A kind of hydroxy copper fluoride nano sheet and its synthesis method

A technology of copper hydroxyfluoride and nanosheets, applied in copper halide and other directions, can solve the problems of rare reports on the preparation and application of copper hydroxyfluoride, difficulty of high-purity CuOHF, high price, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 The best overall process for preparing CuOHF nanosheets.

[0032] Using copper nitrate, hexamethyltetramine (HMT), sodium fluoride (NaF), and deionized water as raw materials, first dissolve 0.362g of copper nitrate and 0.210g of HMT in 15ml of deionized water, and stir at room temperature 10min, then add 0.315g of NaF and continue stirring at room temperature for 15min. After the stirring is completed, pour the mixed solution into a polytetrafluoroethylene liner with a volume of about 20ml, and then put it into a stainless steel autoclave and seal it. Heat up to 95°C at a heating rate of 5°C / min and keep it warm for 2 hours. After the reaction is completed, the autoclave is naturally cooled to room temperature, and the reaction product is centrifugally washed with deionized water for 3 to 4 times in order to obtain a high-purity sample, and then The reaction product was dried at 65°C for 2 hours to obtain a light green powder sample.

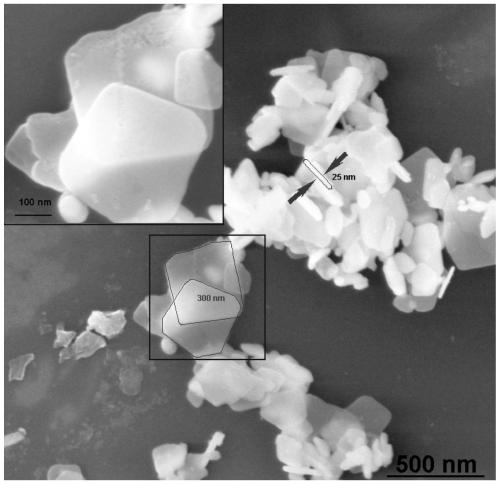

[0033] figure 1 Give...

Embodiment 2

[0034] Example 2 The whole process of preparing CuOHF nanosheets.

[0035] With copper nitrate, HMT, sodium fluoride, deionized water as raw material (each raw material consumption is the same as embodiment 1), at first copper nitrate and HMT are dissolved in the deionized water of 15ml, stir 10min at room temperature, add NaF then, in Stirring was continued for 15 min at room temperature. After the stirring is completed, pour the mixed solution into a polytetrafluoroethylene liner with a volume of about 20ml, and then put it into a stainless steel autoclave and seal it. Heat to 95°C at a heating rate of 5°C / min and keep it warm for 6 hours. After the reaction is completed, the autoclave is naturally cooled to room temperature, and the reaction product is centrifugally washed with deionized water for 3 to 4 times in order to obtain a high-purity sample, and then The reaction product was dried at 65°C for 2 hours to obtain a light green powder sample.

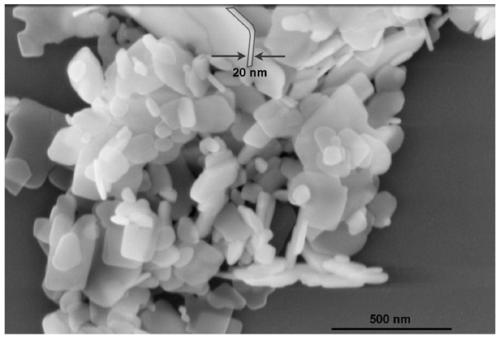

[0036] Image 6 Given...

Embodiment 3

[0037] Example 3 The whole process of preparing CuOHF nanosheets.

[0038]With copper nitrate, HMT, sodium fluoride, deionized water as raw materials (the same amount of raw materials as in Example 1), first copper nitrate and HMT were dissolved in 15ml of deionized water, stirred at room temperature for 10min, then added NaF at room temperature Stirring was continued for 15 min. After the stirring is completed, pour the mixed solution into a polytetrafluoroethylene liner with a volume of about 20ml, and then put it into a stainless steel autoclave and seal it. Heat up to 95°C at a heating rate of 5°C / min and keep it warm for 10 hours. After the reaction is completed, the autoclave is naturally cooled to room temperature, and the reaction product is centrifugally washed with deionized water for 3 to 4 times in order to obtain a high-purity sample, and then The reaction product was dried at 65°C for 2 hours to obtain a light green powder sample.

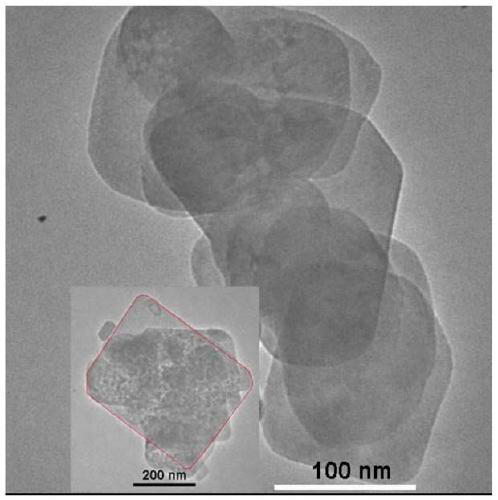

[0039] Figure 7 Given the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com