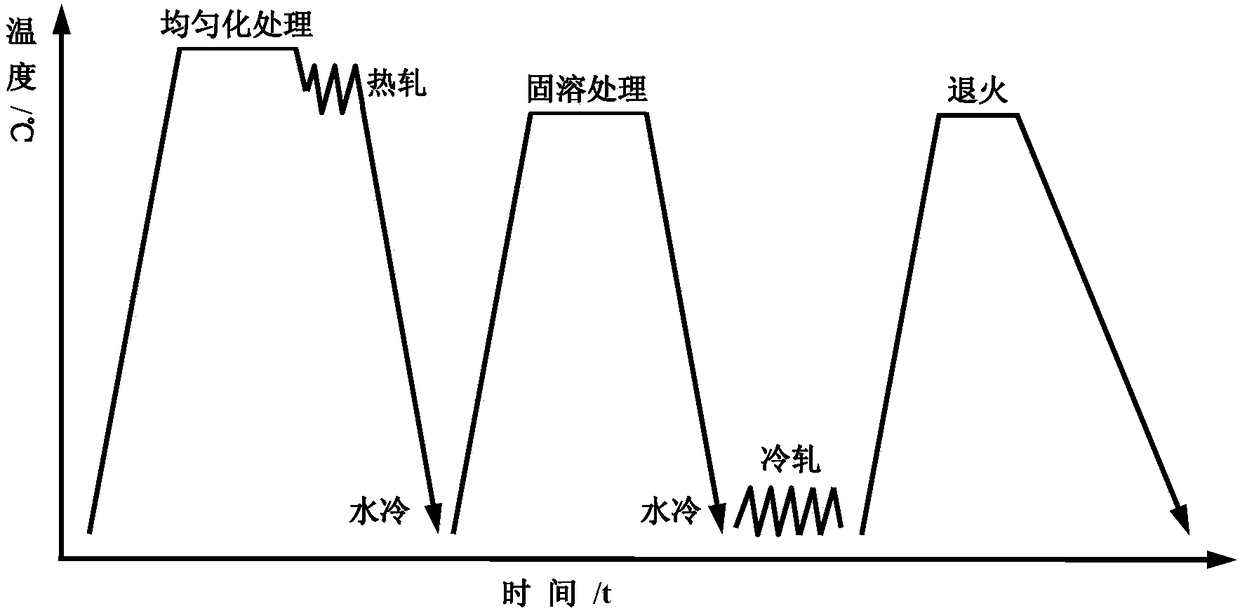

Method used

Image

Examples

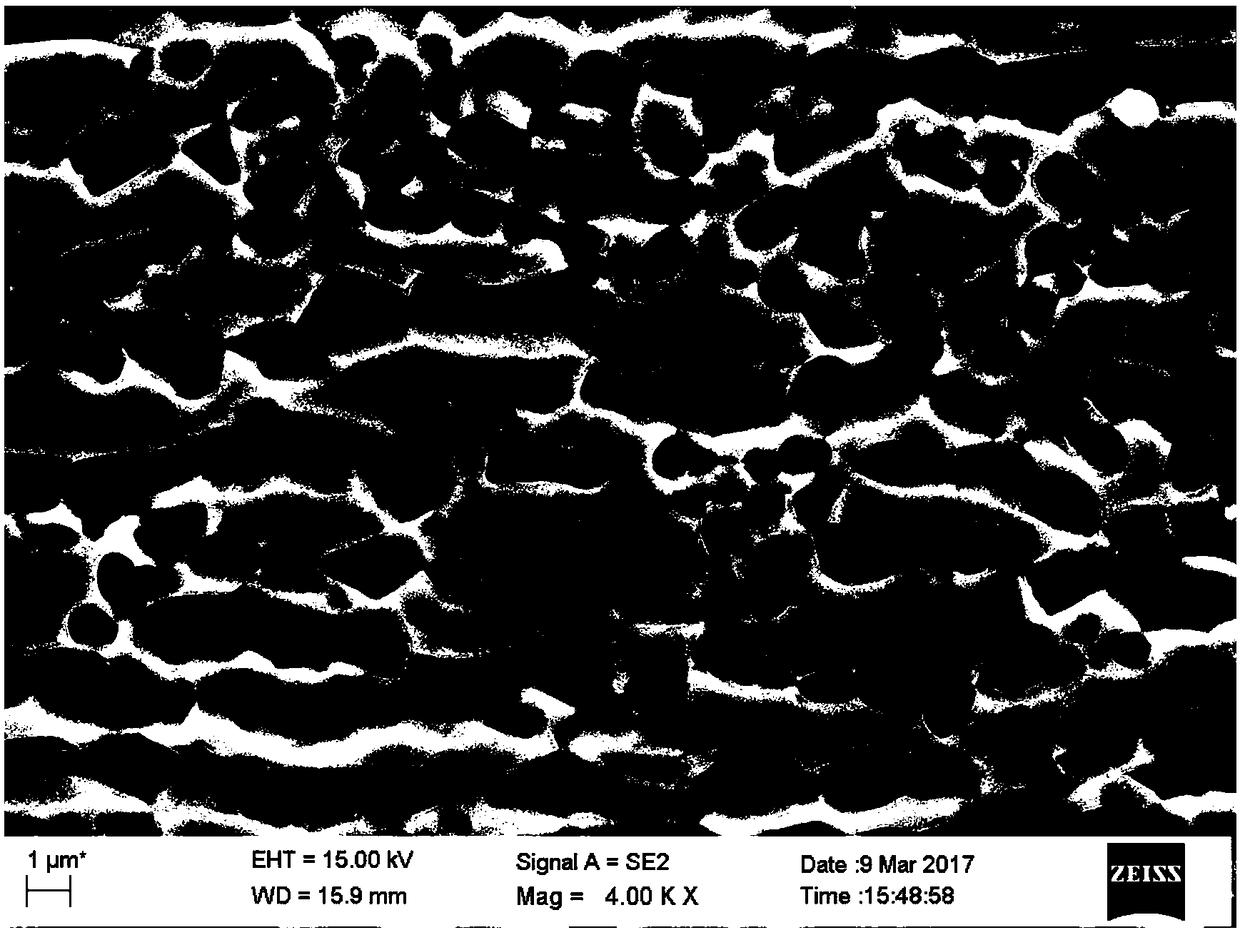

Embodiment 1

[0035] Molten steel is smelted in a vacuum induction furnace, and cast ingots are obtained after casting, and its composition by mass percentage is: C0.9%, Mn 15%, Al 8%, Ni 1.3%, Ti 0.03%, Si 0.06%, S 0.002% , P 0.002%, the balance is Fe and unavoidable impurities;

[0036]The ingot was heated to 1180°C and held for 1 hour, followed by 9 passes of hot rolling, the starting and finishing temperatures were 1050°C and 820°C, respectively, and water-cooled to room temperature after hot rolling to obtain a 4mm thick hot-rolled plate; The total reduction rate of hot rolling is 96.9%;

[0037] Heat the hot-rolled sheet to 900°C and keep it warm for 2 hours, then water-cool to room temperature to obtain a solution-treated sheet;

[0038] Pickling the solution-treated sheet and then cold-rolling it to a thickness of 1.2mm to obtain a cold-rolled sheet; the total cold-rolling reduction rate is 70%;

[0039] Heat the cold-rolled sheet to 880°C and hold it for 10 minutes, then air-cool...

