Aluminum oxide production equipment management system

A technology of production equipment and management system, applied in office automation, data processing applications, instruments, etc., can solve the problems of difficult-to-produce equipment and equipment statistics, on-site point inspection provision, etc., to improve the work efficiency of maintenance personnel and prevent equipment accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention are clearly and completely described below.

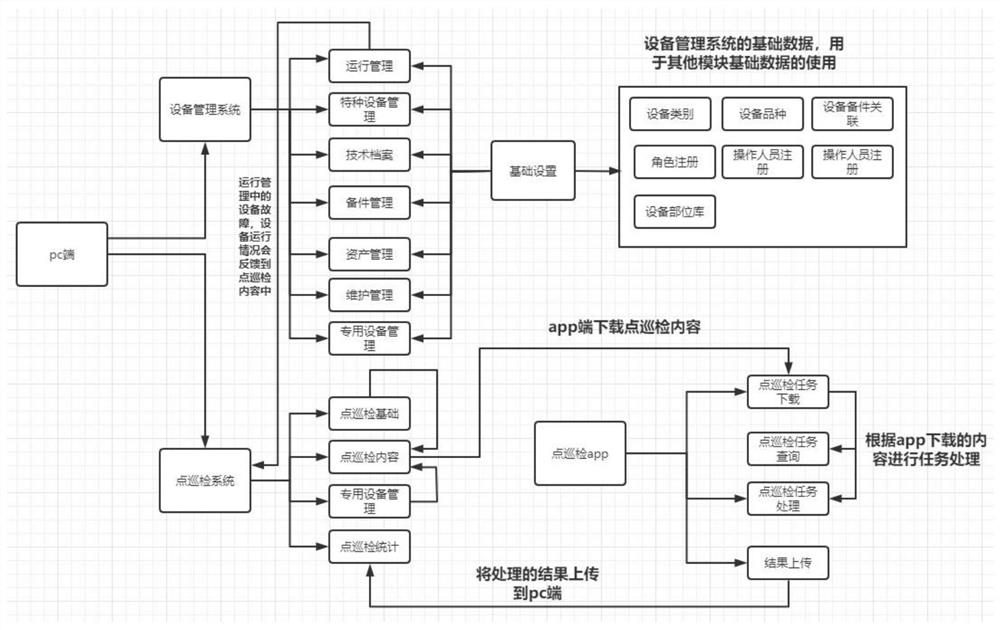

[0025] The present invention is implemented as follows: the equipment management system includes: asset management module, technical file management module, operation management module, maintenance management module, special equipment management module, whole process management of equipment failure, spare parts management module, basic management module, equipment files manage.

[0026] The equipment file management module is used to record and display the relevant information corresponding to the equipment of the whole plant. Personnel at all levels can check the relevant information of various equipment in the whole plant according to equipment classification, management department, user department, and subordinate department, including not only the equipment number , name, model, picture, manufacturer name, contact person, telephone number and other infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com