Plastic sealing method for solving problem of plastic sealing mold flow and widening wafer width

A wafer and problem technology, applied in the field of plastic packaging to solve the problem of mold flow in plastic packaging and widen the width of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

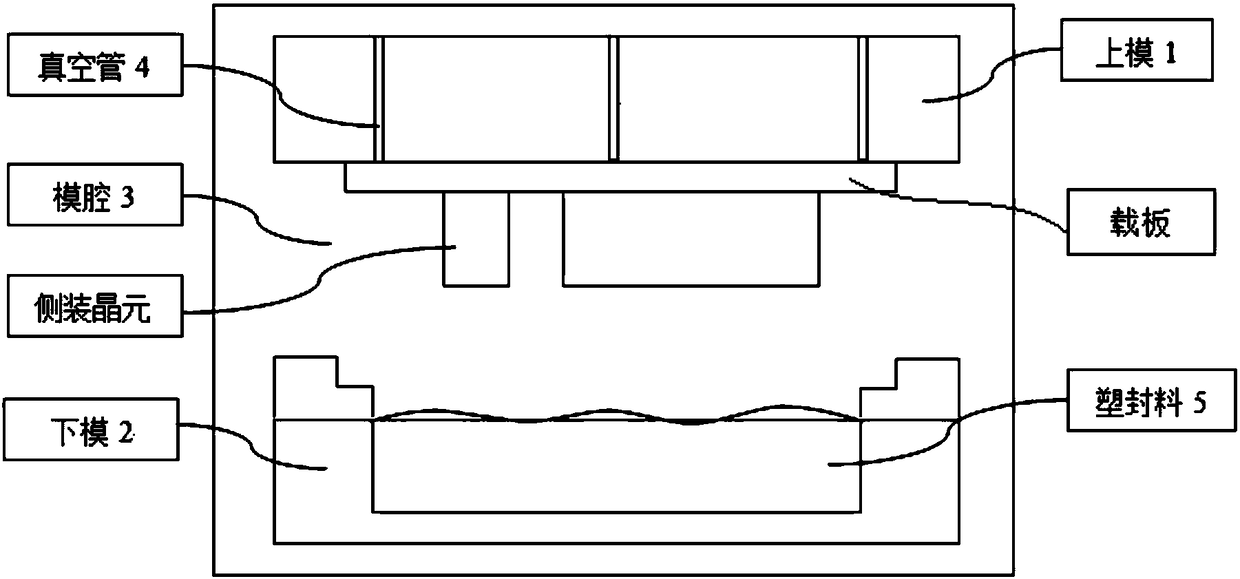

[0039] A plastic packaging method to solve the mold flow problem of plastic packaging and widen the width of wafers, such as figure 1 as shown, figure 1 It is a schematic flow chart of the method of the present invention. The method includes the following steps.

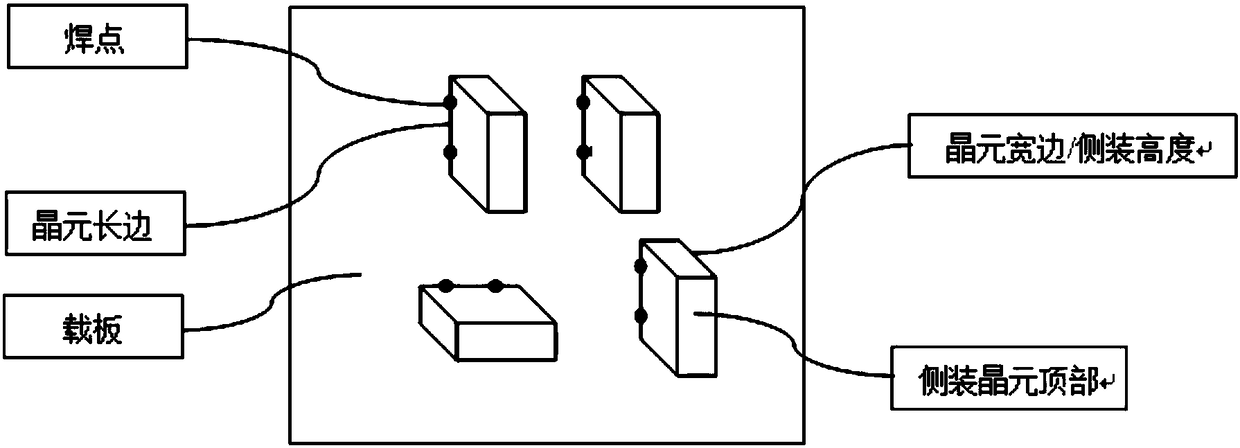

[0040] Step S1, designing the wafer circuit, and side-mounting the wafer and the carrier board.

[0041] image 3 It is a schematic diagram of floor mount plastic package of the present invention. like image 3 As shown, the wafer circuit design adopts one of single-sided circuit design or double-sided circuit design. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com