Fusible-alloy pressure relief device for high pressure gas

A fusible alloy and high-pressure gas technology, applied in the direction of valve devices, safety valves, engine components, etc., can solve problems such as leakage of fusible alloy plugs, accidents, and easy creep of fusible alloys, etc., to reduce pressure, The effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

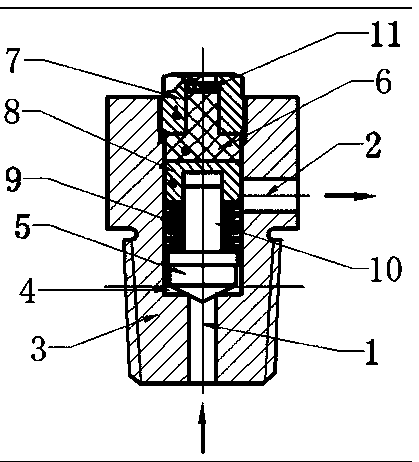

[0017] The high-pressure gas fusible alloy pressure relief device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] As shown in the figure, the high-pressure gas fusible alloy pressure relief device of the present invention includes a metal plug body 3 having a pressure relief inlet passage 1 and a pressure relief outlet passage 2, and the pressure relief inlet passage 1 is arranged at the bottom of the plug body and is connected with the container The inner cavity is connected, and the pressure relief outlet channel 3 is arranged on the side wall of the plug body. It can be seen from the figure that the pressure relief inlet channel 1 and the pressure relief outlet channel 2 are arranged at 90 degrees. The connection thread for connection, the connection thread section forms a base for installation with the container, the middle part of the plug body 3 has a component placement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com