A system for co-heating potassium hexafluoromanganate and antimony pentafluoride to produce fluorine gas and purify graphite

A technology of potassium hexafluoromanganate and antimony pentafluoride, which is applied in the direction of fluorine/hydrogen fluoride, fluorine, carbon compounds, etc., can solve problems such as ecological imbalance and ozone layer destruction, and achieve high environmental protection performance, good purification effect, and optimized equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

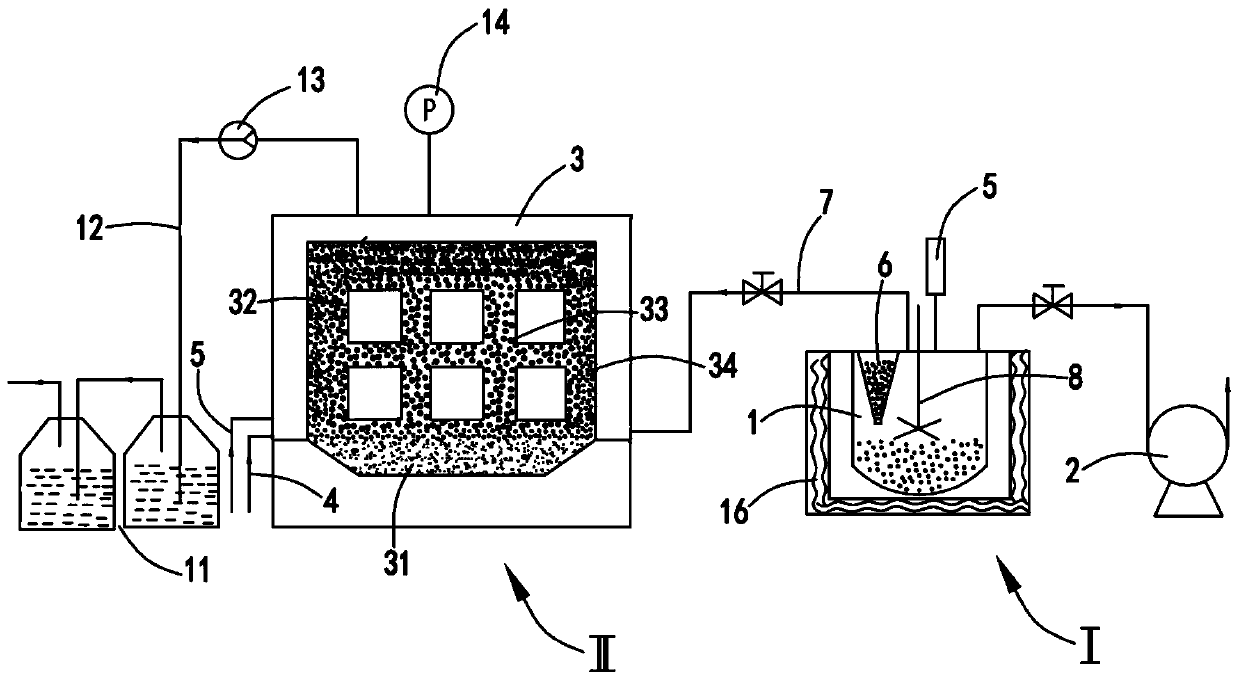

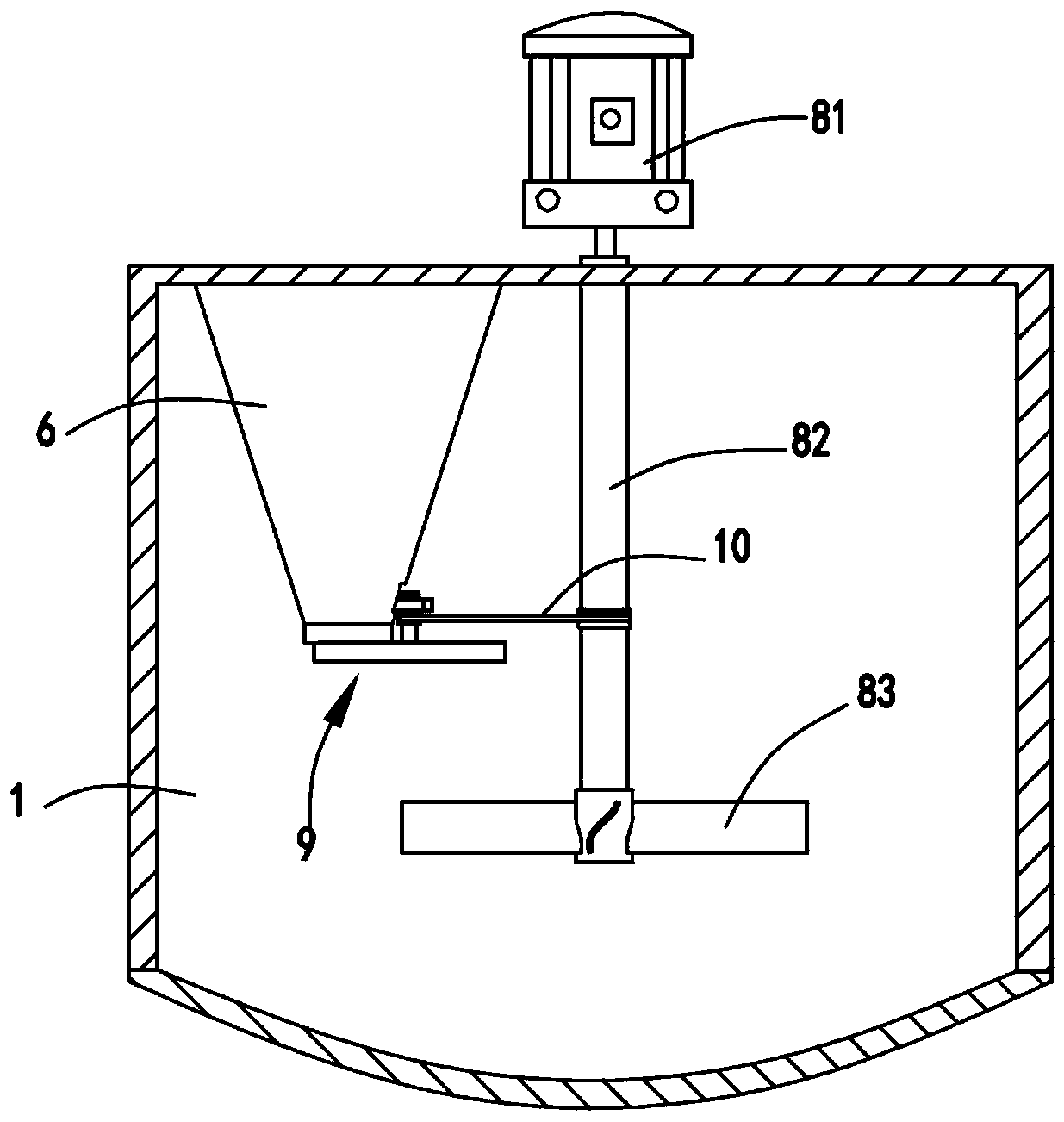

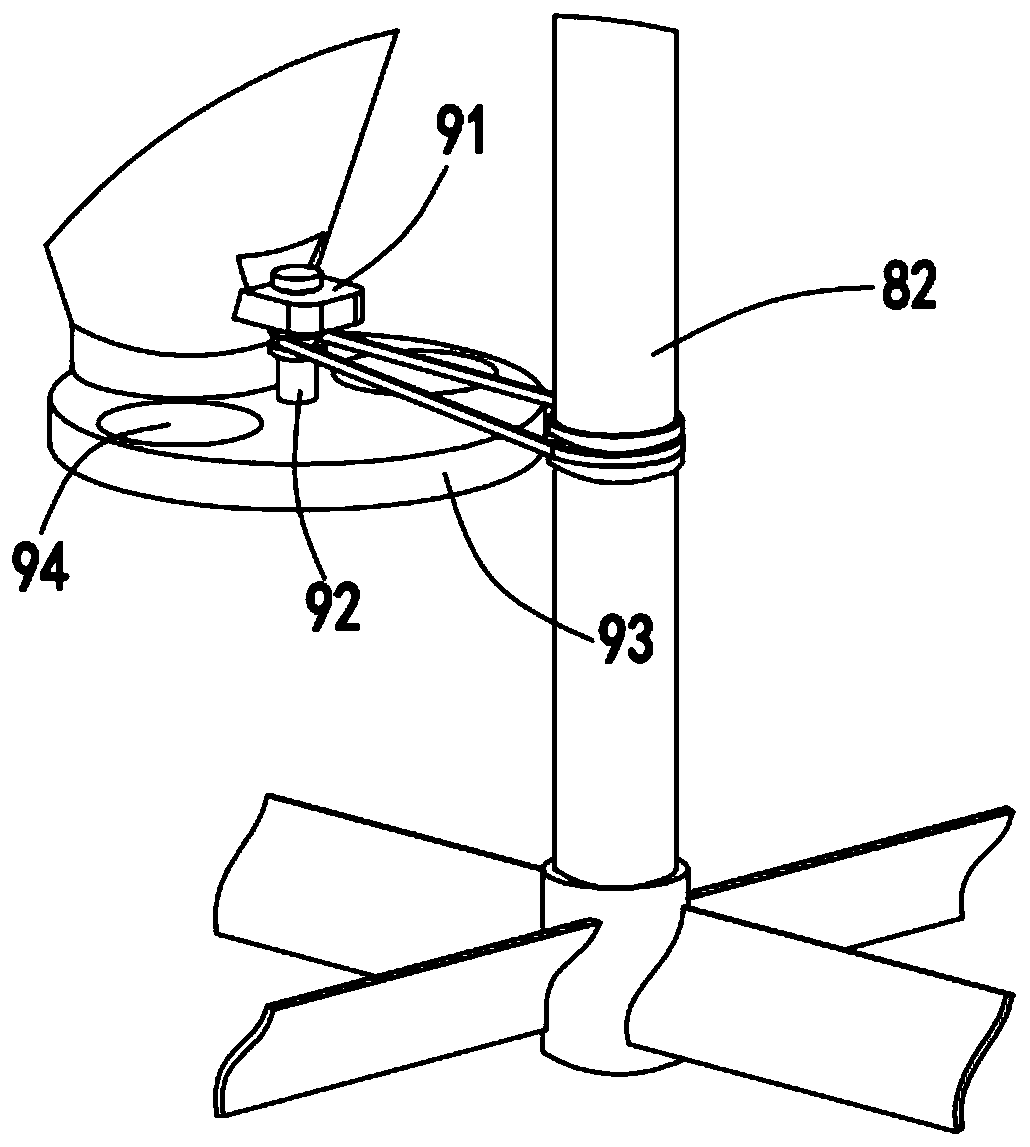

[0041] Such as figure 1 , figure 2 and image 3 As shown, the system for co-heating potassium hexafluoromanganate and antimony pentafluoride to produce fluorine gas to purify graphite includes a fluorine gas reaction unit I, and the fluorine gas reaction unit I includes:

