Conduction type bituminous mixture, preparation method and self-snow-melting system of conduction type bituminous mixture

A conductive asphalt mixture technology, applied in the field of conductive asphalt mixture, self-melting snow system, and preparation, to save costs, inhibit freezing, and improve driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

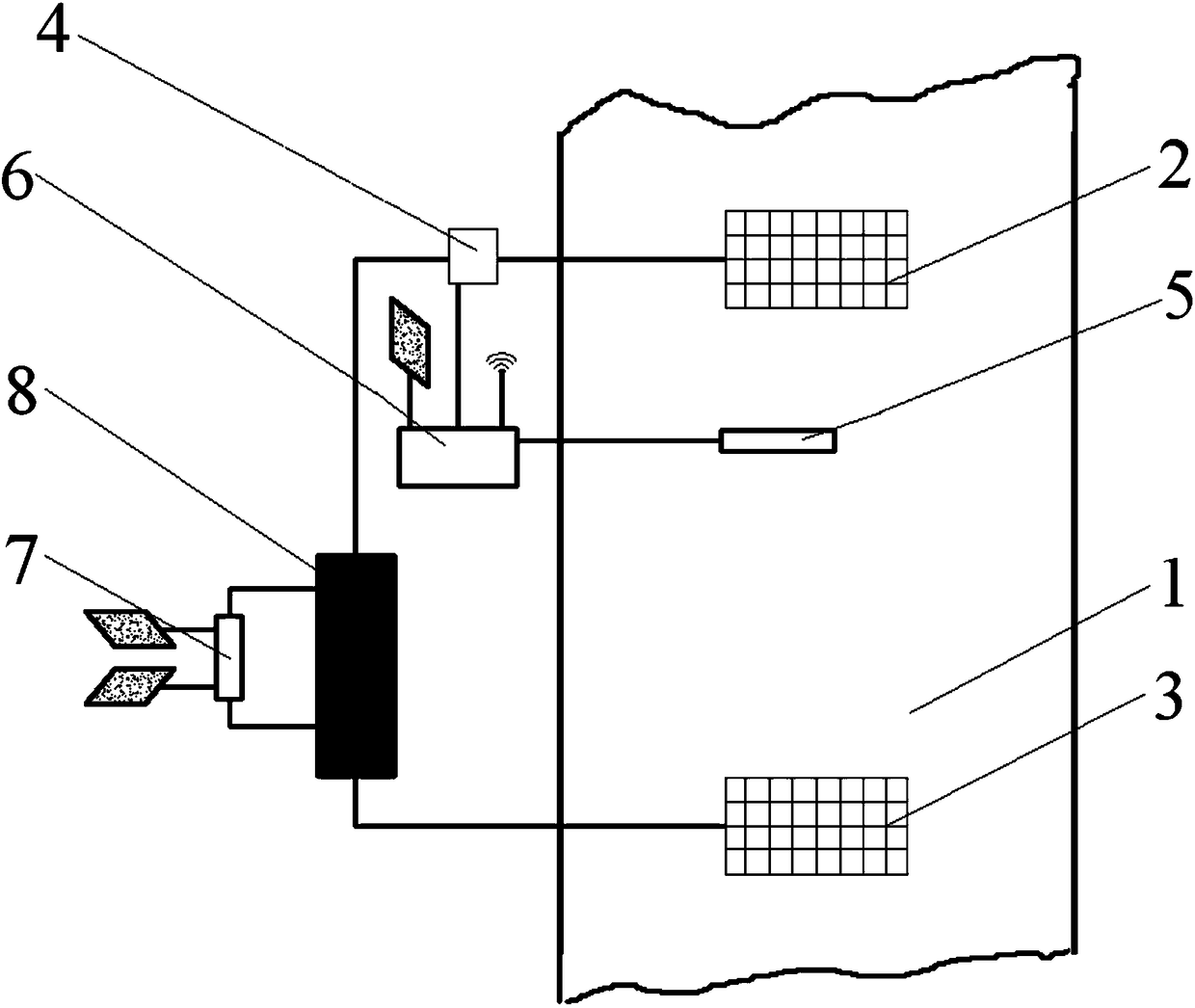

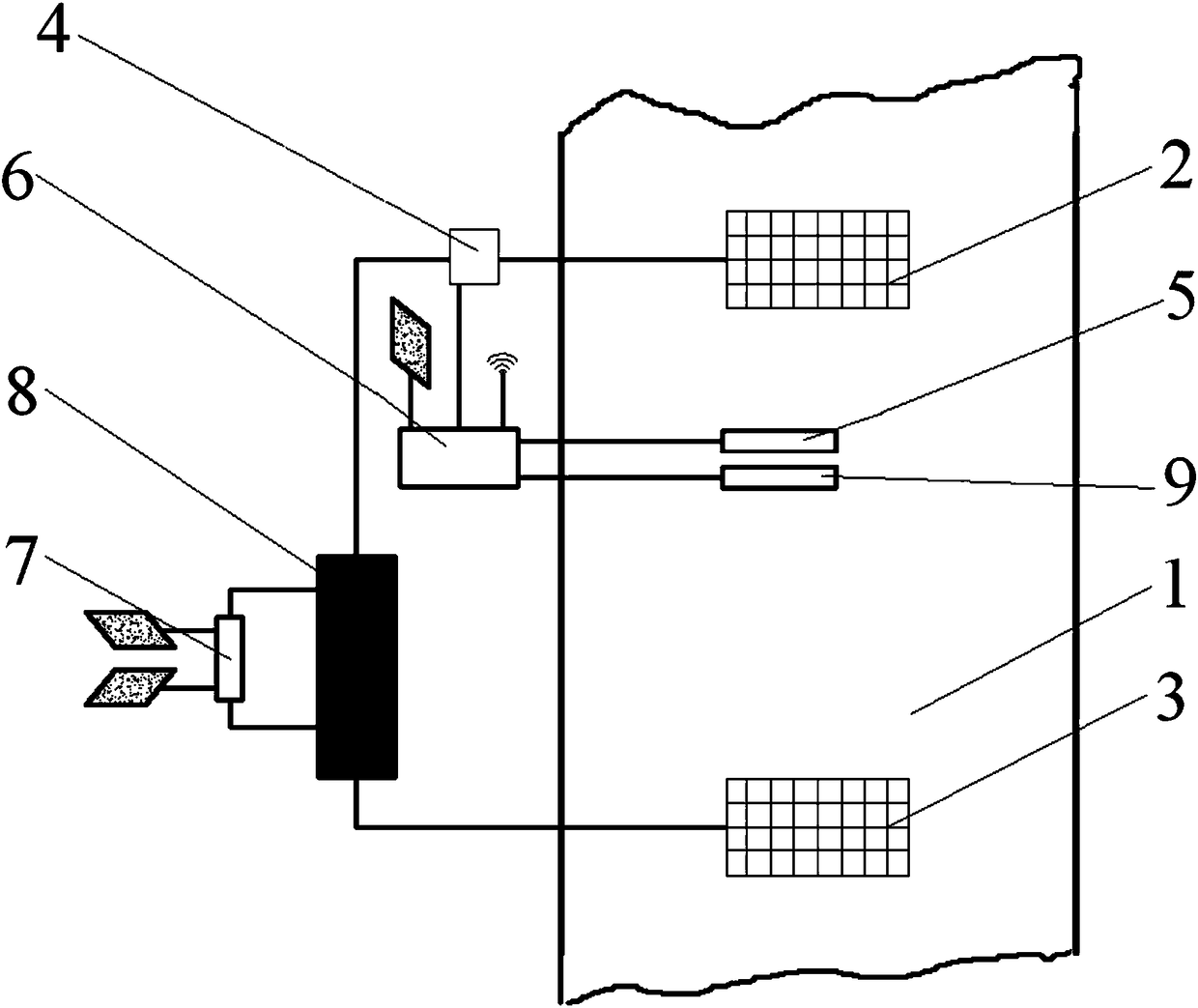

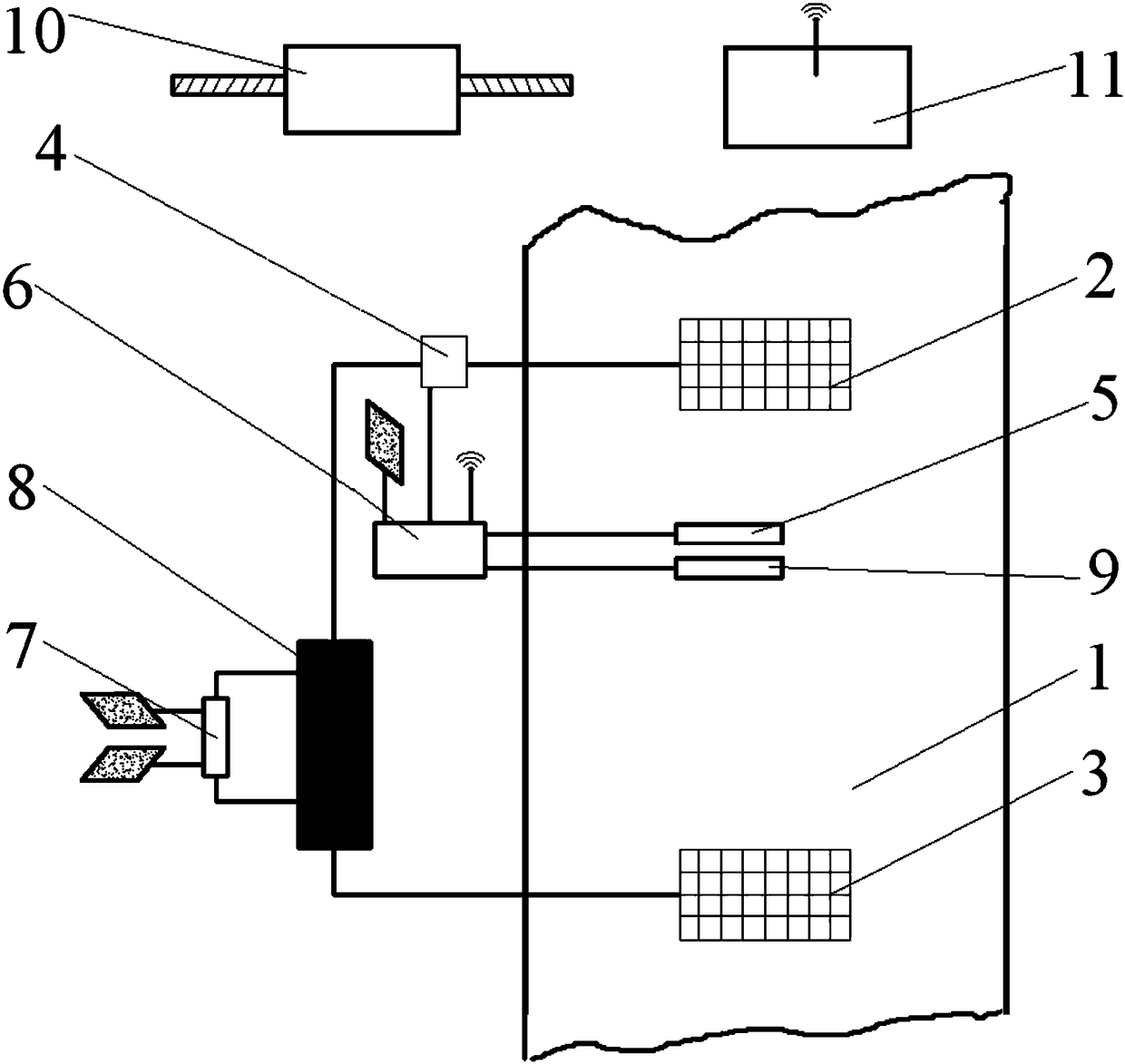

Method used

Image

Examples

Embodiment 1

[0042]A conductive asphalt mixture, including the following raw materials: coal gasification fine slag 6%, 0-3mm stone chips 26%, 3-5mm stone chips 12%, 5-10mm stone chips 36%, 10-15mm stone chips 20%, the mass ratio of asphalt to stone is 5.2:1.

[0043] The preparation method of the above-mentioned conductive asphalt mixture comprises the following preparation steps:

[0044] Step 1, put the coal gasification fine slag and stone into an oven and heat it to 182.5°C and keep it at a constant temperature to obtain the preheated coal gasification fine slag and stone for later use;

