Capsule machine convenient to collect capsules

A capsule machine, convenient technology, applied in chemical instruments and methods, solid separation, loading/unloading, etc., can solve the problems of wasting time and work efficiency, drug waste, drug efficacy reduction, etc., to improve efficiency, facilitate sorting, The effect of reducing the rotating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the technical means of the present invention, the creation of features, to achieve the purpose and effect readily apparent understanding, the following embodiment with reference to specific embodiments, further illustrate the present invention.

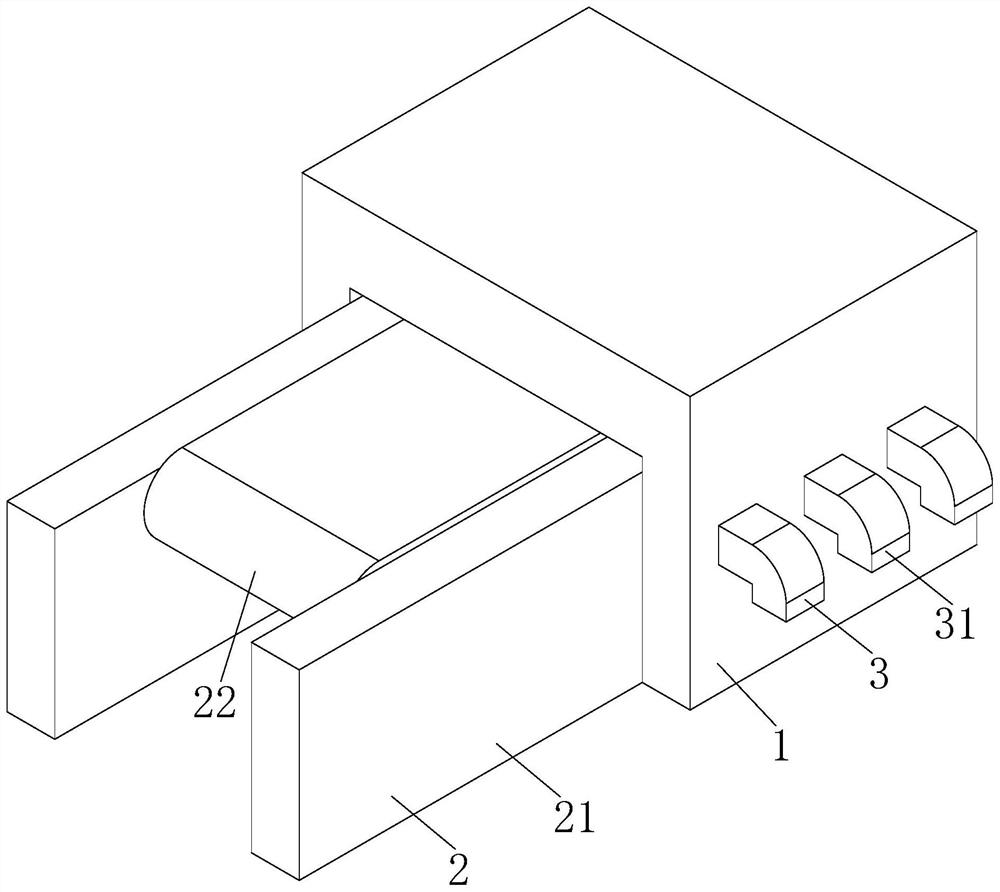

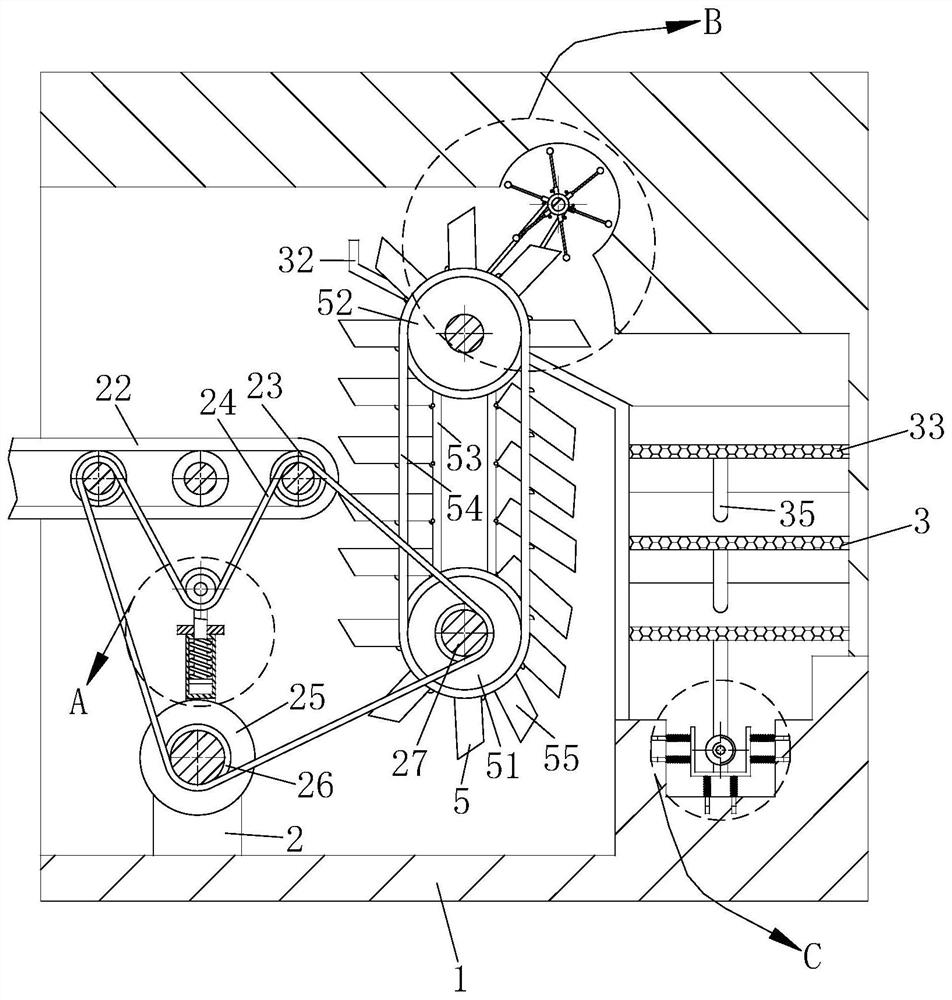

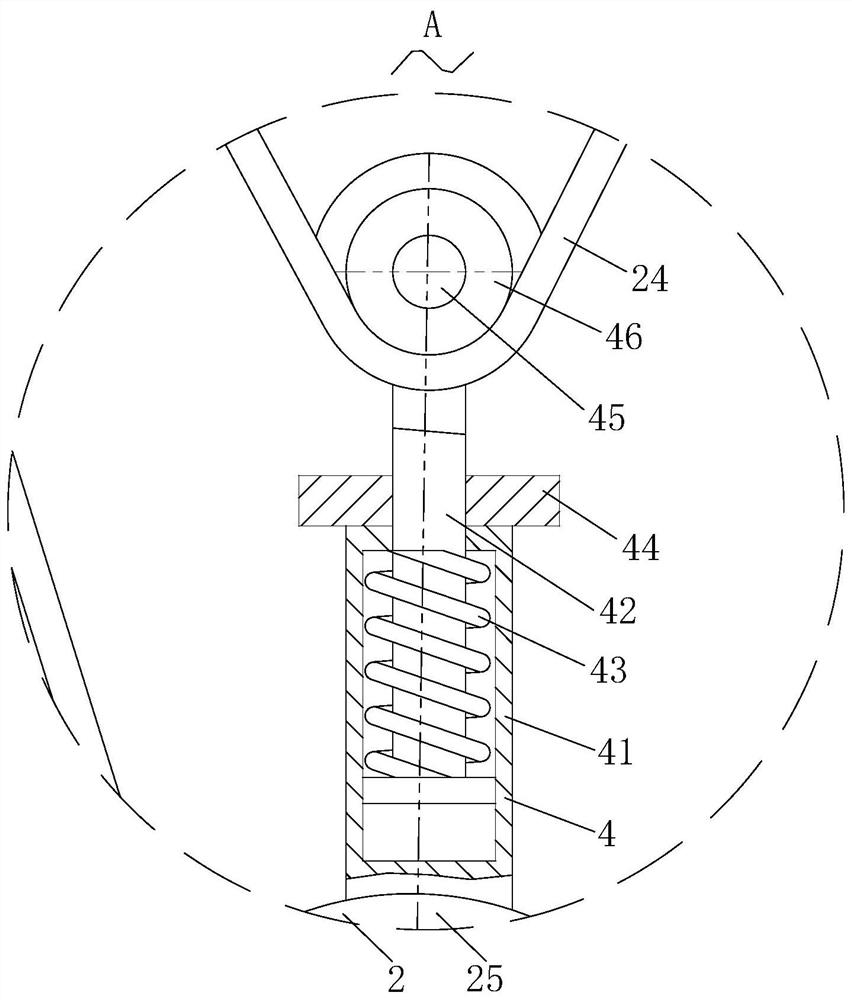

[0025] like Figure 1 - Figure 7Shown, to facilitate the collection of the capsule machine according to the present invention, comprises a body 1, a transmission mechanism 2, a filtering unit 3, the tensioning mechanism 4, the delivery mechanism 6 and tapping means 5 of the body 1 side is mounted for the operation of the transmission mechanism inside the main body part 1 powered internal 2, the screening body 1 is provided with means for entering the capsule according to the size of the collection filter 3, the interior of the transmission mechanism 2 for auxiliary components mounted inside the transmission mechanism 2 is kept in good working of the tensioning mechanism 4, the drive mechanism side of the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com