A kind of preparation method of novel heavy oil viscosity reducer

A heavy oil viscosity reducer, a new type of technology, applied in the field of preparation of new heavy oil viscosity reducer, can solve the problem of lack of viscosity reducer in extra thick crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Add 0.1mol 1,4-diazacyclohexane and 100ml absolute ethanol to a 500ml three-necked reaction flask, cool to 0°C, and slowly add 0.1mol 1,2,3,5-tetra-p-toluenesulfonic acid inosoline under stirring Alcohol ester, keep the temperature below 4°C, it takes 2 hours, continue to stir and keep warm for 3 hours after the addition is complete; slowly add 0.2mol N,N-dimethyl behenyl tertiary amine and 50ml of absolute ethanol dropwise, need After 1 hour, add 30ml of distilled water, raise the temperature to 55°C, and stir for 3 hours to obtain a light yellow viscous liquid.

Embodiment 2

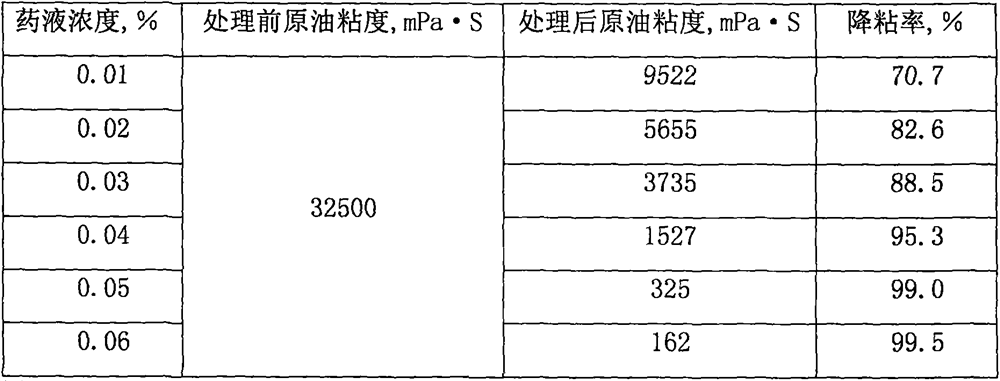

[0010] The crude oil sample is very thick crude oil from Tahe Oilfield in Xinjiang, and its viscosity at 85°C is measured by BROOKFILD DV-III+ rheometer to be 32500mPa·s. The product prepared in Example 1 is prepared into aqueous solutions with different chemical concentrations , with the mass ratio of oil to water being 7:3, the drug solution was added to the crude oil, the temperature was raised to 85°C, left standing for 24h, gently shaken for 5min, and the viscosity of the emulsion was measured at 85°C. Treated crude oil viscosity and viscosity reduction rate are as shown in Table 1 below, as can be seen from Table 1, the product prepared in Example 1 significantly reduced the viscosity of Xinjiang Tahe extra thick crude oil, and when the drug concentration was greater than 0.05%, Viscosity reduction effect is very obvious.

[0011] Table 1 Viscosity-reducing effect of different concentrations of the reagents of Example 1 on Tahe heavy oil

[0012]

Embodiment 3

[0014] The product prepared in Example 1 was used to prepare an aqueous solution with a mass percentage of 0.05%. Using conditions similar to those described in Example 2, at 85°C, treat heavy oil samples with different viscosities with the prepared medicament solution, and measure the viscosity of the heavy oil before and after treatment at 85°C. The results are shown in Table 2 . It can be seen from Table 2 that the viscosity reducer of the present invention can effectively reduce the viscosity of different types of heavy oil.

[0015] Table 2 The viscosity-reducing effect of the agent in Example 1 on heavy oil samples with different viscosities

[0016] crude oil sample Crude oil viscosity, mPa·s Crude oil viscosity after treatment, mPa·s Viscosity reduction rate, % 1# 45180 208 99.5 2# 32500 161 99.5 3# 20845 120 99.4 4# 12380 106 99.1 5# 8590 102 98.8 6# 3621 85 97.7

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com