Multi-purpose rope pressing device for stepless rope winch

A technology of a rope pressing device and a rope winch, which is applied in the field of a multi-purpose rope pressing device of an infinite rope winch, can solve problems such as hidden dangers of major accidents, injury to personnel and equipment, etc., to prevent injury to people and equipment, ensure safety, and have a simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

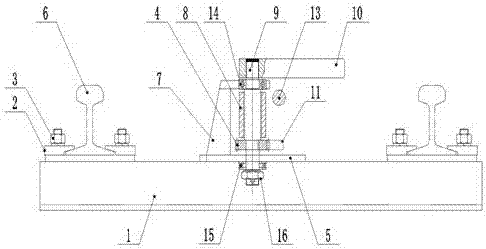

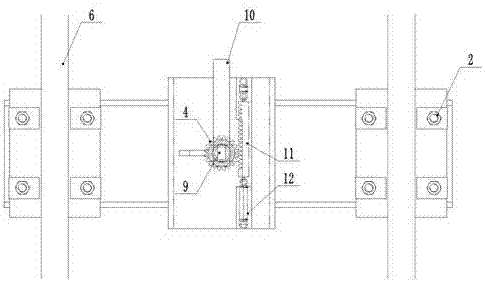

[0013] As shown in the figure, a multi-purpose rope-pressing device of a stepless rope winch includes an underframe 1, a wire rope 13 and a rope-pressing device, and the rope-pressing device is connected by a bolt 3 and a nut 16 on a fixing plate 5 on its bottom surface, Installed on the chassis 1, the steel wire rope 13 runs in the space below the rope pressing rod 10 of the rope pressing device, and the rope pressing device is composed of the rope pressing bar 10, the rotating shaft 9, the rotating shaft 9 fixing parts, the gear 4 and the transmission mechanism, The rotating shaft 9 is welded in the through hole of the rope pressing rod 10 to prevent the steel wire rope 13 from being thrown out of the groove to the outside of the track 6. The bottom end of the rotating shaft 9 is welded to the gear 4, and the rotating shaft 9 is fixed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com