Lockable control shielding device for infrared receiver of assembly line

An infrared receiver and assembly line technology, applied to conveyor control devices, conveyors, packaging, etc., can solve problems such as production process disorder and safety accidents, and achieve the effect of avoiding misoperation and ensuring orderly and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

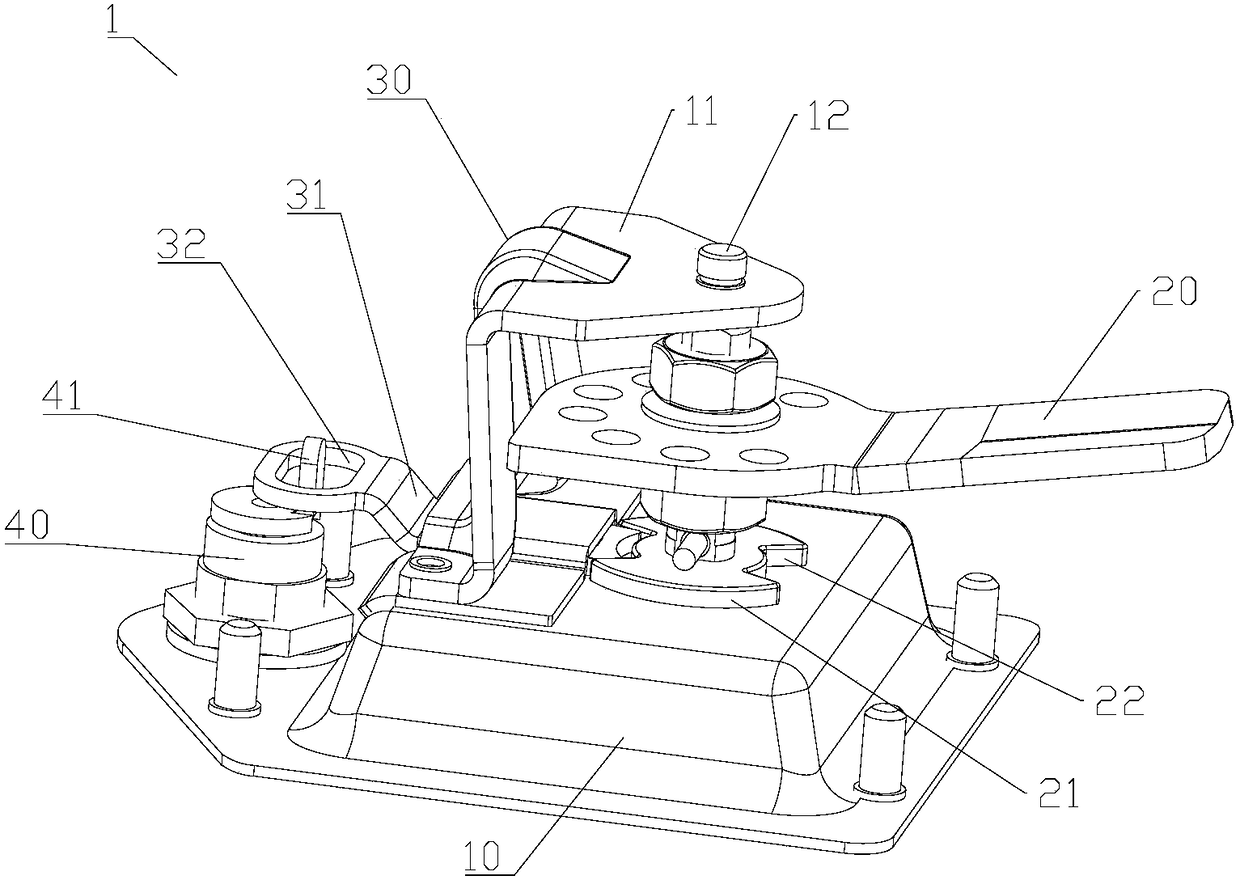

[0011] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

[0012] like figure 1 As shown, a lockable control shutter 1 for an assembly line infrared receiver includes a fixed base 10, a bracket 11 is arranged on the fixed base 10, a rotating shaft 12 is connected between the fixed base 10 and the support 11, and a rotating shaft 12 is fixedly connected with a The shielding piece 20 is also fixedly connected to a turntable 21 on the rotating shaft 12. The turntable 21 is provided with a pair of notches 22. One end is matched with the notch 22, the other end of the movable piece 31 is provided with a through hole 32, the fixed base 10 is rotatably provided with a lock cylinder 40, the lock cylinder 40 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com