washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve problems such as inability to start dehydration operation, and achieve the effects of shortening the operation time, realizing the quantity, and eliminating the imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0036] Hereinafter, one Embodiment of this invention is described in detail based on drawing.

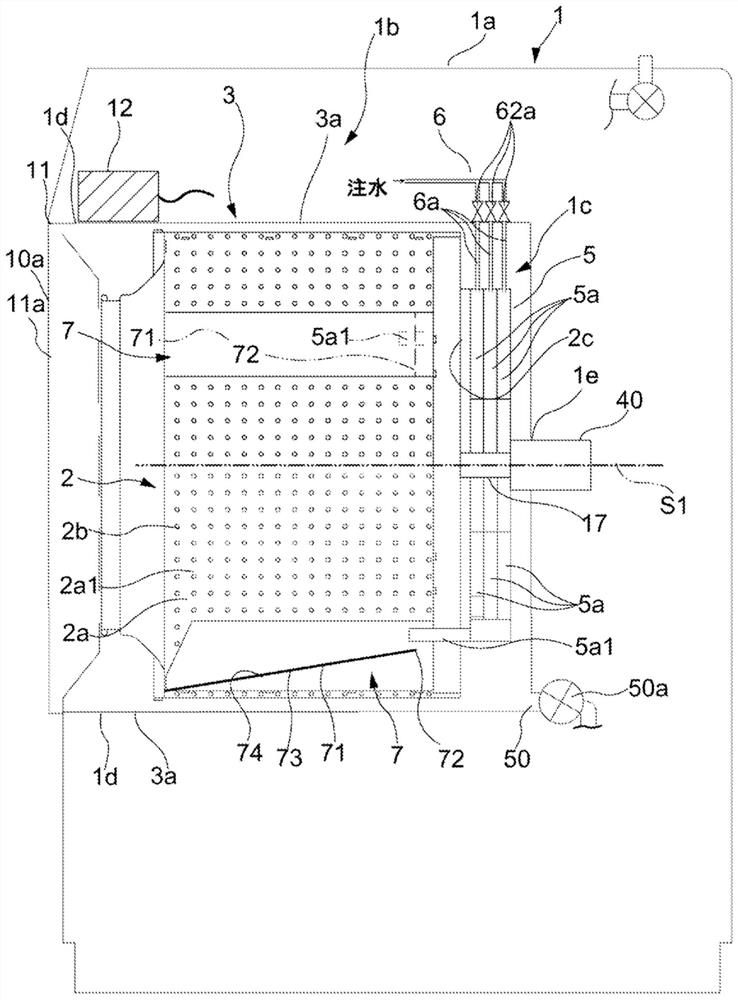

[0037] figure 1 It is sectional drawing which shows typically the structure of the washing machine 1 which concerns on this embodiment. figure 2 It is an operation explanatory diagram which shows the longitudinal cross section of the part of the washing machine 1 of this embodiment.

[0038] The washing machine 1 of the present embodiment is suitable for use in, for example, laundromats and households, and includes a washing machine body 1a; a washing tub 1b including an outer tub 3 and a drum 2 having an axis S1 extending substantially horizontally; and a water injection device 1c , has a water receiving unit 5 and a nozzle unit 6; a driving device 40; a control unit not shown.

[0039] figure 1 The shown washing machine main body 1a has a substantially rectangular parallelepiped shape. On the front surface 10a of the washing machine main body 1a, an opening 11 for taking and ...

no. 2 approach

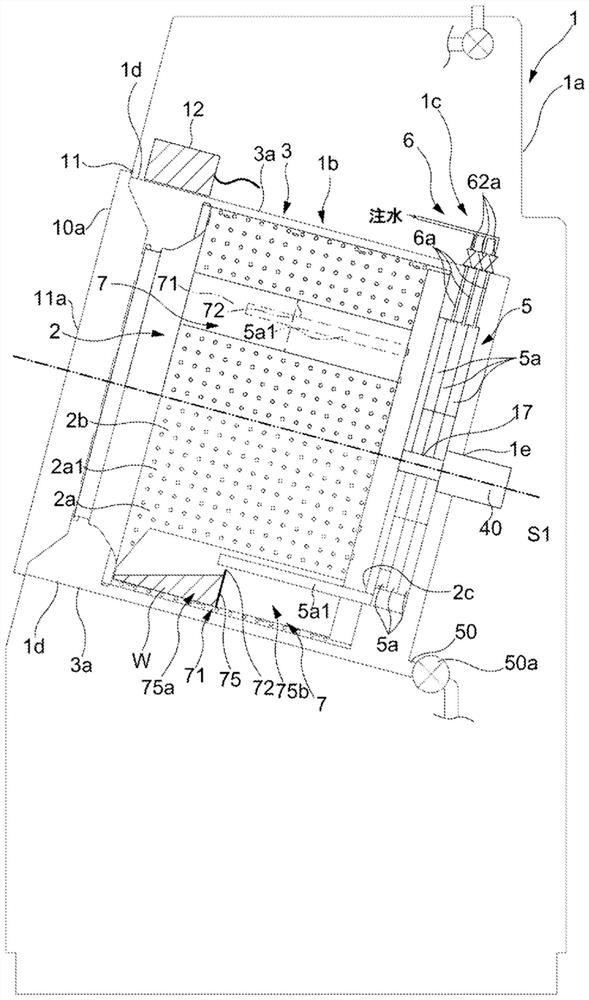

[0060] image 3 It is sectional drawing which shows typically the structure of the washing machine 1 which concerns on 2nd Embodiment of this invention. Figure 4 It is an operation explanatory diagram which shows the longitudinal cross section of the part of the washing machine 1 of this embodiment.

[0061] The washing machine 1 of the present embodiment includes a washing machine main body 1a; a washing tub 1b including an outer tub 3 and a drum 2 having an axis S1 extending substantially horizontally; a water injection device 1c including a water receiving unit 5 and a nozzle unit 6; and a driving device 40; A control unit (not shown) is the same as the above-described first embodiment in these points.

[0062] image 3 The washing machine main body 1a shown is configured in such a way that the front surface 10a thereof faces slightly upward, whereby the opening 11 for taking and placing laundry with respect to the drum 2 is formed obliquely upward, and the user can open...

no. 3 approach

[0069] The washing machine 1 of the third embodiment of the present invention, such as Figure 5 As shown, the axis S1 direction of the washing tub (drum) 1b extends in a substantially vertical direction, and the present invention is applied to a washing machine 1 called a so-called vertical fully automatic washing machine.

[0070] In such a vertical fully automatic washing machine 1 , a pulsator (stirring blade) 4 is rotatably arranged in the center of the bottom portion 2 c of the drum 2 . like Figure 5 As shown, the pulsator 4 is a normal pulsator having a substantially disk-shaped pulsator body and a plurality of fin portions formed on the upper surface of the pulsator body. Such a pulsator 4 agitates the wash water stored in the tub 3 to generate a water flow.

[0071] The drive device 40 such as Figure 5As shown, the drive shaft 17 extending toward the bottom 2c of the drum 2 is rotated by a motor (not shown) as the main body to provide driving force to the drum 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com