Preparation method for synthesizing MIL-53(Al)-AO2 on basis of metal-organic framework of amidoxime

A metal-organic framework and amidoxime technology, which is applied in the field of metal-organic framework synthesis MIL-53-AO2 preparation, can solve the problems of unfavorable uranium extraction and reuse, low selective adsorption capacity, etc., and achieve improved retention and adsorption capacity and efficient materials , the effect of large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific embodiment the present invention is described in further detail:

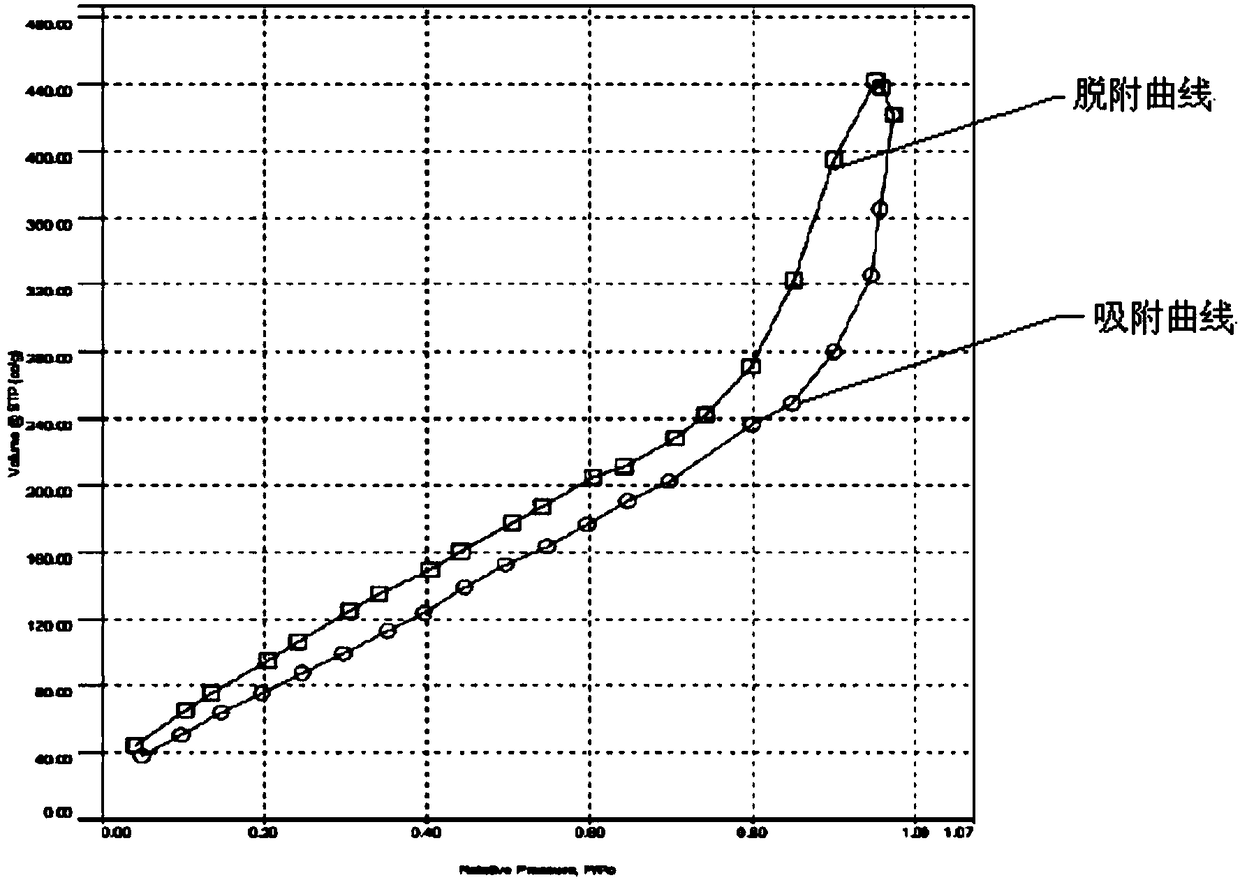

[0015] Step S1: with 0.56g of 2-aminoterephthalic acid and 1.125g of Al(NO 3 ) 3 9H 2 O was dissolved in 80mL N-N dimethylformamide DMF and 20mL deionized water mixed liquid, after fully stirring, the mixed liquid was placed in a 200mL polytetrafluoroethylene-lined stainless steel reaction kettle, and the reaction kettle was placed in a vacuum drying oven Adjust the temperature to 150°C and react for 24 hours. After the reaction is over, let it cool down to room temperature naturally, filter it with a polytetrafluoroethylene microporous filter membrane with a pore size of 0.22 μm, and wash it repeatedly with DMF solution to obtain the MIL-53 (Al )-NH 2 mixture A1.

[0016] Step S2: Put the mixture A1 in step S1 in a round-bottomed flask, add DMF again to wash the impurities, heat and reflux with a reflux device to remove the residual 2-aminoterephthalic acid in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com