[0045] Step 2, put the asphalt in an oven and heat it to 165°C and keep it at a constant temperature to obtain the preheated asphalt for later use;

[0046] Step 3: Heat the mixing pot to 182.5°C, add the preheated coal gasification slag and stone materials, dry mix for 120 seconds, add the preheated asphalt, dry mix for 120 seconds, and the product is ready.

Embodiment 2

[0048] A conductive asphalt mixture, including the following raw materials: coal gasification fine slag 12%, 0-3mm stone chips 20%, 3-5mm stone chips 12%, 5-10mm stone chips 36%, 10-15mm stone chips 20%, the mass ratio of asphalt to stone is 5.6:1.

[0049] The preparation method of the above-mentioned conductive asphalt mixture comprises the following preparation steps:

[0050] Step 1, put the coal gasification fine slag and stone into an oven and heat it to 180°C and keep it at a constant temperature to obtain the preheated coal gasification fine slag and stone for later use;

[0051] Step 2, put the asphalt in an oven and heat it to 170°C and keep it at a constant temperature to obtain the preheated asphalt for later use;

[0052] Step 3: Heat the mixing pot to 180°C, add the preheated coal gasification fine slag and stone, dry mix for 120 seconds, add the preheated asphalt, dry mix for 120 seconds, and the product is ready.

Embodiment 3

[0054] A conductive asphalt mixture, including the following raw materials: coal gasification fine slag 18%, 0-3mm stone chips 14%, 3-5mm stone chips 12%, 5-10mm stone chips 36%, 10-15mm stone chips 20%, the mass ratio of asphalt to stone is 6.0:1.

[0055] The preparation method of the above-mentioned conductive asphalt mixture comprises the following preparation steps:

[0056] Step 1, put coal gasification fine slag and stone into an oven and heat to 185°C and keep at a constant temperature to obtain preheated coal gasification fine slag and stone for later use;

[0057] Step 2, put the asphalt in an oven and heat it to 160°C and keep it at a constant temperature to get the preheated asphalt for later use;

[0058] Step 3: Heat the mixing pot to 185°C, add the preheated coal gasification slag and stone, dry mix for 120 seconds, add the preheated asphalt, dry mix for 120 seconds, and the product is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com