Composite material based on microwave heating, heat storage system and operation method thereof

A composite material and microwave heating technology, applied in the direction of heat exchange materials, heating methods, heating systems, etc., can solve the problems of reducing the service life of heat storage materials, reducing the proportion of heat storage materials, and the inability to transfer heat to the interior, etc., to achieve Low cost and rapid heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

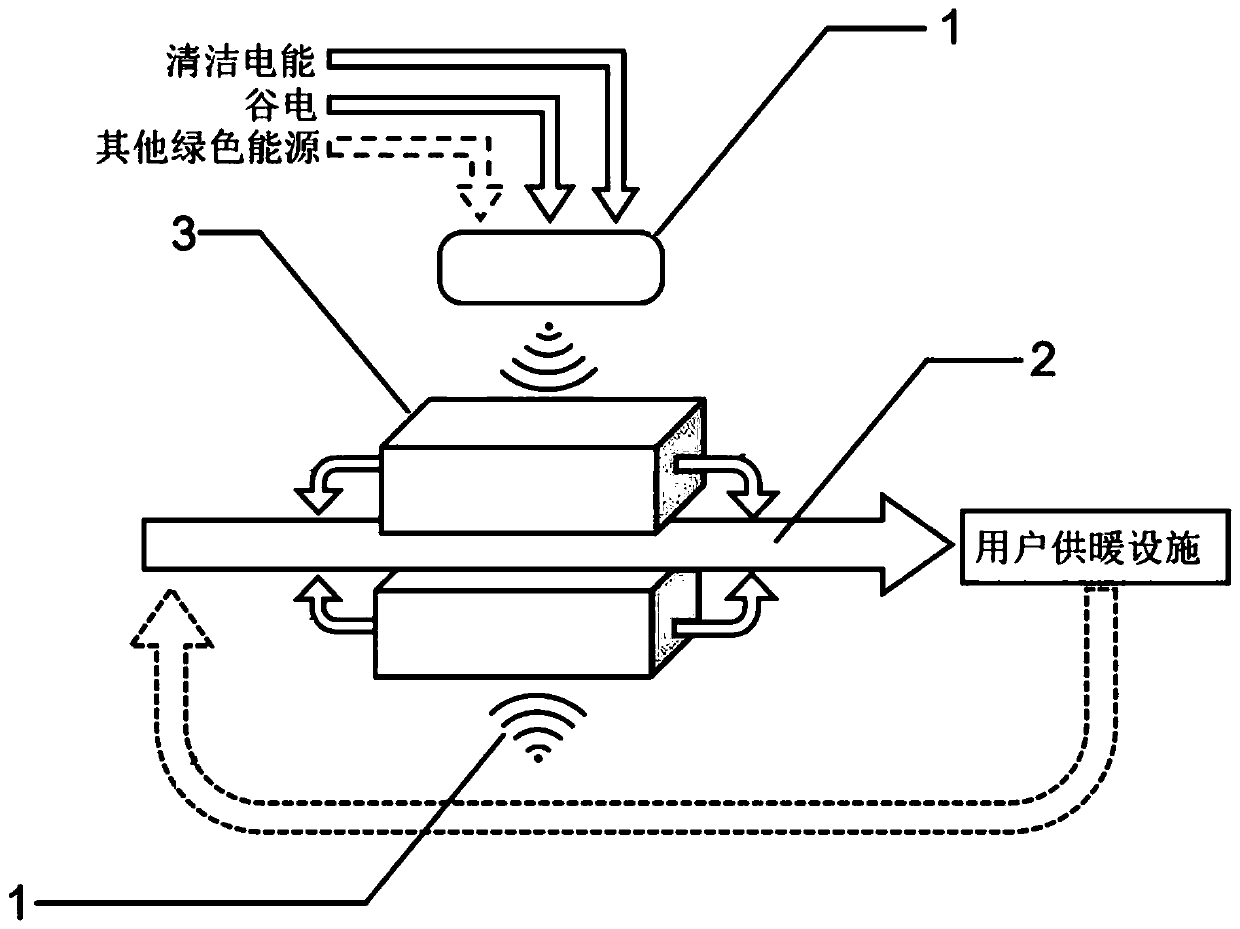

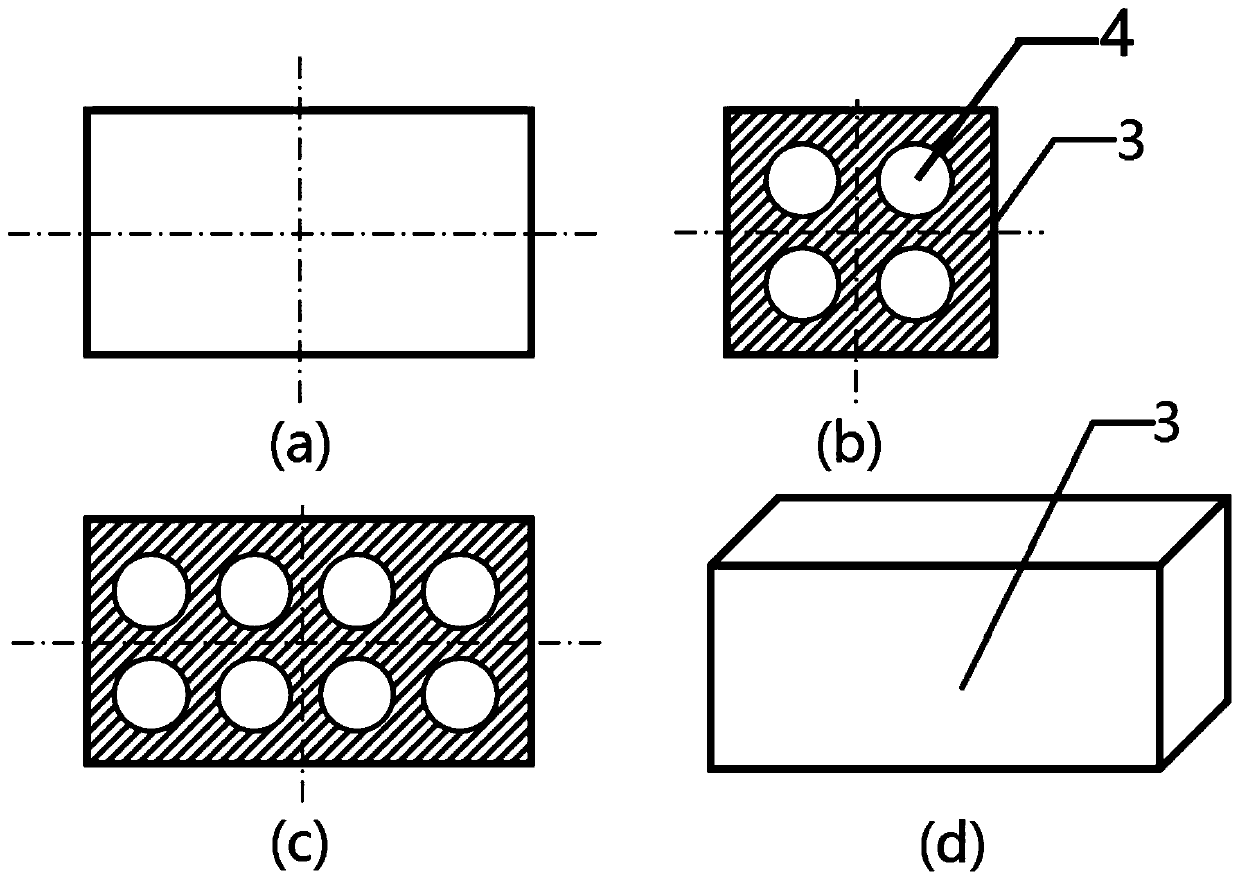

[0059] The heat storage system provided in this embodiment includes: a microwave generator and a wave-absorbing phase-change heat-storage brick, the microwave generator is arranged on one side of the wave-absorbing phase-change heat-storage brick, and the wave-absorbing phase-change heat-storage brick It is arranged on both sides of the circulating water for heating, and a composite material is arranged in the wave-absorbing phase-change heat storage brick. Wherein, the composite material is a paraffin / graphene composite material, and its preparation steps are as follows:

