Unloading pre-charging valve structure of hydraulic machine

A hydraulic press and pre-charging technology, which is applied to mechanical equipment, fluid pressure actuating devices, servo motor components, etc., can solve the problems of slow filling speed of disc-shaped pre-charging valve, large volume of pressure-holding cylinder, affecting production efficiency, etc. Achieve the effect of low mechanical strength requirements, improved pressure holding performance, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

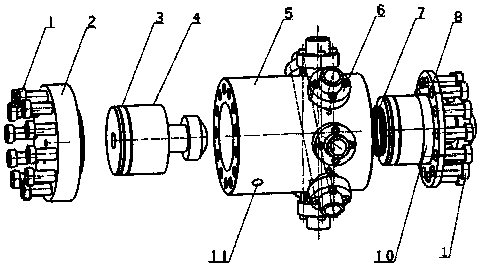

[0019] Such as figure 1 , 2 Shown: a hydraulic machine unloading pre-fill valve structure, which includes the main valve core 4, the limit spring 7, the main valve port 10, the upper end cover 2, the lower end cover 8 and the main valve 5, the upper end cover is fixed on the upper end of the main valve, The main valve core is assembled in the main valve, and the lower part of the main valve core controls the circulation and disconnection of the main valve port oil circuit through the limit spring, and the lower end cover is fixed on the lower end of the main valve.

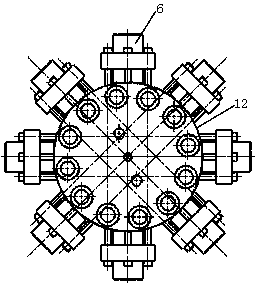

[0020] The area of the upper end surface of the main spool is larger than the area of the lower end surface of the main spool, the outer ring of the main spool is provided with a sealing groove 3, the outside of the main valve is provided with a control oil port 11 and a ring of oil inlets 6, and there are eight oil inlets , the upper end cover is fixed on the upper end of the main valve by fixing bolts 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com