A uniform heating device suitable for planetary ball mill

A planetary ball mill, the technology of uniform heating, applied in the field of processing and grinding, can solve the problem that the material in the ball mill can not be heated, and achieve the effect of reliable heating and stable heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

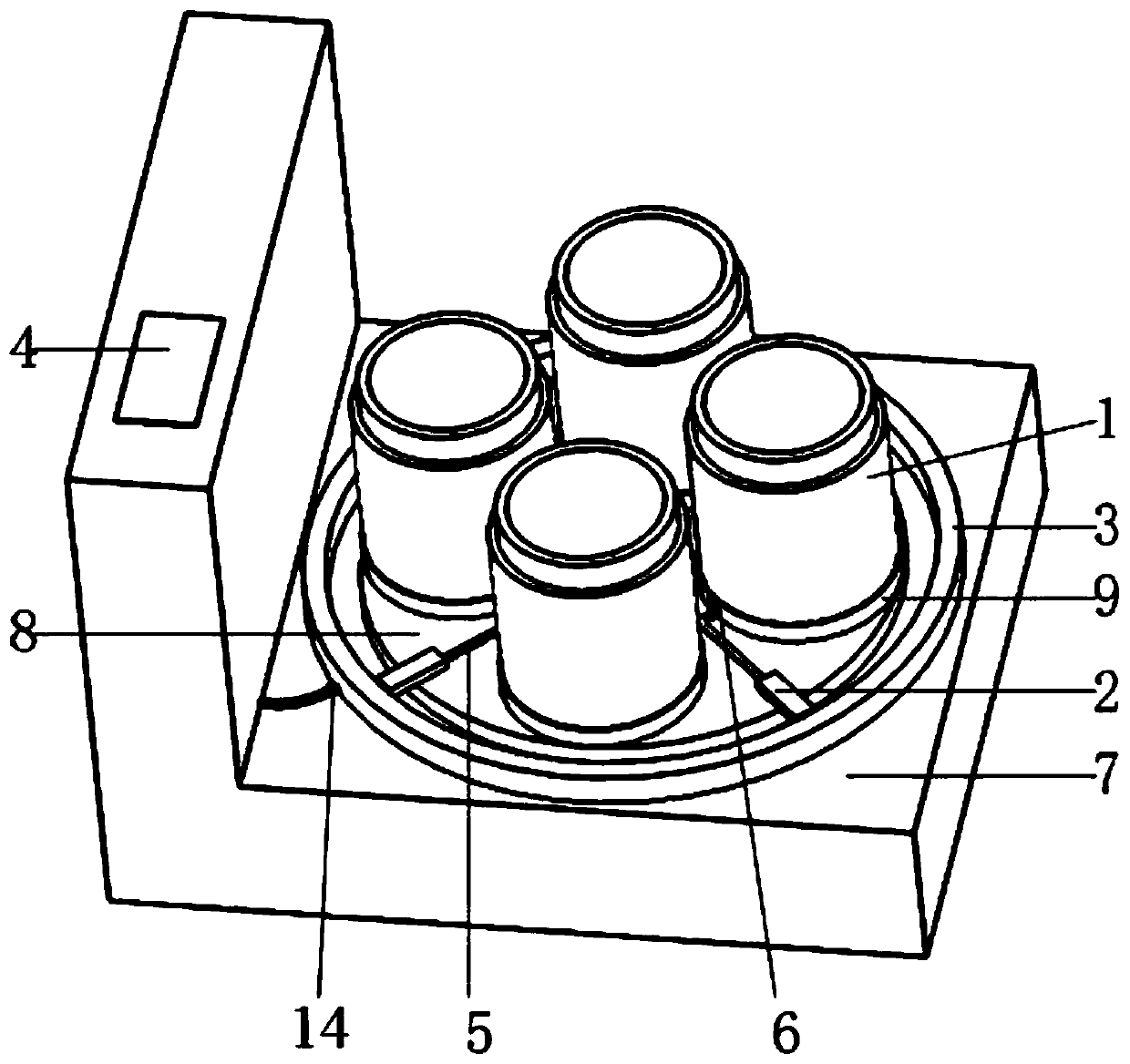

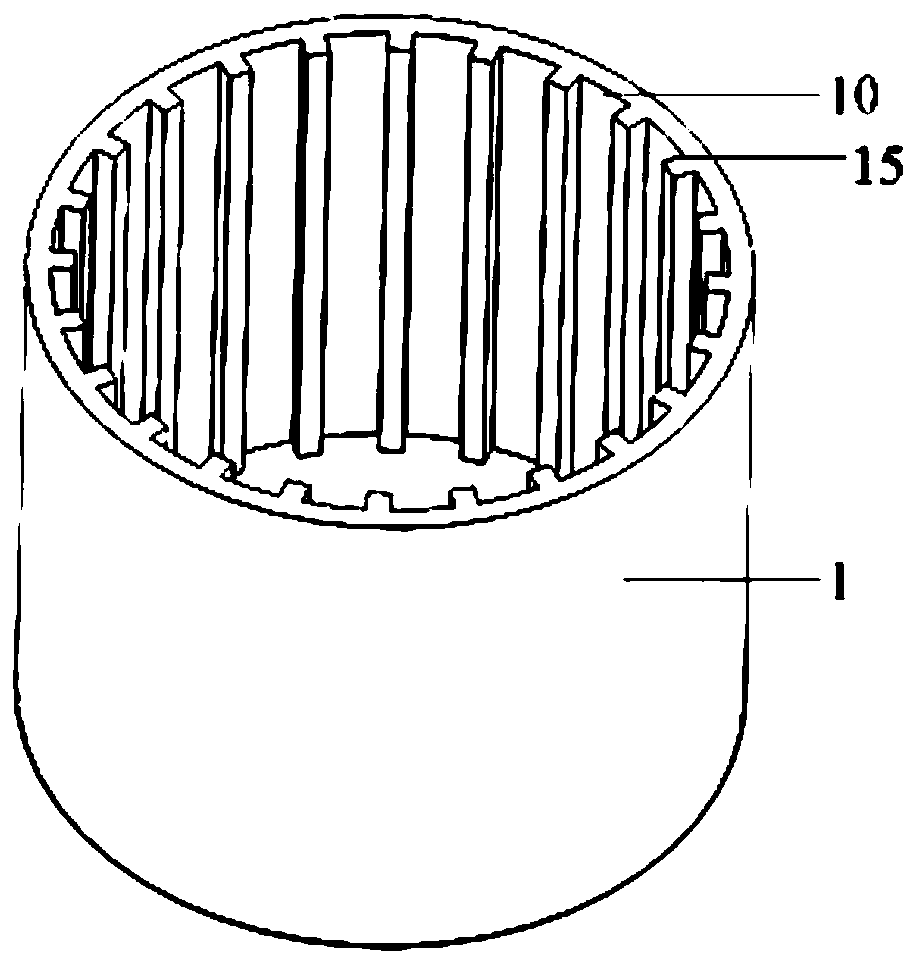

[0021] refer to figure 1 The shown uniform heating device suitable for a planetary ball mill includes a planetary ball mill body, the planetary ball mill body includes a base 7, a main turntable 8 arranged on the base 7, and a main turntable 8 arranged on the of four mill jars.