[0060] (1) Take 100g of paraffin and heat and melt it at a temperature higher than its melting point (60°C);

[0061] (2) Add 1.0 g of graphene, and mix well, so that the graphene is dispersed in the paraffin to obtain a paraffin / graphene composite material.

experiment example 1

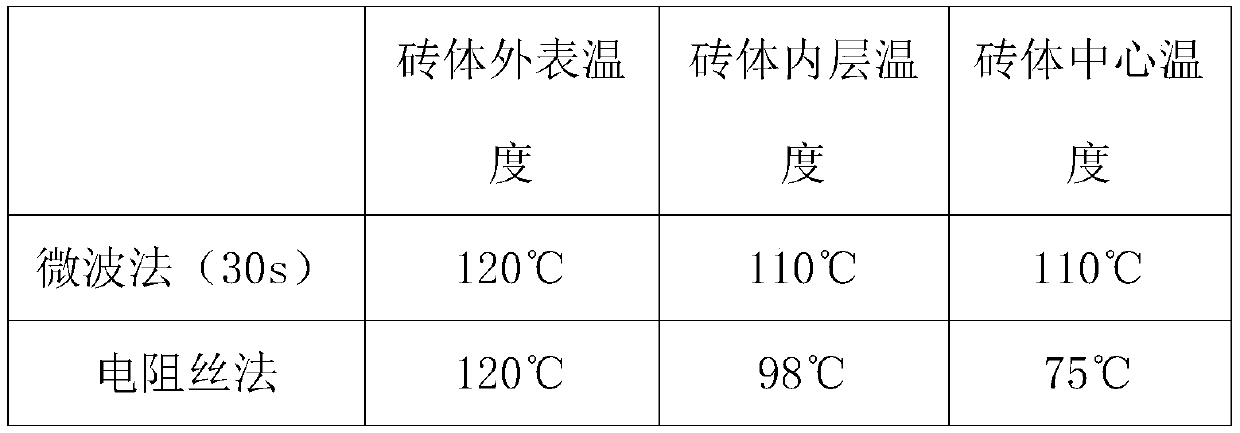

[0063] The paraffin / graphene composite material is injected into the heat storage brick, and the heat is stored in a microwave environment. At the same time, as a comparison, the paraffin / graphene composite material is heated by traditional resistance wire for heat storage.

[0064] Table 2 is the detailed data comparison between the microwave heating heat storage method and the traditional resistance wire heating heat storage method in Experimental Example 1.

[0065] Table 2 Data comparison of heat storage bricks with different heating methods (microwave method and resistance wire method) in Experimental Example 1

[0066]

[0067]

Embodiment 2

[0069] The heat storage system provided in this embodiment includes: a microwave generator and a wave-absorbing phase-change heat-storage brick, the microwave generator is arranged on one side of the wave-absorbing phase-change heat-storage brick, and the wave-absorbing phase-change heat-storage brick It is arranged on both sides of the circulating water for heating, and a composite material is arranged in the wave-absorbing phase-change heat storage brick. Among them, the composite material is Mg(NO3) 2 6H2O / activated carbon composite material, its preparation steps are as follows:

[0070] (1) Take 100g Mg(NO3) 2 6H2O is heated and melted at a temperature higher than its melting point (90°C);

[0071] (2) Add 2g of activated carbon and mix well to make the activated carbon dispersed in the hydrated salt to obtain the hydrated salt / activated carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com