Root-planting agent interface building waterproof layer construction and construction method thereof

A technology for building waterproofing and construction methods, applied in building structures, buildings, roof coverings, etc., can solve the problems of difficult maintenance of interface treatment materials, insufficient penetration depth, surface color effects, etc., and achieve excellent bonding effect, The effect of low construction cost, improved waterproof performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

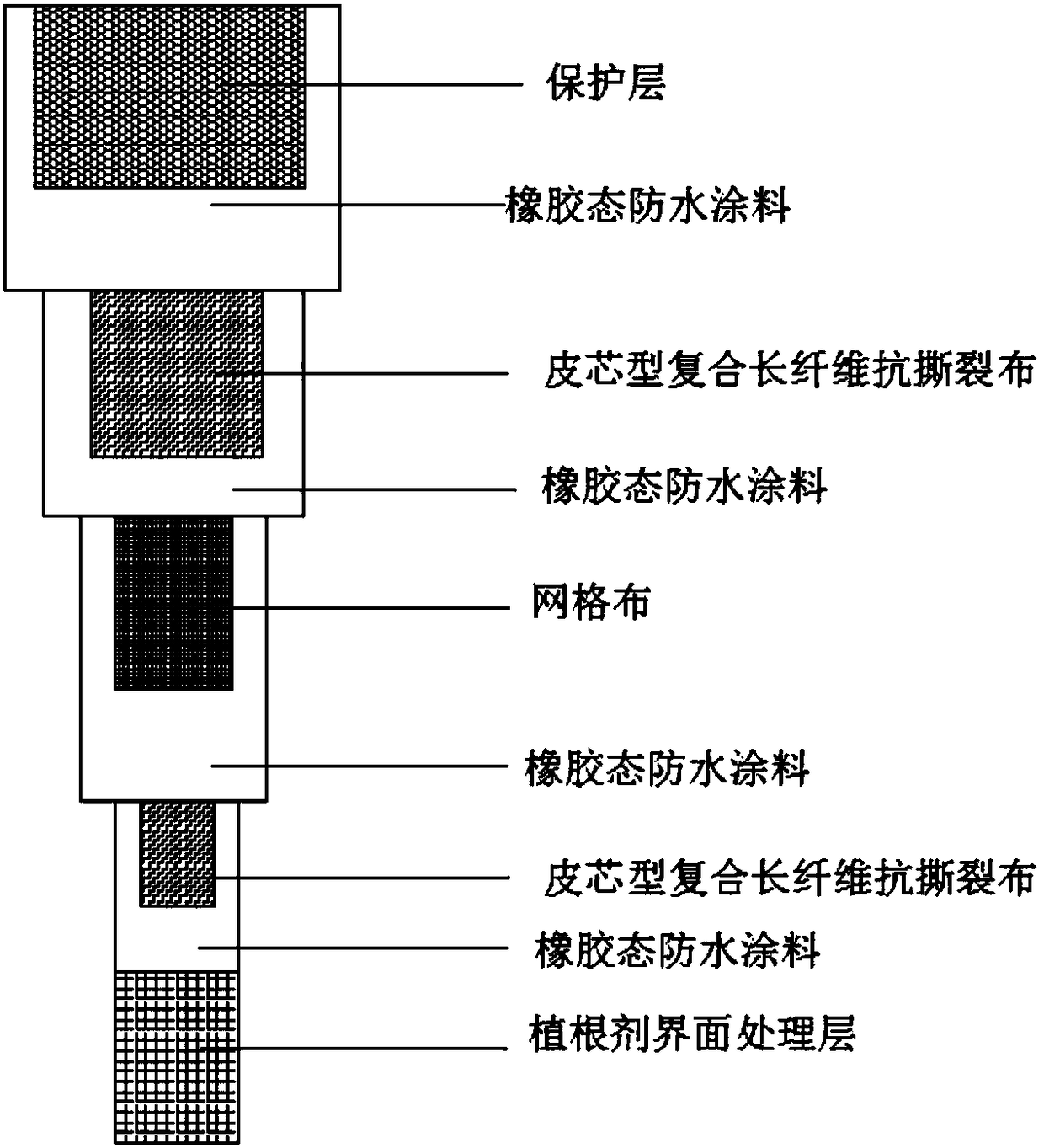

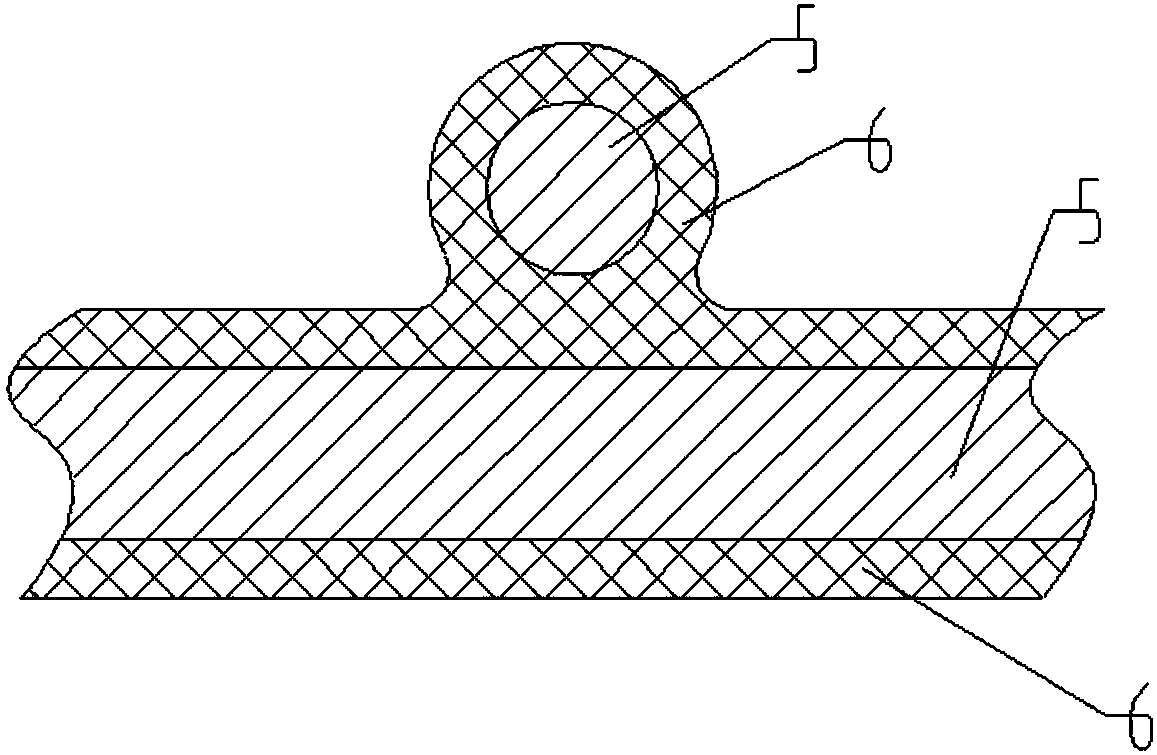

Embodiment 1

[0033] The waterproof layer structure of the present embodiment is a 3-layer structure, 1 layer of rooting agent interface treatment layer, 1 layer of rubber state waterproof coating layer and 1 layer of carcass. Wherein, the rooting agent is magnesium fluorosilicate, and the weight ratio with water is 1:5, and the carcass is 100g / m 2 Sheath-core composite long-fiber tear-resistant cloth. Construction by the following methods:

[0034] Clean up the base surface, remove the laitance and soft objects on the base surface, sweep away the dust, and rinse with water; then use magnesium fluorosilicate and water to make a uniform solution in a weight ratio of 1:5, and then sprinkle it evenly Spread it on the base surface and keep it wet for 24 hours; after the reaction is completed, rinse the rooting agent remaining on the base surface with water; use a brush to apply the rubber-like waterproof coating on the large-area base surface, tube roots, and detailed nodes of the male and fem...

Embodiment 2

[0036] The waterproof layer structure of the present embodiment is a 3-layer structure, 1 layer of rooting agent interface treatment layer, 1 layer of rubber state waterproof coating layer and 1 layer of carcass. Wherein, the rooting agent is sodium fluorosilicate, and the weight ratio with water is 1:5, and the carcass is 100g / m 2 Sheath-core composite long-fiber tear-resistant cloth. Construction method is referring to embodiment 1.

Embodiment 3

[0038] The waterproof layer structure of the present embodiment is a 3-layer structure, 1 layer of rooting agent interface treatment layer, 1 layer of rubber state waterproof coating layer and 1 layer of carcass. Wherein, rooting agent is sodium silicate, and the weight ratio with water is 1:5, and carcass is 100g / m 2 Sheath-core composite long-fiber tear-resistant cloth. Construction method See embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com