Double-sandwich-layer annular hearth for three-cyclone biomass gasification combustor

A double-layer, burner technology, applied in the field of block, flake, and segment wood fuel, can solve the problems of thick ignition flue gas, insufficient gasification reduction, low calorific value conversion rate, etc., so as to improve combustion-supporting efficiency, The effect of simplifying temperature control and avoiding clinker clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

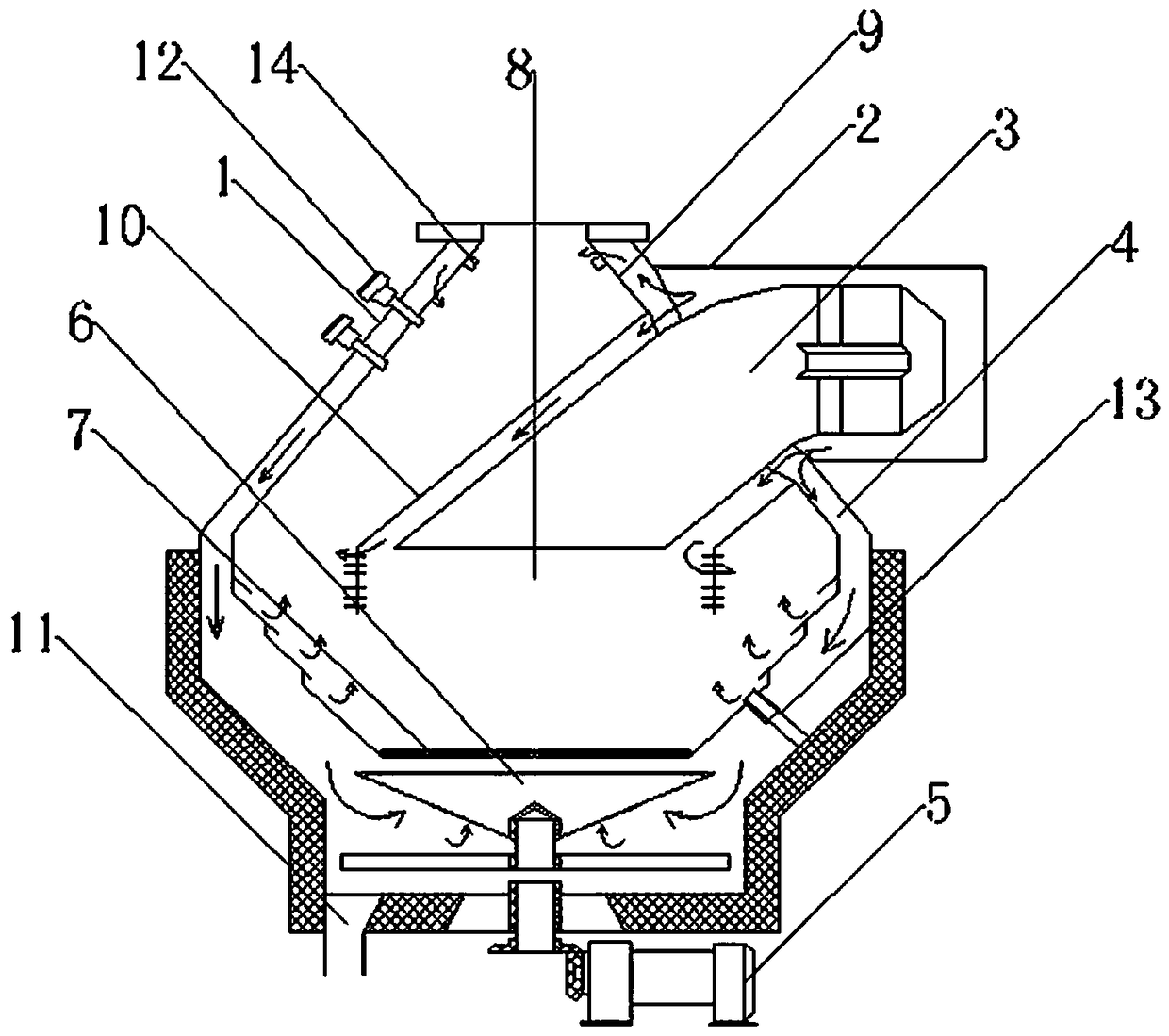

[0023] The present invention provides a double-interlayer annular furnace for a three-swirl biomass gasification burner such as figure 1 As shown, it includes a double-interlayer annular furnace wall 1, an air swirling outer cylinder 2, a fire outlet 3, an interlayer channel 4, a gear motor 5, a grate 6, a horizontal air duct 7, a shrinking reduction chamber 8, and an outer interlayer 9 , the inner interlayer 10 and the ash outlet 11 are characterized in that: the two ends of the horizontal air duct 7 are fixed on the furnace wall, the outer interlayer 9 and the inner interlayer 10 are evenly distributed with air holes, and the grate 6 is also evenly distributed with vertical air holes. The grate hole is straight through, and there are also air holes evenly distributed on the wall of the shrinking reduction chamber 8. The double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com