Regenerated aluminum ash series artificial floor heating composite brick and production method thereof

A technology of recycled aluminum and composite bricks, which is applied in the field of artificial composite bricks and boards, can solve the problems of polluting the environment and the lack of comprehensive utilization of useful components, and achieve the effects of reducing emissions and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

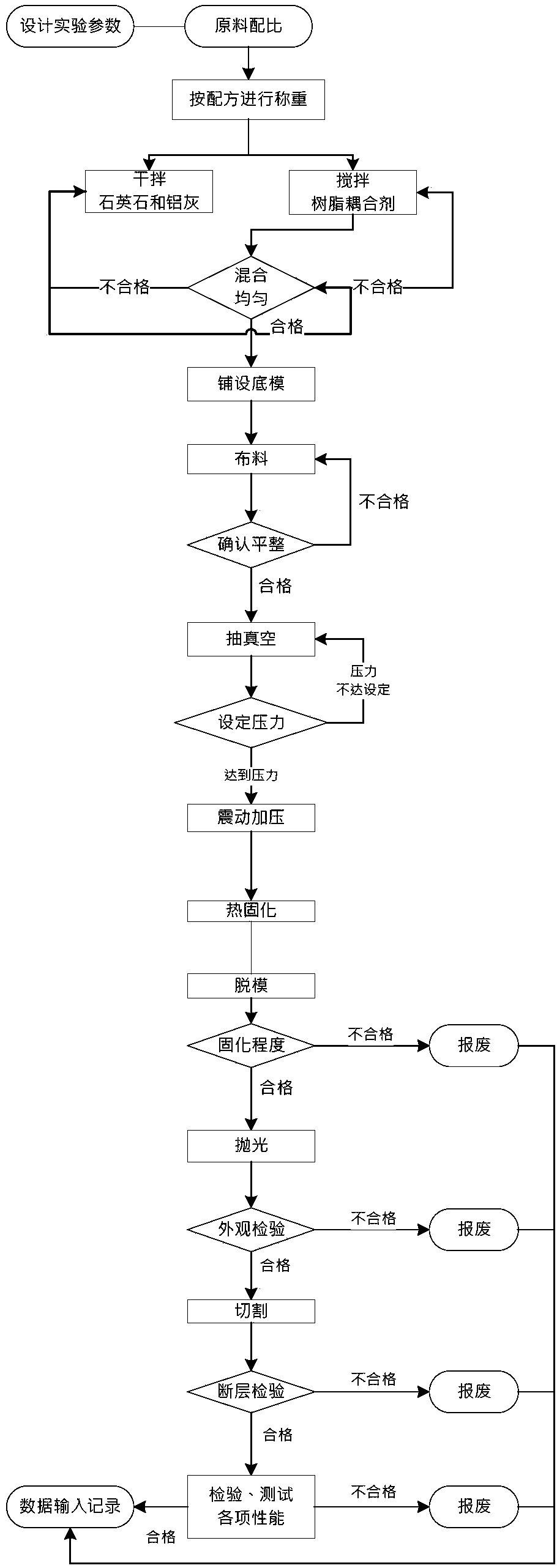

Method used

Image

Examples

Embodiment 1

[0043] A regenerated aluminum ash-based artificial floor heating composite brick of the present invention, the composite brick mainly includes regenerated aluminum ash, recycled aluminum ash, quartz powder, quartz sand, resin, curing agent, reactant, and silane coupling agent; Wherein the regenerated aluminum dust collection ash accounts for 5% of the mass percentage, the regenerated aluminum ash accounts for the 32% of the mass percentage, the quartz powder accounts for 4% of the mass percentage, and the particle diameter is 10 mesh quartz sand I accounts for 15% of the mass percentage, and the particle diameter is The 80-mesh quartz sand II accounts for 14% of the mass percentage, the 100-mesh quartz sand III accounts for 13% of the mass percentage, the resin accounts for 15% of the mass percentage, the curing agent accounts for 0.250% of the mass percentage, and the reactant accounts for 10% of the mass percentage. 0.25% and the silane coupling agent accounts for 1.5% of the...

Embodiment 2

[0071] A regenerated aluminum ash-based artificial floor heating composite brick of the present invention, the composite brick mainly includes regenerated aluminum ash, recycled aluminum ash, quartz powder, quartz sand, resin, curing agent, reactant, and silane coupling agent; Wherein the regenerated aluminum dust collection ash accounts for 3% of the mass percentage, the regenerated aluminum ash accounts for the 30% of the mass percentage, the quartz powder accounts for 2% of the mass percentage, and the particle diameter is that 15 purpose quartz sand 1 accounts for 17% of the mass percentage, and the particle diameter is The 70-mesh quartz sand II accounts for 16% of the mass percentage, the 200-mesh quartz sand III accounts for 15% of the mass percentage, the resin accounts for 15% of the mass percentage, the curing agent accounts for 0.250% of the mass percentage, and the reactant accounts for 15% of the mass percentage. 0.25% and the silane coupling agent accounts for 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com