Nitrogen doped fluorescent carbon quantum dot and preparation method thereof

A technology of carbon quantum dots and nitrogen doping, applied in fluorescence/phosphorescence, chemical instruments and methods, nano-optics, etc., can solve the problems of high cost and complex processing, and achieve low cost, good biocompatibility, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

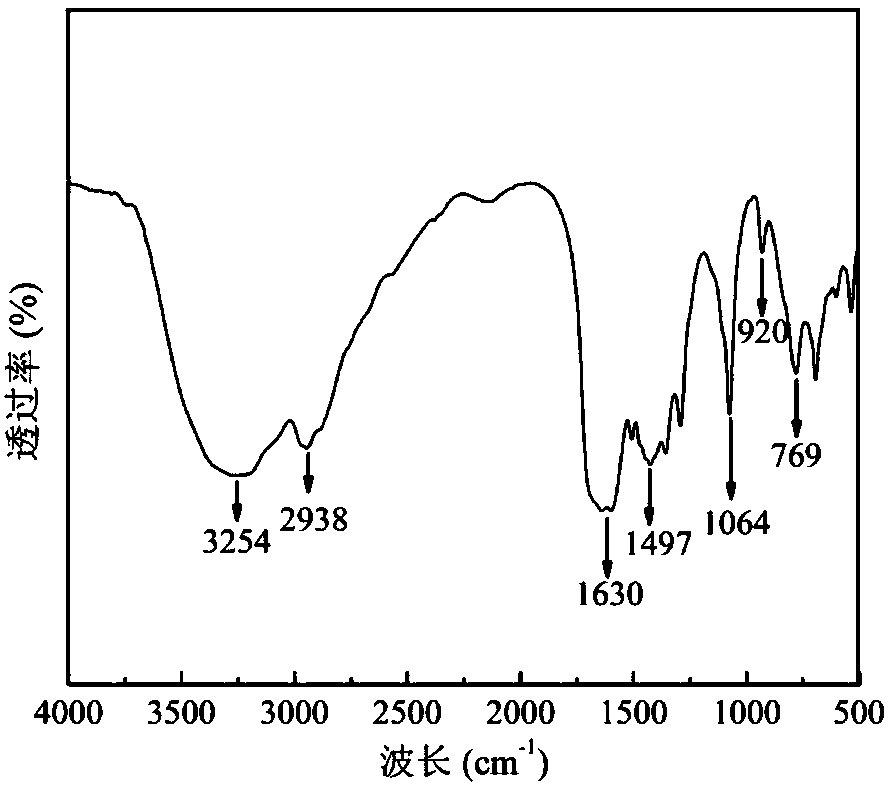

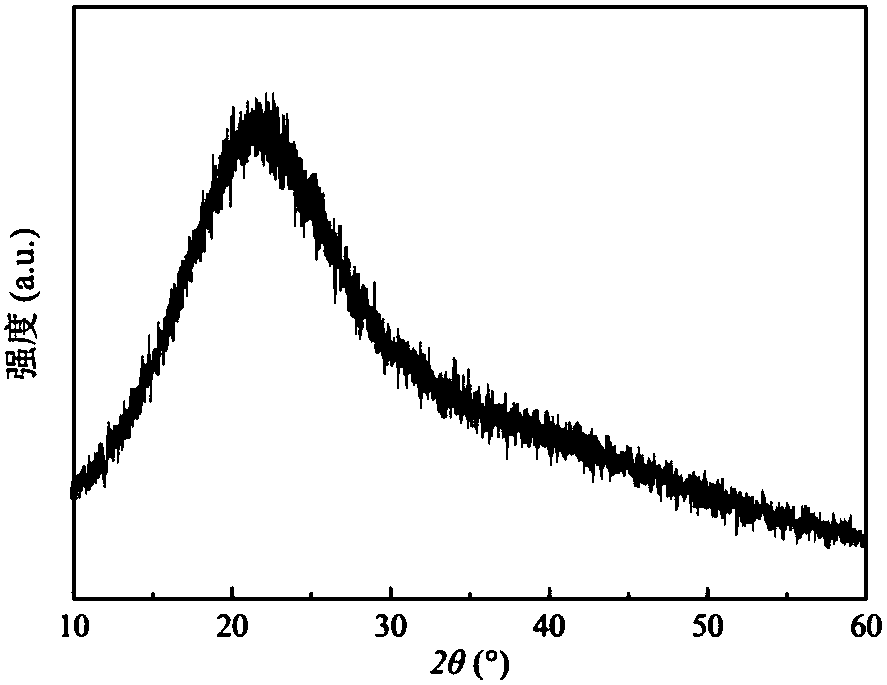

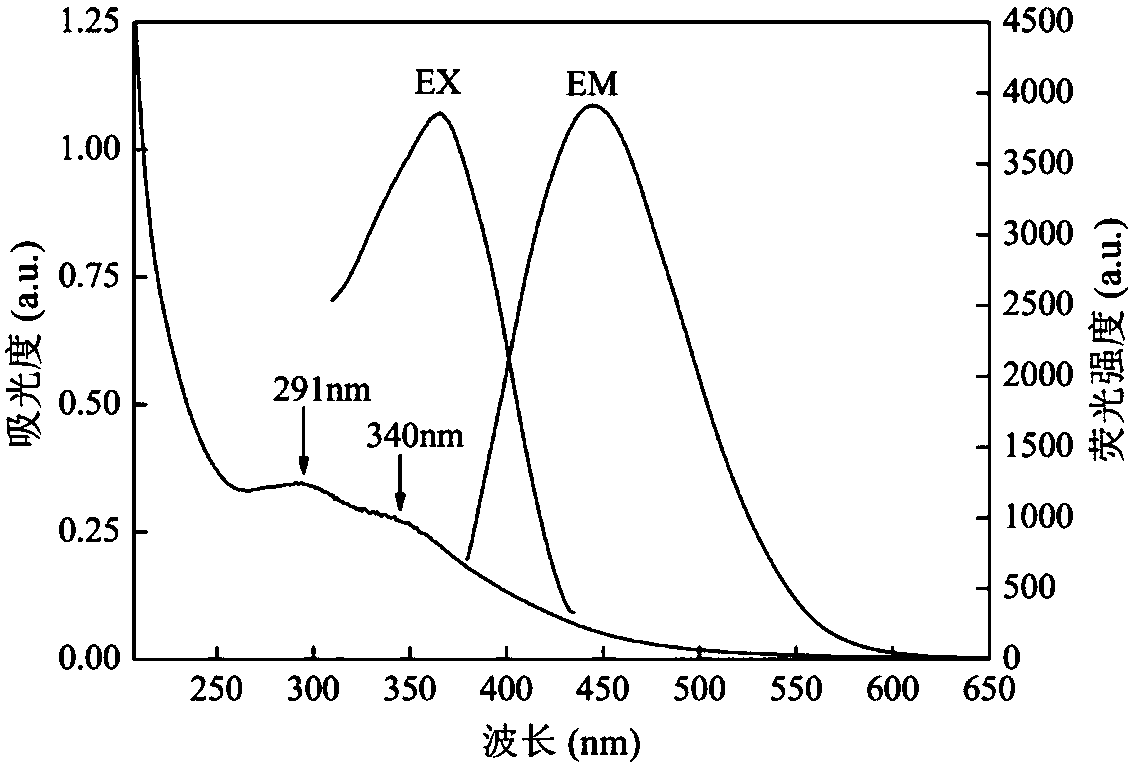

[0045] Weigh 2g of carboxymethylcellulose (molecular weight: 90000, purchased from Aladdin Company), fully dissolve in 40mL of ultrapure water under magnetic stirring at room temperature, add 1.5g of ethylenediamine to the carboxymethylcellulose solution medium (the mass ratio of ethylenediamine to carboxymethyl cellulose is 0.75), after the above two raw materials are mixed evenly, add ultrapure water to make up to 50mL to obtain a transparent light yellow solution; then transfer the above solution Put it into a PPL-lined stainless steel high-pressure reaction kettle, seal it, place it in an oil bath, and heat it for 36 hours at a controlled reaction temperature of 220°C; after the reaction is completed, after the reaction kettle is cooled to room temperature, a dark brown reaction solution is obtained , ultrasonically disperse for 20min under the condition that the power of the ultrasonic cell pulverizer is 100W, ultrasonically disperse for 2s and stop for 3s, centrifuge for ...

Embodiment 2

[0052] Referring to Example 1, the difference from Example 1 is that the mass ratio of ethylenediamine to carboxymethylcellulose is 0.15. The fluorescence quantum yield of nitrogen-doped carbon quantum dots prepared under this condition is 13.13%.

Embodiment 3

[0054] Referring to Example 1, the difference from Example 1 is that the mass ratio of ethylenediamine to carboxymethylcellulose is 0.30. The fluorescence quantum yield of nitrogen-doped carbon quantum dots prepared under this condition is 14.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com