Superhydrophilic self-cleaning coating sol, and preparation method and use method thereof

A super-hydrophilic coating technology, applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of low photocatalytic activity, high amorphous content, complex preparation methods, etc. Simple, low-cost, and easy-to-control operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

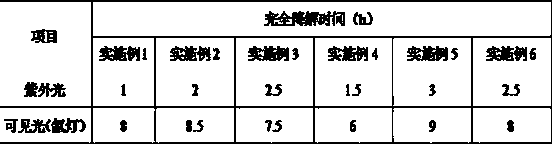

Examples

Embodiment 1

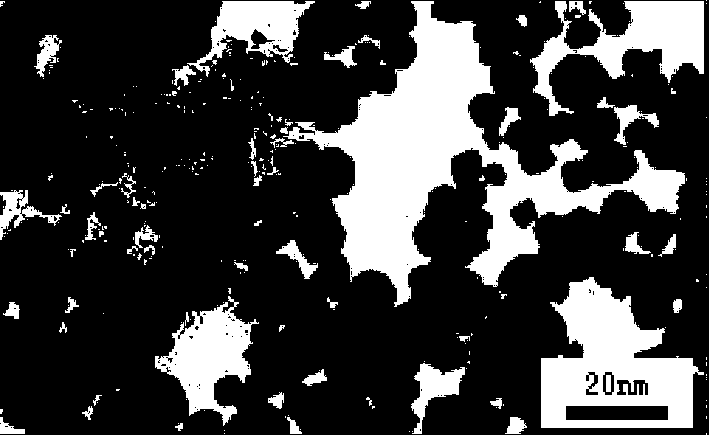

[0041] (1) Preparation of nano-titanium dioxide solution

[0042] Mix 10g of anatase-type nano-titanium dioxide (average particle size is 10nm), 0.1g modifier, and 1000g of isopropanol, and disperse evenly under ultrasonic conditions to obtain a nano-titanium dioxide solution;

[0043] (2) Preparation of superhydrophilic self-cleaning coating sol

[0044] Mix the nano-titanium dioxide solution obtained in step (1), 5000 g of an organopolysilazane solution with a solid content of 10%, and xylene, stir at 5°C for 20 hours, seal and store, and obtain a superhydrophilic solution with a solid content of 3%. Self-cleaning coating sol. The inorganic polysilazane solution used comprises inorganic polysilazane, n-butyl ether and catalyst 4,4'-trimethylenebis(1-methylpiperidine), wherein the mass ratio of inorganic polysilazane and catalyst 10:0.01.

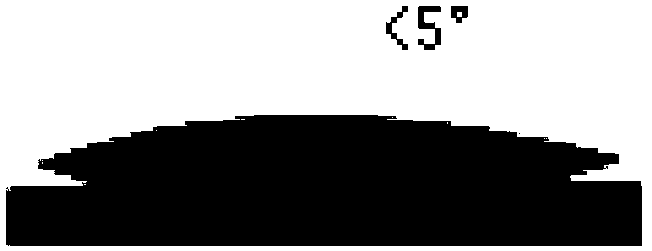

[0045] Apply the prepared superhydrophilic self-cleaning coating sol film on the substrate, and cure at 80° C. for 24 hours to obtain ...

Embodiment 2

[0047] (1) Preparation of nano-titanium dioxide solution

[0048] Mix 10g of anatase-type nano-titanium dioxide (average particle size of 2nm), 1g of modifier, and 800g of ethanol, and disperse evenly under ultrasonic conditions to obtain a nano-titanium dioxide solution;

[0049] (2) Preparation of superhydrophilic self-cleaning coating sol

[0050]Mix the nano-titanium dioxide solution obtained in step (1), 1000 g of an organopolysilazane solution with a solid content of 10%, and methanol, stir at 25°C for 10 hours, and store it in a sealed container to obtain a superhydrophilic silicone with a solid content of 3%. Clean coating sol. The inorganic polysilazane solution used comprises inorganic polysilazane, xylene and catalyst 1-methylpiperidine, wherein the mass ratio of inorganic polysilazane and catalyst is 10:0.001.

[0051] Apply the prepared superhydrophilic self-cleaning coating sol film on the substrate, and cure at 60° C. for 4 hours to obtain a superhydrophilic c...

Embodiment 3

[0053] (1) Preparation of nano-titanium dioxide solution

[0054] Mix 10g of anatase-type nano-titanium dioxide (average particle size is 5nm), 0.8g modifier, and 1000g of isopropanol, and disperse evenly under ultrasonic conditions to obtain a nano-titanium dioxide solution;

[0055] (2) Preparation of superhydrophilic self-cleaning coating sol

[0056] Mix the nano-titanium dioxide solution obtained in step (1), 10,000 g of an organopolysilazane solution with a solid content of 2%, and n-butanol, stir at 35°C for 40 hours, and seal and store to obtain a superphilic acid with a solid content of 1%. Water self-cleaning coating sol. The inorganic polysilazane solution used comprises inorganic polysilazane, n-butyl ether and catalyst 4,4'-trimethylenebis(1-methylpiperidine), wherein the mass ratio of inorganic polysilazane and catalyst is 10:1.

[0057] Apply the prepared superhydrophilic self-cleaning coating sol film on the substrate, and cure at 50° C. for 10 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com