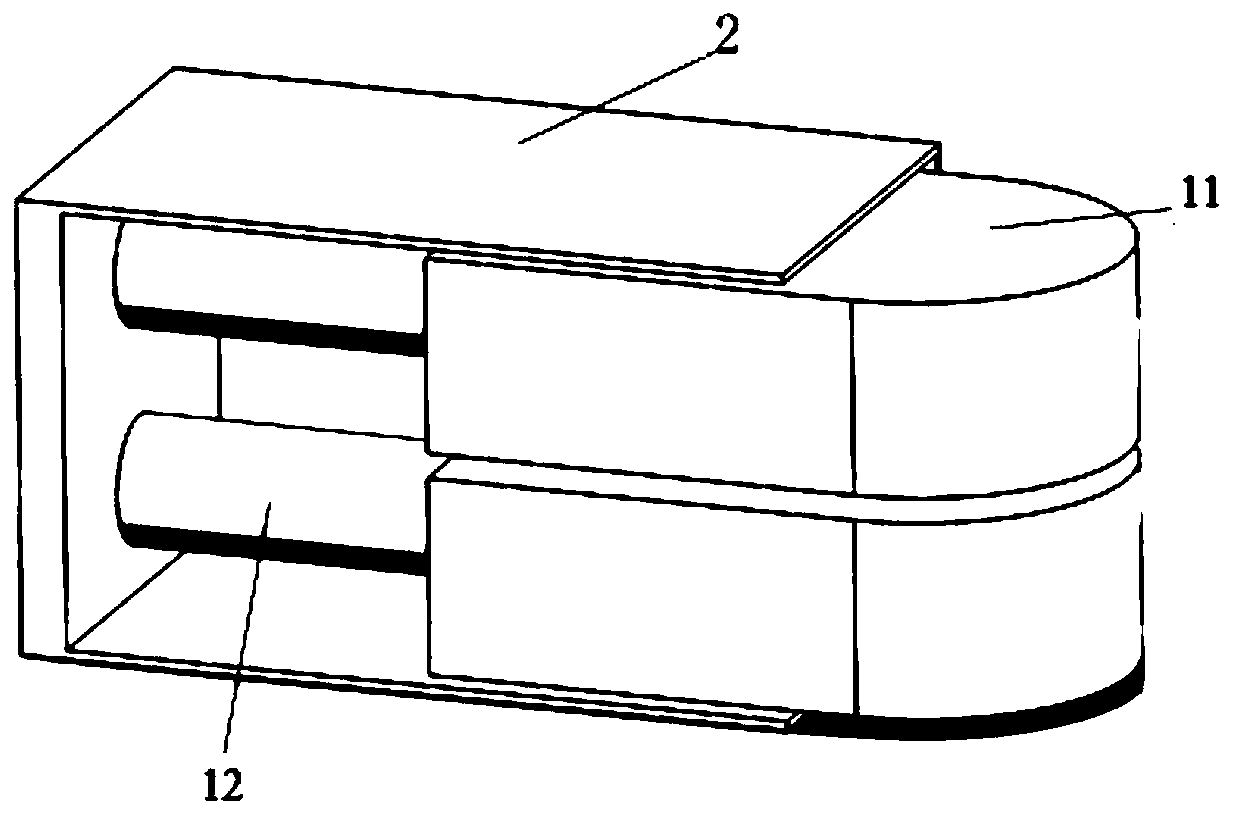

[0022] The base 7 is provided with an insulating slip ring 3 around the main turntable 8, referring to figure 2 As shown, the inner ring of the insulating slip ring 3 is provided with upper and lower layers of annular grooves 16 side by side, and each layer of annular grooves 16 is embedded with a ring-shaped conductive copper strip 13 . The thickness of the ring-shaped conductive copper strip 13 is slightly larger than the depth of the ring groove 16, and when it is in sliding contact with the carbon brush 11, friction between the carbon brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com