[0042] A reactor 1 and a vacuum pump 2 for evacuating the inside of the reactor 1, a heater 3 for heating the reactor 1 is installed outside the reactor 1, and

[0043] Furnace body unit II, the furnace body unit II includes:

[0044] Furnace body 3, the bottom of described furnace body 3 is arranged with furnace bottom material 31, and graphite product is placed at furnace core 32, and graphite product is surrounded with resistance material 33, and the outer side of resistance material 33 is arranged with insulation material 34, and described One side of the furnace body 3 is provided with an inlet pipe a4 and an inlet pipe b5 for feeding nitrogen and chlorine gas into the furnace core 32 respectively. ...

Embodiment 2

[0055] Such as figure 2 As shown, as an improvement, one side of the furnace body 3 is also provided with an exhaust gas absorber 11, and the exhaust gas absorber 11 communicates with the furnace core 32 top of the furnace body 3 through the gas outlet pipe 12, and the gas outlet pipe 12 is provided with a Pump the gas in the furnace core 32 to the gas pump 13 of the tail gas absorber 11;

[0056] The top of the furnace body 3 is also provided with a pressure gauge 14 for monitoring the internal pressure of the furnace core 32 .

[0057] It should be noted that the tail gas absorber 11 is composed of several sodium hydroxide solution absorbers, and the fluorine gas and sodium hydroxide are removed by reaction, and the equation is 2F 2 +4NaOH→NaF+2H 2 O+O 2 , The gasified sodium fluoride is dissolved in the aqueous solution. In this embodiment, the waste gas generated by graphitization and purification is avoided by setting the tail gas absorber to be directly discharged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com