Gas cutting device for three-way workpiece end cap

A workpiece and gas cutting technology, which is applied in the field of three-way workpiece processing equipment, can solve the problems of easy damage to the saw blade, high price of the saw blade, and low production efficiency, and achieve the effect of fast cutting speed, novel structure and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

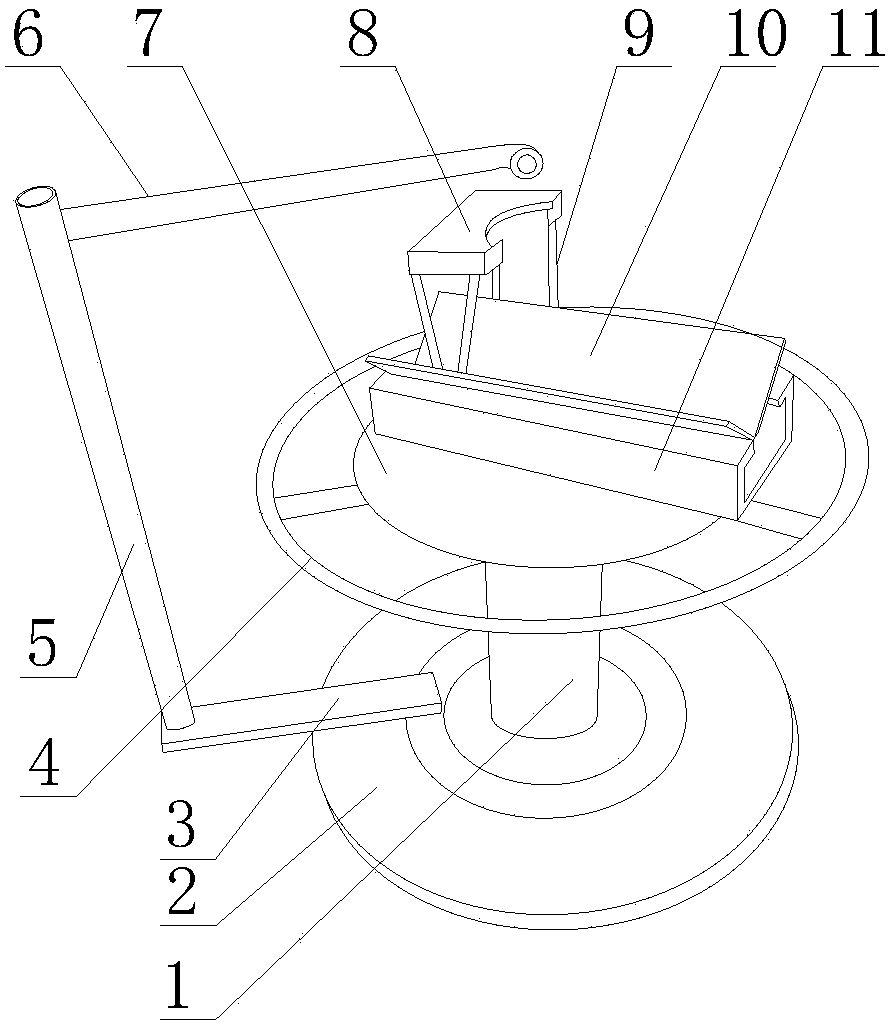

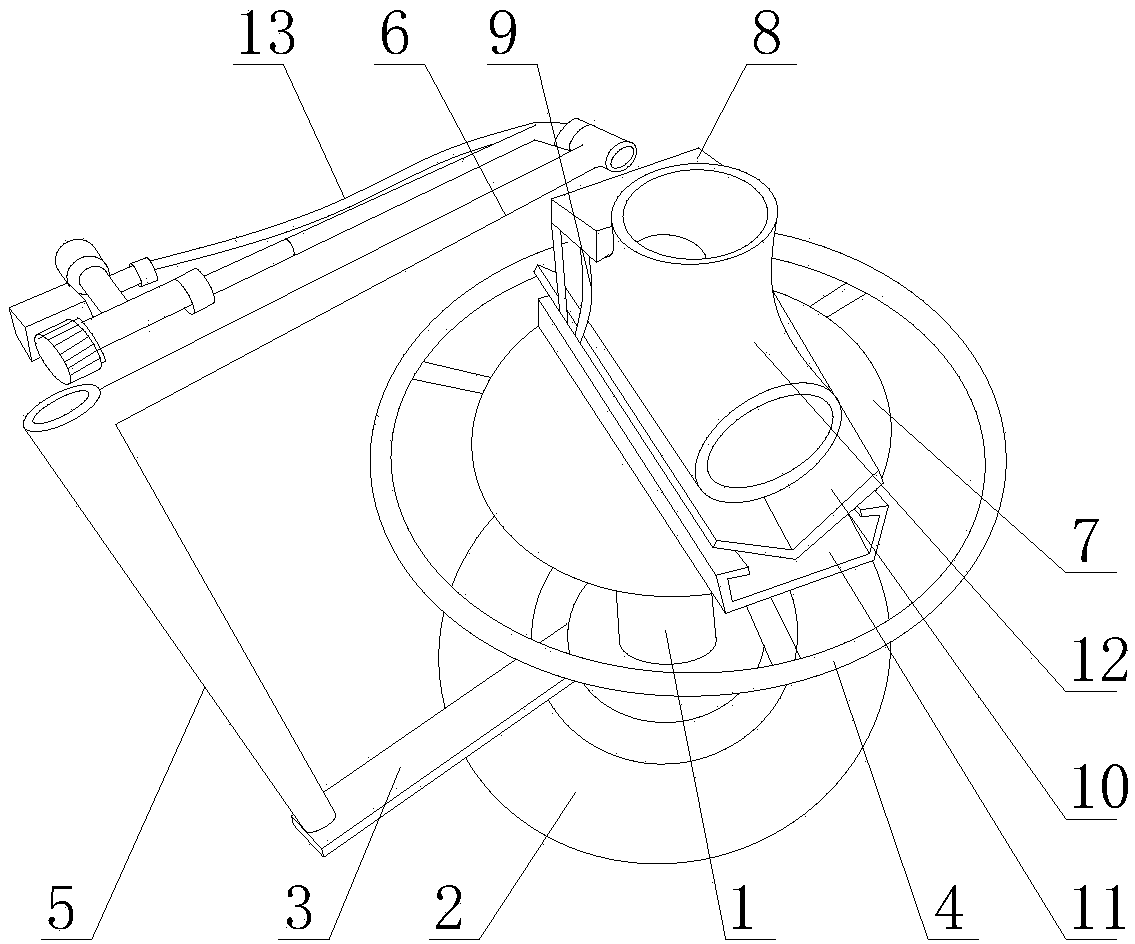

[0020] Such as figure 1 and figure 2 As shown, the equipment for gas cutting three-way workpiece end caps includes a fixed base 2, a rotary table 7, a torch fixing mechanism, and a three-way workpiece positioning mechanism. structure, the rotary table 7 and the base are flexibly connected through the support column 1, and the two ends of the support column 1 are respectively installed at the center of the rotary table 7 and the base to ensure the support stability during the rotation; the rotary table 7 The outer edge is ring-shaped and provided with a manual turntable 4, which is set in a ring-shaped structure, which is convenient for hand-held manipulation. The table 7 rotates; the torch fixing mechanism is set on the base, the cutting torch is erected horizontally on the torch fixing mechanism, and the end of the torch extends to the top of the rotary table 7; the three-way workpiece positioning mechanism is set on the rotary table 7 On, the three-way workpiece 12 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com