Frequency sweep and frequency following control method for frequency of ultrasonic welding power source

A technology of ultrasonic welding and power frequency, applied in the direction of output power conversion devices, electrical components, high-efficiency power electronics conversion, etc., can solve the problems of reducing work efficiency and exacerbating the loss of transducers, and achieves simple circuits, high speed and low cost. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

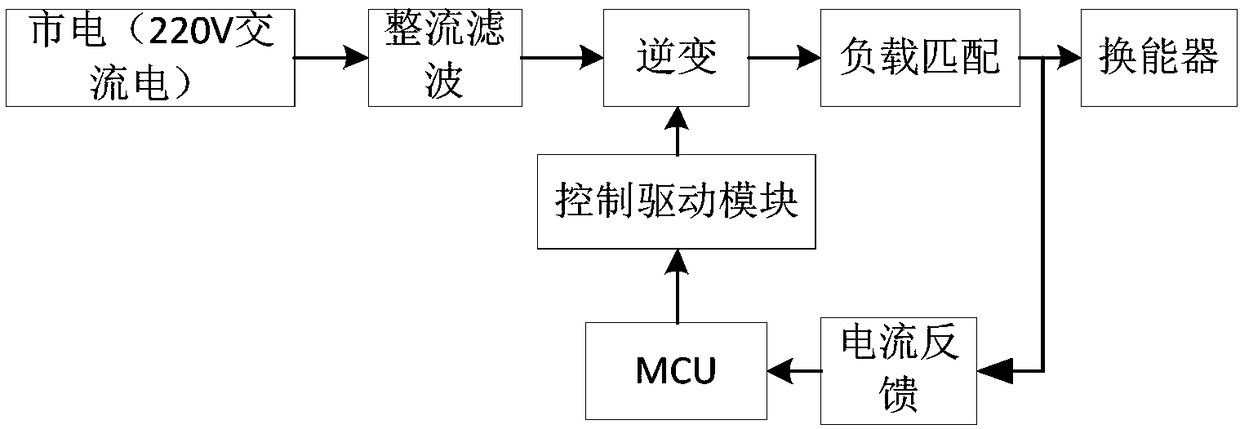

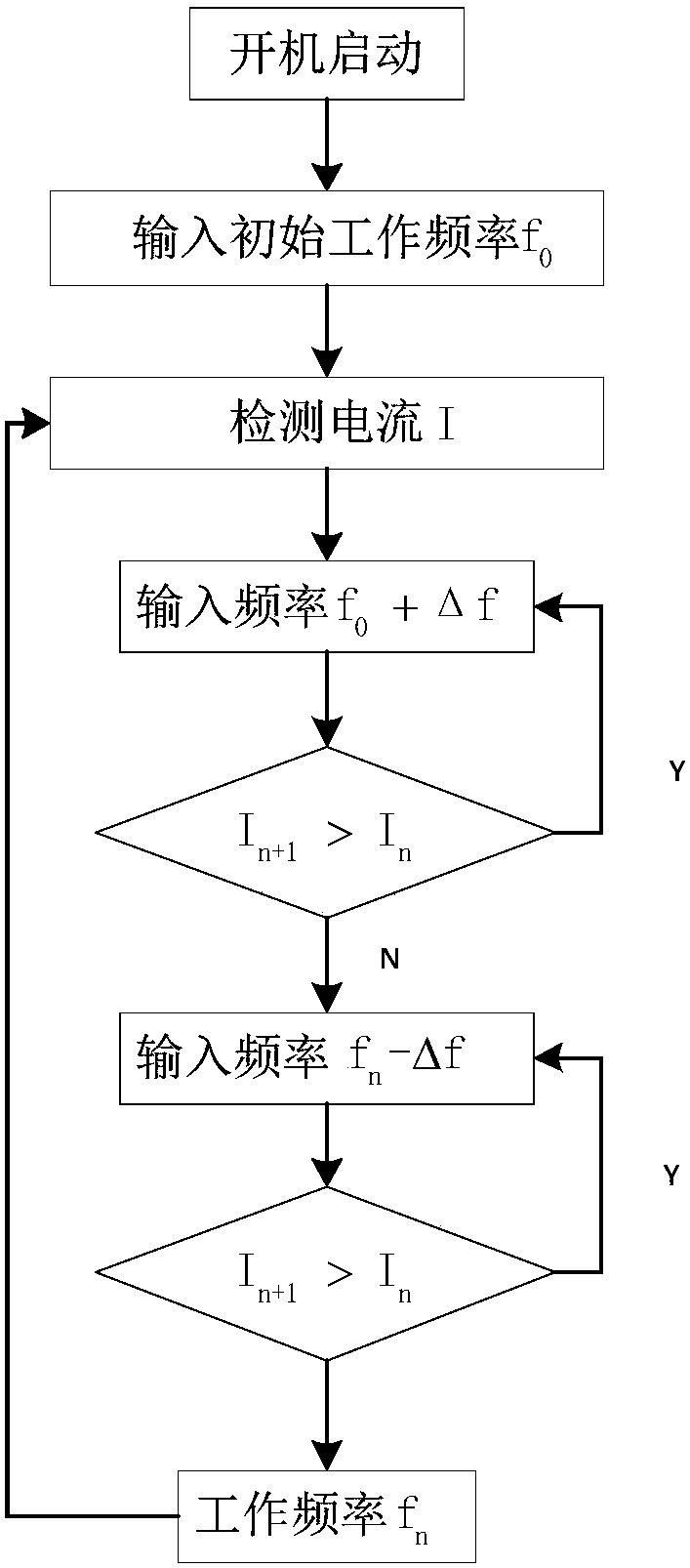

[0018] A frequency sweeping frequency tracking control method for an ultrasonic welding power supply frequency, comprising the following steps:

[0019] Step 1: After turning on the ultrasonic generator, the MCU controller controls the inverter to output a certain initial operating frequency through the drive controller;

[0020] Step 2: Detect the working current in the ultrasonic system; the frequency sweeping mode is that the MCU controller controls the inverter output frequency to be f 0 +Δf;

[0021] Step 3: Detect the working current in the ultrasonic system, if the working current in the ultrasonic system increases, it means f 0 is not the resonance frequency of the ultrasonic system, continue to increase the output frequency f of the inverter according to a certain step size 0 +Δf; if the operating current in the ultrasonic system decreases when the output frequency of the transducer is increased, the output frequency of the control inverter becomes f 0 -Δf, if the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com