Separator for non-aqueous secondary battery and non-aqueous secondary battery

A secondary battery, non-aqueous technology, used in secondary batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of increased internal resistance and decreased adhesion of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

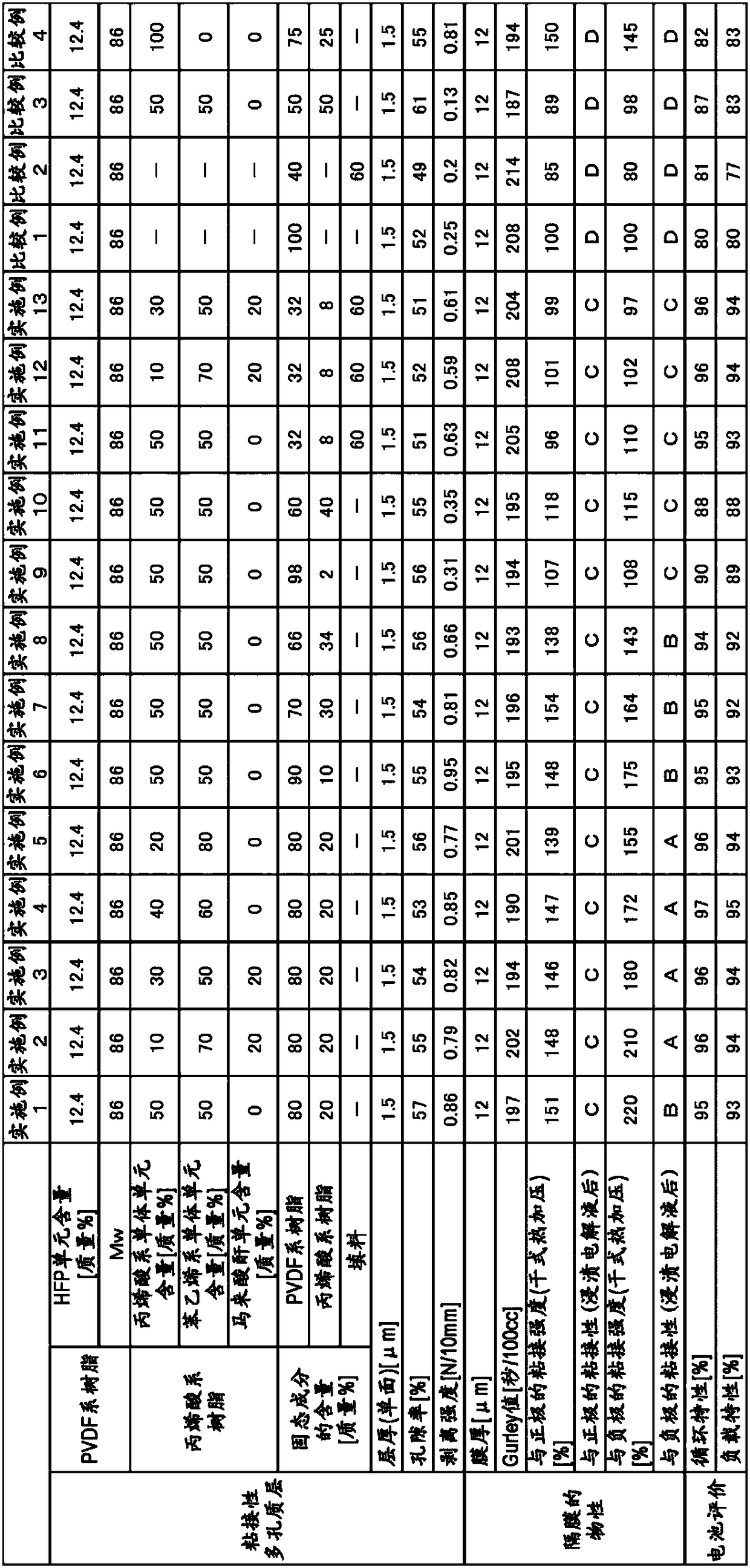

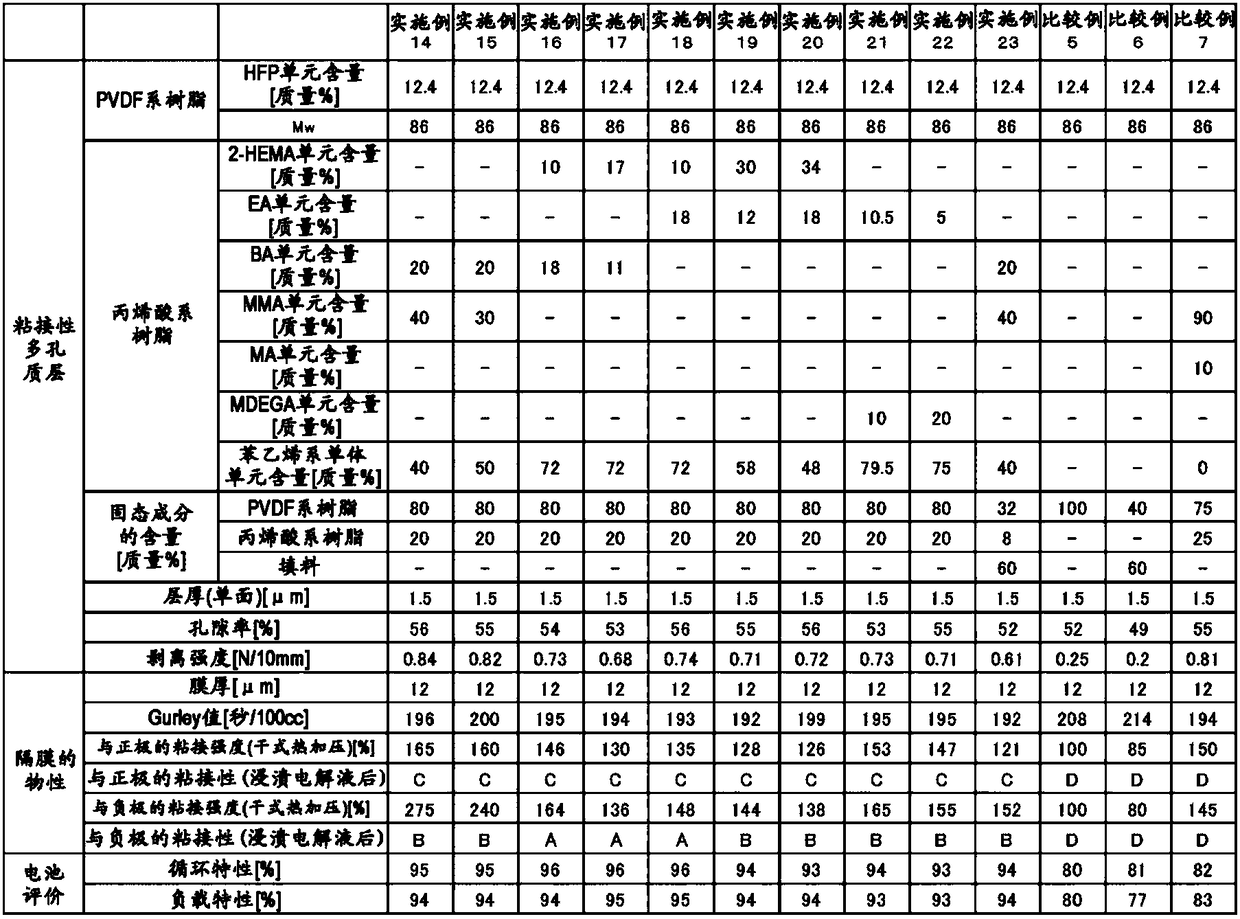

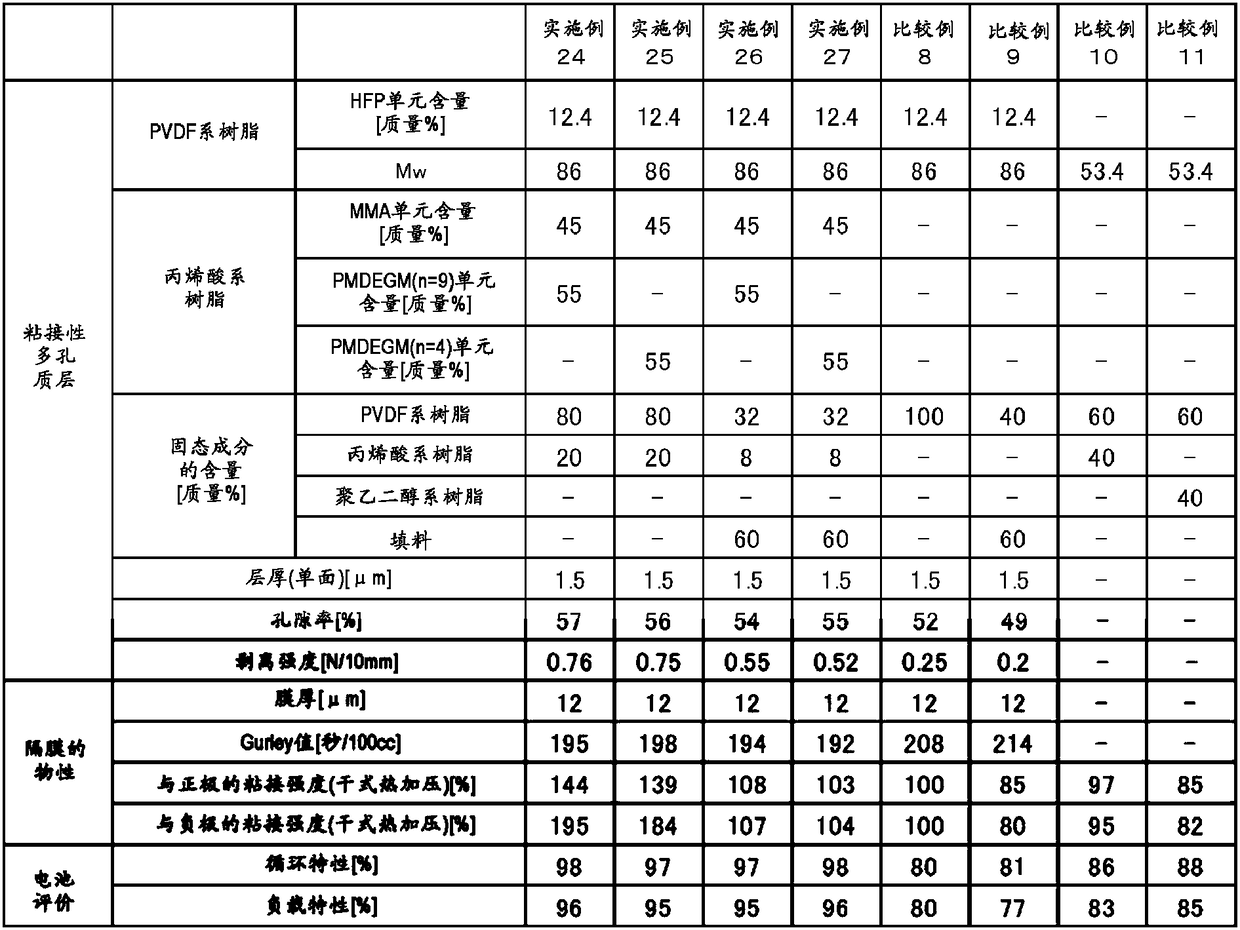

Embodiment 1

[0234] Polyvinylidene fluoride resin (VDF-HFP copolymer, HFP unit content is 12.4% by mass, weight average molecular weight is 860,000) and acrylic resin (methyl methacrylate-styrene copolymer, polymerization ratio [mass Ratio] is 50:50, weight average molecular weight is 115,000, and