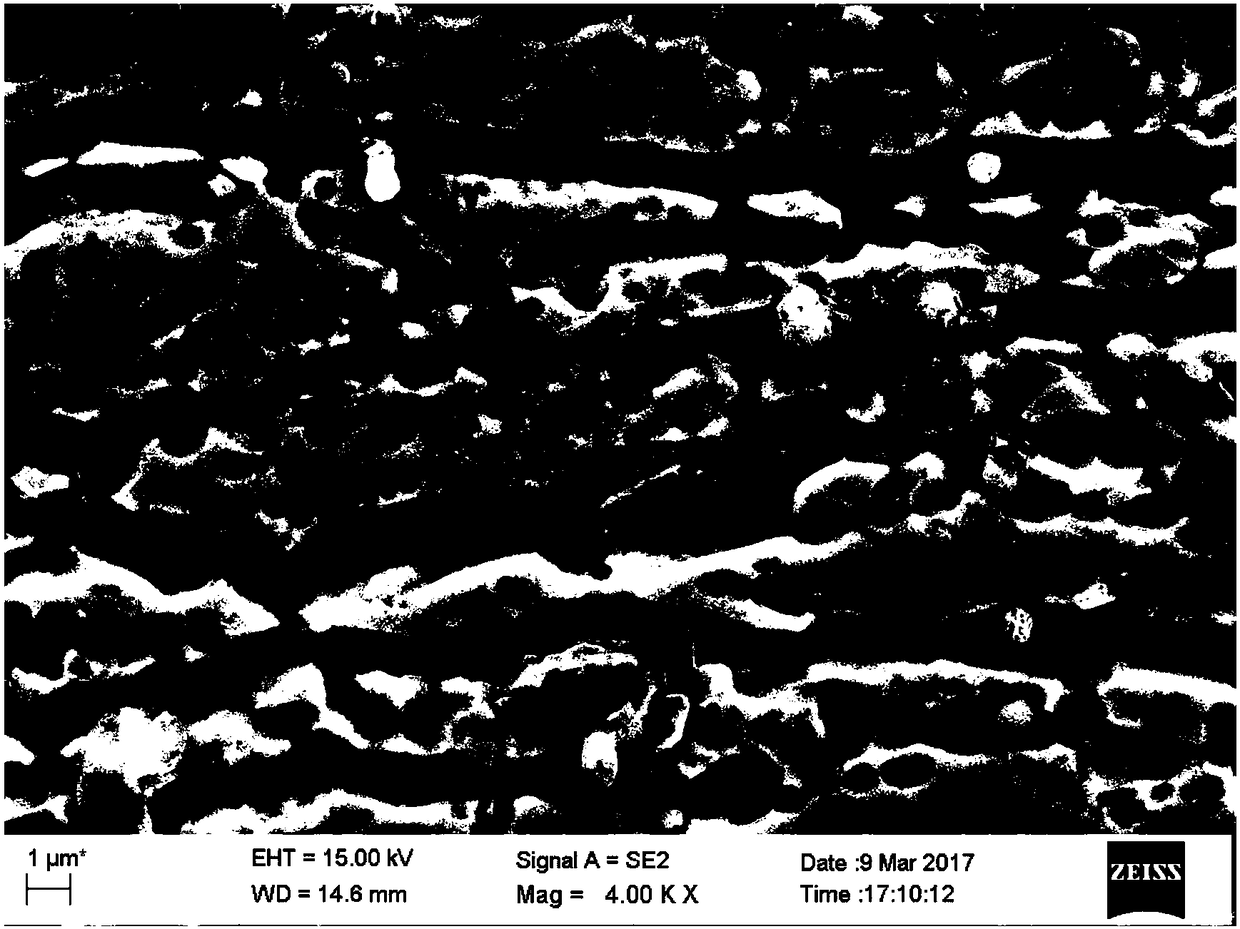

Embodiment 2

[0041] Method is with embodiment 1, and difference is:

[0042] (1) The composition of the ingot by mass percentage is: C 0.85%, Mn 16.4%, Al 9%, Ni 2.6%, Si0.04%, Ti 0.05%, S 0.002%, P 0.002%;

[0043] (2) Heating to 1200°C and keeping it warm for 2 hours, followed by 10 passes of hot rolling, the starting and finishing temperatures were 1060°C and 850°C respectively, and water cooled to room temperature after hot rolling to obtain a 4.5mm thick hot-rolled sheet ;The total reduction rate of hot rolling is 96.5%;

[0044] (3) Heat the hot-rolled plate to 1050°C and keep it warm for 1h;

[0045] (4) cold rolling to a thickness of 1 mm to obtain a cold rolled plate; the total reduction rate of cold rolling is 78%;

[0046] (5) Heating to 900°C and keeping it warm for 15min, air cooling to room temperature (cooling rate 22°C / s), the tensile strength of the 1200MPa high-strength, high-plasticity low-density steel plate is 1258MPa, the elongation is 35%, and the density is 6.8g / c...

Embodiment 3

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The composition of the ingot by mass percentage is: C 0.92%, Mn 18.3%, Al 10.2%, Ni 3.6%, Si0.03%, S 0.002%, P 0.002%;

[0050] (2) Heating to 1130°C and keeping it warm for 1.5h, followed by 11 passes of hot rolling, the starting and finishing temperatures were 1080°C and 860°C respectively, and water cooled to room temperature after hot rolling to obtain a 3.8mm thick hot rolled plate; the total reduction rate of hot rolling is 97.1%;

[0051] (3) Heat the hot-rolled plate to 1100°C and keep it warm for 0.5h;

[0052] (4) Cold rolling to a thickness of 0.7mm to obtain a cold-rolled sheet; the total reduction rate of cold rolling is 82%;

[0053] (5) Heating to 970°C and keeping it warm for 2min, air cooling to room temperature (cooling rate 28°C / s), the tensile strength of the 1200MPa high-strength, high-plasticity low-density steel plate is 1279MPa, the elongation is 31%, and the density is 6.6g / cm 3 ; m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com