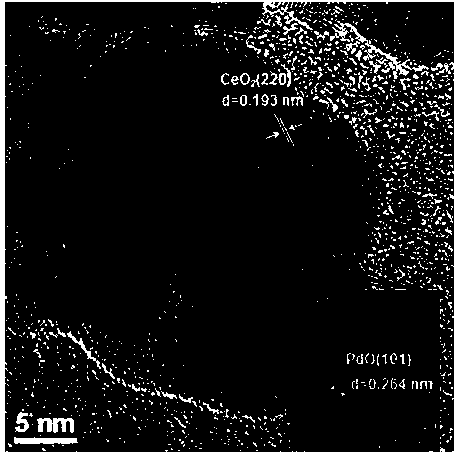

Spherical catalyst with Pd wrapped by cerium dioxide and preparation method thereof

A technology of ceria and catalyst, which is applied in the field of ceria-wrapped Pd spherical catalyst and its preparation, can solve the problems of limited scale industrial application, high Pd content, complex control conditions, etc., and achieve excellent activity and stability, The effect of increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

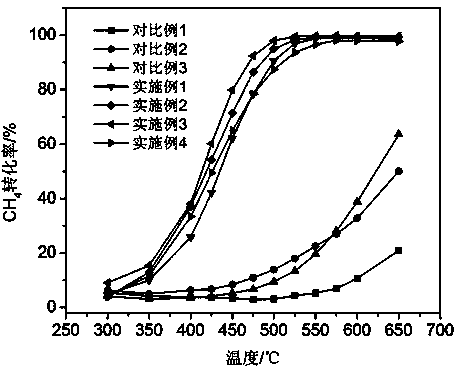

Examples

Embodiment 1

[0030] At room temperature, dissolve 0.56 g PVP and 1.74 g citric acid in a mixture of water: absolute ethanol = 2:1, then add 17.1 mg palladium nitrate solution containing Pd, stir for 10 min, add 4.2 g nitric acid After adding cerium, 0.6 g urea, and adding 6 mL hydrogen peroxide, stirring for another 20 min, put the resulting solution in a polytetrafluoroethylene bottle, and place it in an oven at a temperature of 2 ℃ / min to 120 ℃ for 12 h. The resulting product is used Wash with deionized water and absolute ethanol, centrifuge, and dry at 60 ℃ for 7 hours; the resulting product is placed in a muffle furnace and raised to 400 ℃ at a rate of 0.5 ℃ / min. After 4 hours of heat preservation, the product is heated at 0.5 ℃ / min Continue to heat up to 600 ℃, calcinate for 2 h, and cool down naturally to obtain the desired catalyst.

Embodiment 2

[0032] At room temperature, dissolve 0.42 g PVP and 1.74 g citric acid in a mixed solution of water: anhydrous ethanol=3:1, then add a palladium nitrate solution containing 4.3 mg of Pd, stir for 10 min, add 3.2 g nitric acid Cerium, 0.6 g urea, stir for another 20 minutes, put the resulting solution in a polytetrafluoroethylene bottle, place it in an oven at 2 ℃ / min to 80 ℃ for 1 h, then program to 120 ℃ for 24 h, The resultant product was washed with deionized water and absolute ethanol, centrifuged, and dried at 60 ℃ for 7 h; the resultant product was placed in a muffle furnace and raised to 400 ℃ at a rate of 1 ℃ / min. After 4 hours of heat preservation, Continue to heat up to 600 ℃ at a rate of 1 ℃ / min, calcinate for 2 h, and cool down naturally to obtain the desired catalyst.

Embodiment 3

[0034] At room temperature, dissolve 0.42 g PVP and 1.23 g citric acid in a mixed solution of water: absolute ethanol = 4:1, then add a palladium nitrate solution containing 8.8 mg of Pd, stir for 10 min, add 2.1 g nitric acid Cerium, 0.3 g of urea, and 3 mL of hydrogen peroxide were added, and then stirred for another 20 minutes. The resulting solution was placed in a polytetrafluoroethylene bottle and placed in an oven at a rate of 2 ℃ / min to 80 ℃. After reaction for 2 h, the program The temperature was raised to 120 ℃ and reacted for 24 hours. The product was washed with deionized water and absolute ethanol, centrifuged, and dried at 60 ℃ for 7 h; the product was placed in a muffle furnace and heated to 400 ℃ at a rate of 1 ℃ / min After the heat preservation treatment for 4 h, continue to heat up to 600 ℃ at a rate of 1 ℃ / min, calcinate for 2 h, and naturally lower the temperature to obtain the desired catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com