glass transition temperature is 105 ℃) be dissolved in the mixed solvent of dimethylacetamide and tripropylene glycol (dimethylacetamide: tripropylene glycol=80:20 [mass ratio]), a coating solution for forming an adhesive porous layer was produced. The mass ratio of the polyvinylidene fluoride-based resin and the acrylic resin contained in the coating liquid was 80:20, and the resin concentration of the coating liquid was 5.0% by mass.

[0235] The coating solution was applied to both sides of a polyethylene microporous membrane (film thickness 9.0 μm, Gurley value 150 sec / 100 cc, porosity 43%) as a porous substrate (in this case, the surface and the back surface Coated so that the coating amoun...

Embodiment 2

[0237] The acrylic resin was changed to a terpolymer of methyl methacrylate-styrene-unsaturated carboxylic acid anhydride (polymerization ratio [mass ratio] 10:70:20, weight average molecular weight 113,000, glass transition temperature was 130° C.), except that, it was carried out in the same manner as in Example 1 to produce a separator.

Embodiment 3

[0239] The acrylic resin was changed to a terpolymer of methyl methacrylate-styrene-unsaturated carboxylic acid anhydride (polymerization ratio [mass ratio] of 30:50:20, weight average molecular weight of 130,000, glass transition temperature was 115° C.), except that, it was carried out in the same manner as in Example 1 to produce a separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com